Description

System Role and Integration

The 5X00226G02 serves as the critical interface hub within the Ovation Distributed Control System architecture, functioning as an OCR 400 (Ovation Controller Remote) I/O Interface Module that bridges the communication gap between the central controller and distributed field devices. As a core component of the Ovation I/O subsystem, it mounts in standard Ovation racks and manages the real-time data exchange necessary for process monitoring and control.

This module occupies a foundational position in the Ovation control hierarchy, typically installed in local or remote I/O cabinets where it aggregates signals from field sensors and actuators. Unlike simple I/O cards that handle specific signal types, the 5X00226G02 functions as an intelligent interface processor, coordinating multiple I/O channels and managing communication protocols to ensure seamless integration of diverse field devices into the unified control strategy.

Core Functionality and Signal Handling

The module provides comprehensive I/O interface capabilities, supporting both digital and analog signal processing for connection to sensors, actuators, switches, and intelligent field devices. It handles the physical layer communication via RS-485 interfaces, enabling robust multi-drop networks that can extend over significant distances within industrial facilities. The module processes input signals from field devices—converting physical measurements into digital data for the controller—and manages output signals that drive control elements such as valves, motors, and indicators.

Operating from a 12-24 VDC power supply, the 5X00226G02 incorporates signal conditioning, isolation, and protection circuitry to safeguard the sensitive controller electronics from field-side electrical transients, ground loops, and electromagnetic interference. The module supports standard industrial communication protocols including Modbus RTU, facilitating integration with third-party devices and legacy equipment that must coexist with the Ovation system.

The OCR 400 designation indicates this module’s role in remote I/O architectures, where it can operate as a distributed processing node communicating with the central controller over the Ovation network. This distributed approach allows I/O to be located near field equipment—reducing wiring costs and signal degradation—while maintaining centralized control and monitoring capabilities.

Platform Heritage and Operational Benefits

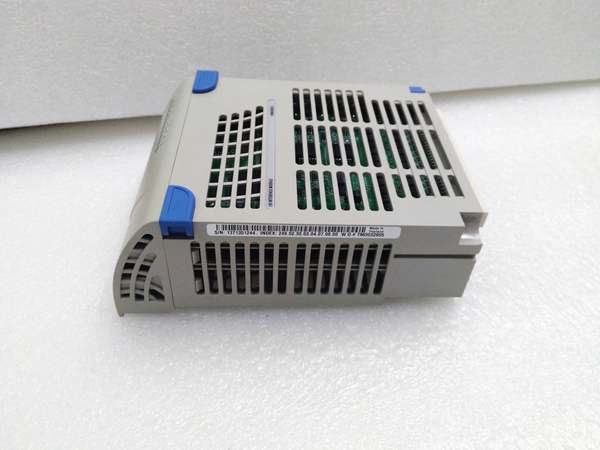

As a component of the Westinghouse Ovation platform now maintained within Emerson’s automation portfolio, the 5X00226G02 reflects the robust design philosophy developed for mission-critical industrial applications. The module’s compact dimensions (12.7 cm × 6.2 cm × 16.2 cm) optimize space utilization in control cabinets, while the lightweight construction (0.34 kg) minimizes mounting system loads and facilitates rapid replacement during maintenance.

The IP20 protection rating provides adequate safeguarding for control room and cabinet installations, preventing finger access to hazardous voltages while allowing ventilation for thermal management. The wide operating temperature range accommodates installations in environments with limited climate control, from heated control rooms to auxiliary equipment enclosures subject to seasonal temperature variations.

Integration with the Ovation system architecture provides seamless compatibility with Ovation controllers, power supplies, and communication modules, ensuring that spare parts are interchangeable and system expansions maintain consistency with existing infrastructure.

WESTINGHOUSE 5X00226G02

Part 4: Technical Specifications

-

Model Number: 5X00226G02

-

Manufacturer: Westinghouse Electric Corporation (Emerson Ovation product line)

-

Product Type: I/O Interface Module (OCR 400 Series)

-

Dimensions: 12.7 cm × 6.2 cm × 16.2 cm (5.0 in × 2.4 in × 6.4 in)

-

Weight: 0.34 kg (0.75 lbs)

-

Operating Voltage: 12-24 VDC

-

Current Consumption: ≤50 mA @ 24 VDC

-

Communication Interface: RS-485 (primary), supporting Modbus RTU protocol

-

I/O Capacity: Variable configuration (supports multiple analog and digital channels depending on system architecture)

