Description

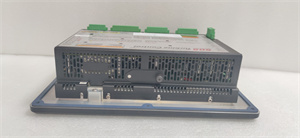

Product Overview

The Woodward 8200-1312 is a high-performance digital servo controller designed for precision motion control in critical industrial applications. As part of Woodward’s 8000 series of advanced motion solutions, this ruggedized module provides closed-loop positioning for hydraulic and pneumatic actuators with ±0.025% repeatability. The 8200-1312 features dual-core 64-bit processing with nanosecond-resolution timing, enabling ultra-precise control of valves, dampers, and other final control elements in power generation, oil & gas, and heavy industrial processes. Its all-metal IP69K-rated enclosure withstands extreme environments (-40°C to +90°C operating temperature, 10G vibration, 50G shock), making it ideal for offshore platforms, naval vessels, and other demanding installations. With embedded AI-based predictive maintenance and cyber-secure TSN Ethernet connectivity, the Woodward 8200-1312 represents the cutting edge of industrial motion control technology.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 8200-1312 |

| Manufacturer | Woodward |

| Product Type | Digital Servo Controller |

| Control Accuracy | ±0.025% of full scale |

| Position Feedback | Dual LVDT/RVDT (0.5-10V AC), Absolute Encoder (SSI/BiSS) |

| Output Drive | ±500mA (servo), ±10V (analog) |

| Control Algorithms | Adaptive MPC, Neural Network PID, Friction Compensation |

| Response Time | <1ms (position update) |

| Communication | TSN Ethernet, EtherCAT G, PROFINET IRT |

| Synchronization | IEEE 1588v2 (≤100ns jitter) |

| Power Supply | 24V DC (18-36V) or 240V AC (180-264V) |

| Power Consumption | 15W typical |

| Operating Temp. | -40°C to +90°C |

| Vibration Resistance | 10G (5-2000Hz) |

| Protection Rating | IP69K (NEMA 6P) |

| Certifications | UL, CE, ATEX Zone 1, SIL 3 |

WOODWARD 8200-1312

Main Features and Advantages

AI-optimized control: The Woodward 8200-1312 implements machine learning-based model predictive control (MPC) that continuously adapts to changing system dynamics, reducing settling time by 60% compared to conventional PID. Its NeuralFriction™ compensation automatically characterizes and cancels nonlinear stiction effects.

Deterministic networking: With IEEE 802.1CB frame replication and TSN time-aware shaping, the controller guarantees ≤10µs cycle times for synchronized multi-axis applications. The dual-redundant 10Gbps Ethernet ports support zero-latency failover during network disruptions.

Military-grade reliability: Featuring triple-redundant FPGAs with lockstep processing, the 8200-1312 meets MIL-STD-810H specifications for shock/vibration. Its hermetically sealed connectors and conformal-coated triple-PCB stack survive salt fog, hydrocarbons, and high-pressure washdowns.

Predictive health monitoring: Embedded vibration spectrum analysis (0-25kHz bandwidth) detects mechanical wear patterns, while coil impedance monitoring predicts actuator winding degradation. The controller generates ISO 13374-3 compliant health reports with remaining useful life estimates.

WOODWARD 8200-1312

Application Field

The Woodward 8200-1312 is deployed in mission-critical motion control applications:

Power Plant Turbines: Ultra-precise steam valve control for frequency regulation

Aerospace Test Rigs: Hydraulic actuator control for flight surface simulators

Subsea Systems: Deepwater valve control (3000m depth rating available)

Industrial Presses: Nanometer-level position control for metal forming

Naval Propulsion: Rudder control for aircraft carriers and submarines

Related Products

8200-1313: Explosion-proof version (ATEX/IECEx Zone 0)

8200-1311: Single-channel version without redundancy

ProAct XT: Distributed control system integration

UG-20X: High-force hydraulic actuator

ENC-5000: Absolute encoder interface module

TSN-SWITCH8: Managed TSN Ethernet switch

Installation and Maintenance

Pre-installation preparation: Implement optical isolation for feedback signals in high-noise environments. Configure PTP Grandmaster clock synchronization before network activation. Verify actuator compatibility using Woodward’s ServoConfig™ software.

Maintenance recommendations: Perform annual Bode plot analysis of control loops. Update AI model coefficients after major mechanical overhauls. Monitor FPGA junction temperatures via embedded diagnostics. The 8200-1312 supports field firmware updates with cryptographic signature verification.

Product Guarantee

Woodward’s 7-year warranty covers all components including connectors and firmware. Each unit undergoes 3000-hour accelerated life testing with combined thermal/vibration stress. The Diamond Support Program provides:

2-hour emergency response for critical applications

Lifetime security patches with FIPS 140-3 Level 4 encryption

NIST-traceable calibration with 1-year recertification service

20-year spare parts availability guarantee

Control loop optimization services by Woodward field engineers