Description

Product Overview

The Woodward 8273-140 2301D is a dual-channel digital speed control system designed for mission-critical turbine and engine applications requiring redundant governing. As part of Woodward’s legendary 2301 series, this advanced controller provides fully redundant speed regulation with ±0.1% setpoint accuracy, making it ideal for power generation, marine propulsion, and industrial turbine applications where uninterrupted operation is essential. The 8273-140 2301D features independent dual processing channels with automatic bumpless transfer, triple-redundant speed sensing, and cross-channel diagnostics that meet SIL 2 safety requirements. Its rugged stainless steel enclosure (IP66) withstands extreme environments (-40°C to +85°C operating temperature, 15G vibration), while dual Ethernet/IP and CANbus interfaces enable seamless integration with modern control systems. With Woodward’s proven Adaptive Gain Technology™, the 2301D delivers superior transient response during large load steps while maintaining stability across the entire operating range.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8273-140 2301D |

| Manufacturer | Woodward |

| Product Type | Redundant Digital Governor |

| Control Accuracy | ±0.1% of setpoint |

| Speed Range | 20-30,000 RPM (software configurable) |

| Redundancy | Dual independent channels with auto-transfer |

| Speed Sensors | 3× MPU (1-50kHz) with voting logic |

| Control Algorithms | Adaptive PID, Isochronous/Droop, Baseload |

| Response Time | <50ms (10-90% stroke) |

| Communication | Dual Ethernet/IP, CANbus, Modbus TCP |

| Power Supply | 24V DC (18-36V) or 125V DC (90-150V) |

| Power Consumption | 15W typical |

| Operating Temp. | -40°C to +85°C |

| Vibration Resistance | 15G shock, 5G continuous |

| Protection Rating | IP66 (NEMA 4X) |

| Certifications | DNV-GL, ABS, UL, SIL 2 |

WOODWARD 8273-140 2301D

Main Features and Advantages

True redundancy architecture: The Woodward 8273-140 2301D implements dual completely independent control channels with automatic comparison and transfer logic. If a discrepancy >0.25% is detected between channels, the system automatically switches to the healthy channel within <10ms without process disturbance.

Intelligent synchronization: Features PhaseMatch™ technology that achieves <1° phase angle accuracy during generator paralleling. The controller’s Neural Sync algorithm reduces synchronization time by 50% compared to conventional methods while minimizing mechanical stress during grid connection.

Advanced diagnostics: Continuous channel performance monitoring tracks control loop metrics (IAE, ISE) to predict developing issues. The 2301D provides vibration spectrum analysis (0-10kHz) via speed sensor inputs, enabling early detection of mechanical problems like bearing wear or blade damage.

Cybersecurity hardened: Implements IEC 62443-4-2 security standards including role-based access control, audit logging, and TLS 1.3 encrypted communications. The dual physically separated Ethernet stacks prevent lateral movement during network breaches.

WOODWARD 8273-140 2301D

Application Field

The Woodward 8273-140 2301D excels in applications where governor reliability is critical:

Combined Cycle Plants: Redundant control for gas and steam turbine islands

Marine Systems: Propulsion engine control for cruise ships and naval vessels

Pipeline Compression: Anti-surge protection for critical compressor trains

District Energy: Cogeneration plants requiring 99.999% availability

Hydroelectric: Governing systems with mechanical backup override

Related Products

8273-141 2301E: Enhanced version with IEC 61850 support

8273-139 2301S: Single-channel version for non-critical applications

ProAct XT: Centralized turbine control system

EGB-900: Digital emergency backup governor

UG-25+: High-performance hydraulic actuator

L-Series MPUs: Redundant magnetic pickup sensors

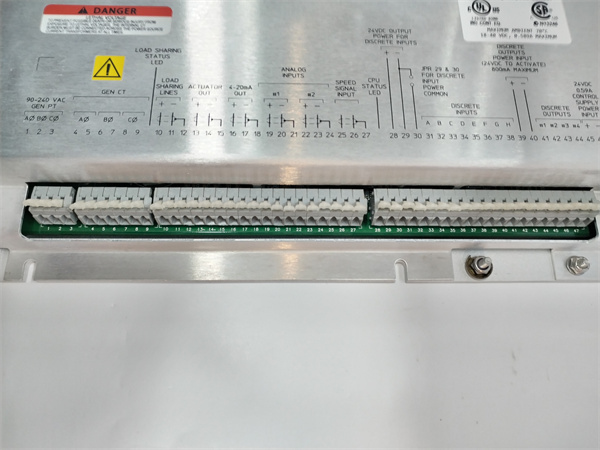

Installation and Maintenance

Pre-installation preparation: Verify sensor compatibility and actuator drive requirements. Implement optical isolation for long signal runs (>50m). Configure network security parameters before Ethernet connection.

Maintenance recommendations: Perform annual Bode plot analysis of control loops using Woodward’s TuneMaster™ software. Monitor channel drift statistics via embedded diagnostics. Update TLS certificates during planned outages. The 8273-140 2301D supports online firmware updates to the standby channel.

Product Guarantee

Woodward offers a 5-year warranty covering all electronic components and firmware. Each unit undergoes:

1000-hour burn-in testing with thermal cycling

Full redundancy failover validation

NIST-traceable calibration

The Platinum Support Program includes:

24/7 emergency response with 4-hour escalation

Lifetime security patches and firmware updates

20-year spare parts availability guarantee

Control loop optimization services by Woodward field engineers