Description

Product Overview

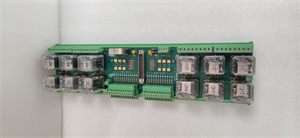

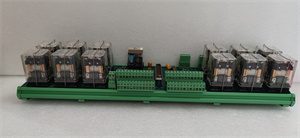

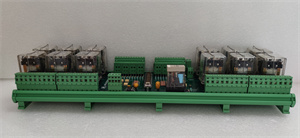

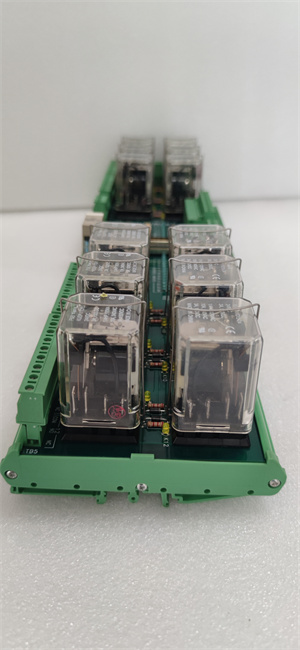

The Woodward 5441-693 is a high-density analog I/O module designed for integration with Woodward’s ProAct® series of distributed control systems. This rugged industrial module provides 16 channels of configurable analog input/output with 24-bit resolution and galvanic isolation, making it ideal for precision monitoring and control in power generation, oil & gas, and heavy industrial applications. The 5441-693 supports universal channel configuration, allowing each point to be independently programmed as voltage (0-10V), current (4-20mA), thermocouple, RTD, or resistance input. Its dual-redundant fieldbus communication (Profibus DP and Modbus RTU) ensures reliable data transmission even in electrically noisy environments. Built to withstand extreme conditions (-40°C to +85°C operating temperature, 5G vibration), the module features conformal-coated electronics and gold-plated connectors for maximum reliability in mission-critical control systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 5441-693 |

| Manufacturer | Woodward |

| Product Type | Analog I/O Module |

| Channels | 16 (universal configurable) |

| Resolution | 24-bit ADC, 16-bit DAC |

| Input Types | 0-10V, 4-20mA, TC (J/K/T/E), RTD (PT100/1000), Ω |

| Output Types | 0-10V, 4-20mA (sourced/sunk) |

| Isolation | 1500V channel-to-channel, 2500V field-to-system |

| Accuracy | ±0.05% of span (voltage/current), ±0.2°C (temperature) |

| Communication | Dual Profibus DP (MBP), Modbus RTU (RS-485) |

| Update Rate | 10ms (all channels) |

| Power Supply | 24V DC (18-36V), 1.5A max |

| Operating Temp. | -40°C to +85°C |

| Dimensions | 120 × 80 × 40 mm (W×H×D) |

| Certifications | UL, CE, ATEX Zone 2, DNV-GL |

WOODWARD 5441-693

Main Features and Advantages

Universal channel flexibility: Each of the 16 channels on the Woodward 5441-693 can be individually configured through software as analog input or output, supporting 9 different signal types without hardware changes. This dramatically reduces spare parts inventory requirements.

Advanced signal conditioning: The module features 24-bit Σ-Δ ADCs with programmable low-pass filtering (1Hz to 10kHz) to eliminate noise in sensitive measurements. Built-in lead resistance compensation for RTDs and cold junction compensation for thermocouples ensure laboratory-grade accuracy in field conditions.

Fault-tolerant architecture: Dual self-monitoring power supplies and watchdog timers guarantee continuous operation. The 5441-693 implements channel-level diagnostics that detect open circuits, shorts, and out-of-range conditions, triggering configurable alarms in the control system.

Seamless system integration: Native support for Profibus DP-V1 enables cyclic and acyclic communication, while the dual-port RS-485 interface allows daisy-chaining of multiple modules. The Woodward 5441-693 automatically synchronizes with ProAct® controllers for deterministic control loop execution.

WOODWARD 5441-693

Application Field

The Woodward 5441-693 excels in applications requiring high-density precision analog I/O:

Power Plant Control: Turbine bearing temperature monitoring (RTD inputs), governor valve positioning (4-20mA outputs)

Compressor Stations: Suction/discharge pressure monitoring, anti-surge valve control

Marine Systems: Shaft power measurement, thruster motor temperature monitoring

Process Industries: Batch reactor temperature control, flow meter interfacing

Hydroelectric Plants: Gate position feedback, vibration monitoring

Related Products

5441-694: 32-channel version with Ethernet/IP

5441-692: 8-channel intrinsically safe version (ATEX Zone 1)

ProAct XT: Main controller for 5441-693 integration

5403-221: Digital input module companion unit

FBM-242: Foundation Fieldbus interface module

PCD-2400: Legacy I/O system upgrade path

Installation and Maintenance

Pre-installation preparation: Verify grounding integrity (<1Ω to chassis ground) and cable shielding (90% coverage minimum). Configure Profibus node addresses and baud rates before power-up. Allocate 50mm clearance for heat dissipation in high-density panels.

Maintenance recommendations: Perform annual calibration verification using NIST-traceable references. Clean DIN rail contacts every 2 years with electronic-grade cleaner. Monitor channel drift statistics via embedded diagnostics to predict sensor degradation. The 5441-693 supports hot-swapping when using redundant communication paths.

Product Guarantee

Woodward provides a 5-year warranty for the 5441-693, covering all electronic components including connectors. Each module undergoes 1000-hour burn-in testing with full functional validation at temperature extremes. The Lifetime Support Program guarantees firmware updates and security patches for 15+ years, with 24/7 technical support from Woodward’s global response centers. Calibration certifications include ISO 17025 traceability with recommended 3-year recalibration intervals.