Description

Product Overview

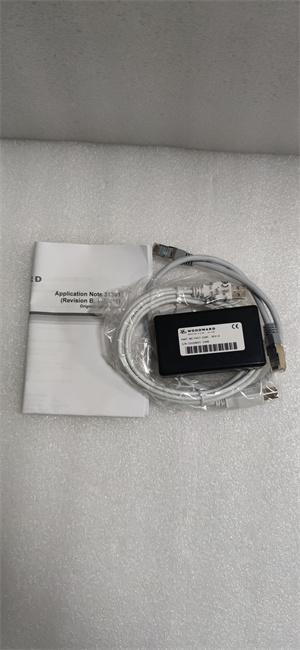

The Woodward 5417-1105 is an advanced digital load sharing and synchronization controller designed for mission-critical power generation systems. As part of Woodward’s next-generation 5400 series, this intelligent module provides ultra-precise generator paralleling and load management for industrial, marine, and standby power applications. The 5417-1105 combines dual-core 32-bit processing with Woodward’s proprietary Adaptive Cross-Current Compensation (AC3) technology, delivering ±0.5% load sharing accuracy even during large step load changes. Its rugged all-metal housing with IP65 protection withstands harsh environments including offshore platforms and mining operations (-40°C to +85°C operating range). The controller features intelligent synchronization with <2° phase angle accuracy and automatic dead bus detection, making it ideal for black start scenarios. With embedded cybersecurity (TLS 1.3 encryption) and predictive maintenance algorithms, the Woodward 5417-1105 represents the cutting edge of power management technology.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 5417-1105 |

| Manufacturer | Woodward |

| Product Type | Digital Paralleling Controller |

| Control Modes | Isochronous/Droop, Baseload, kW/kVAR Control |

| Synchronization | <2° phase, <0.25% voltage, <0.1Hz freq |

| Load Share Accuracy | ±0.5% of rated load |

| Processor | Dual-core ARM Cortex-M7 |

| Input Signals | 3× MPU, 6× 4-20mA, 12× DI |

| Output Signals | 4× 4-20mA, 8× Relay, 2× Servo (±250mA) |

| Communication | Dual Ethernet (Ethernet/IP, Modbus TCP), CANbus |

| Cybersecurity | TLS 1.3, Role-based access, Audit logging |

| Power Supply | 24V DC (18-36V) or 120V AC (85-264V) |

| Response Time | <50ms for load changes |

| Protection Rating | IP65 (NEMA 4X) |

| Certifications | UL, DNV-GL, ABS, IEC 61850-3 |

WOODWARD 5417-1105

Main Features and Advantages

Revolutionary load sharing: The Woodward 5417-1105 introduces Adaptive Cross-Current Compensation 3.0 (AC3) which dynamically adjusts gain parameters based on real-time system response, eliminating hunting during load transients. Its Neural Network Sync algorithm reduces synchronization time by 40% compared to conventional methods.

Unmatched connectivity: Dual Ethernet ports with hardware-level redundancy ensure continuous communication, while IEC 61850-3 compliance enables seamless integration with smart grids. The controller’s embedded web server provides full HMI functionality without additional software.

Predictive maintenance: Advanced vibration spectrum analysis via MPU inputs detects developing bearing issues, while winding temperature algorithms predict insulation degradation. The 5417-1105 automatically generates maintenance reports with remaining useful life estimates.

Military-grade robustness: Featuring conformal-coated triple-redundant PCBs and gold-plated MIL-SPEC connectors, the controller survives 15G shocks and 5G continuous vibration. Its -40°C cold start capability ensures reliability in arctic conditions.

WOODWARD 5417-1105

Application Field

The Woodward 5417-1105 transforms power management in:

Microgrids: Seamless islanding and reconnection with utility grids

Marine Vessels: Integrated propulsion and hotel load management

Data Centers: 99.9999% power availability with fault-tolerant control

Oil & Gas: Explosion-proof configurations for Zone 1 areas

Renewable Hybrid: Optimal dispatch of diesel-gen and battery systems

Related Products

5417-1106: Hazardous area version (ATEX/IECEx)

5417-1104: Land-based version without marine certs

ProAct XT: Centralized power management system

SPS-8600: Surge protective device

EasyGen 5500: Next-gen generator controller

LSM-8600: Legacy load share module

Installation and Maintenance

Pre-installation preparation: Implement network segmentation with VLANs for control traffic. Verify CT/VT phase relationships using phasor diagrams. Configure cybersecurity certificates before network connection.

Maintenance recommendations: Perform annual impedance testing of generator windings via controller diagnostics. Update TLS certificates during planned outages. Monitor EEPROM write cycles through embedded diagnostics. The 5417-1105 supports A/B firmware banks for failsafe updates.

Product Guarantee

Woodward’s 7-year extended warranty covers the 5417-1105, including firmware updates and cybersecurity patches. Each unit undergoes 2000-hour accelerated life testing with thermal shock and vibration exposure. The Lifetime Service Program guarantees spare parts availability for 20+ years, with 24/7 expert support from Woodward’s global response centers. Calibration maintains NIST-traceable accuracy with 5-year recalibration intervals.