-

Operating Temperature: -20°C to +60°C (-4°F to +140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Humidity: 0% to 95% RH (non-condensing)

-

Environmental Rating: IP20 (control cabinet installation)

-

Mounting: Rack-mounted within Ovation DCS chassis

-

Certifications: CE, UL, CSA (depending on configuration)

-

Power Supply: LocalBus +5 VDC at 1.4 A or 24 VDC auxiliary (configuration dependent)

-

Shock: 10g ½ sine wave for 11 ms

-

Vibration: 1mm peak-to-peak (5-16 Hz), 0.5g (16-150 Hz)

-

Airborne Contaminants: ISA-S71.04-1985 Class G3

-

Terminal Block Key Position: D6

-

Status: Available via Emerson certified spares and secondary market

Part 5: Core Features & Customer Value

Robust Communication Interface: The integrated RS-485 communication port provides reliable multi-drop networking capability, enabling the module to communicate with multiple field devices over distances up to 1,200 meters. For industrial facilities with geographically dispersed equipment, this capability eliminates the need for expensive point-to-point wiring while maintaining reliable data transmission through electrically noisy environments.

Modular System Integration: As part of the Ovation OCR 400 series, the module supports hot-swappable replacement (when system configuration permits) and seamless integration with existing Ovation infrastructure. Maintenance organizations can standardize on a single interface module type for diverse I/O applications, reducing spare parts inventory complexity and ensuring that replacement parts are readily available for rapid restoration of failed channels.

Comprehensive Signal Protection: Built-in isolation and surge protection circuitry safeguards the expensive controller backplane from field-side electrical faults. In power generation and heavy industrial environments where lightning strikes, switching transients, and ground faults are common, this protection ensures that a single field wiring fault does not cascade to damage multiple I/O modules or the central controller, significantly reducing repair costs and system downtime.

Flexible I/O Configuration: The module supports both digital and analog signal processing through compatible terminal blocks and personality modules, allowing engineers to mix signal types within the same I/O rack without requiring specialized hardware for each channel. This flexibility proves particularly valuable during system retrofits where existing field wiring must be integrated with modern digital control systems.

Compact High-Density Design: The small footprint (12.7 cm × 6.2 cm × 16.2 cm) maximizes I/O density within standard control cabinets, allowing up to hundreds of I/O points per enclosure. For facilities with limited control room space or those retrofitting legacy systems into existing cabinets, this density enables comprehensive control system upgrades without requiring additional building infrastructure or expanded footprint.

WESTINGHOUSE 5X00226G02

Part 6: Typical Applications

Power Generation Distributed Control: The 5X00226G02 is extensively deployed in coal-fired, gas-fired, and nuclear power plants as the interface between Ovation controllers and field devices monitoring turbine auxiliaries, boiler combustion systems, and balance-of-plant equipment. In these applications, the module aggregates signals from temperature transmitters, pressure switches, and vibration sensors located throughout the unit, providing the controller with real-time data for unit protection and optimization while withstanding the electromagnetic interference prevalent in switchyard environments.

Water and Wastewater Treatment: Municipal and industrial water treatment facilities utilize the module to interface with flow meters, level transmitters, and chemical analyzers distributed across pumping stations, filter galleries, and disinfection systems. The RS-485 communication capability supports multi-drop networks connecting multiple remote sensors, while the rugged construction withstands the humidity and temperature variations common in treatment plant environments.

Oil and Gas Production: In petroleum pipeline, refining, and natural gas processing applications, the module provides the interface between control system processors and field instrumentation including custody transfer meters, emergency shutdown valves, and compressor control systems. The module’s ability to operate in -20°C to +60°C environments accommodates outdoor installations in remote wellhead locations and pipeline compressor stations without requiring climate-controlled enclosures.

Chemical and Petrochemical Processing: Chemical manufacturing facilities employ the 5X00226G02 to monitor reactor temperatures, vessel pressures, and flow rates in batch and continuous process applications. The module’s signal isolation prevents ground loop errors when connecting to sensors located in different grounding zones—such as grounded thermocouples in reactors and floating pressure transmitters in piping systems—ensuring measurement accuracy critical for product quality and safety.

Building Automation and Facility Management: Commercial and industrial facilities integrate the module into building management systems for monitoring HVAC equipment, energy meters, and environmental sensors. The compact size facilitates installation in crowded mechanical rooms, while the Modbus RTU protocol support enables integration with diverse building automation devices from multiple manufacturers within a unified Ovation control platform.