Description

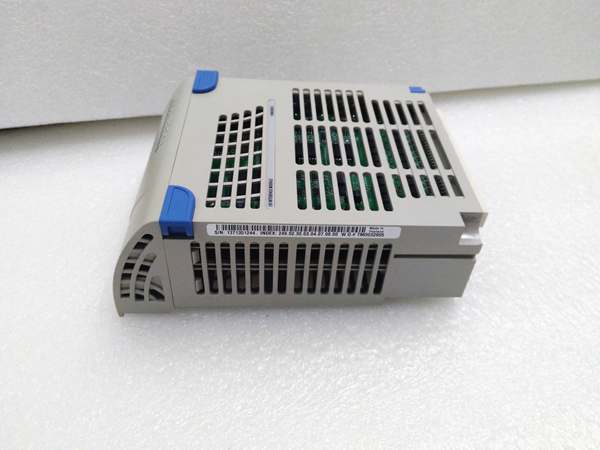

5X00226G02: Product Overview

The 5X00226G02 serves as a critical signal conversion and interface component within the Emerson Ovation Distributed Control System (DCS), a platform with roots tracing back to Westinghouse Electric Corporation’s process control division. In the Ovation architecture, this module occupies a specific role as the final output stage for analog control loops, translating the digital setpoint commands generated by Ovation controllers into the standardized 4-20 mA current signals required by the vast majority of industrial field actuators.

Positioned within the I/O subsystem of the Ovation DCS, the 5X00226G02 typically resides in a local or remote I/O chassis, mounted on a standard Ovation I/O carrier or backplane. Its function is essential for closed-loop process control: it receives digital values from the controller’s algorithm calculations and converts these via internal digital-to-analog converters (DACs) into precise current signals. These signals then traverse field wiring to devices such as control valve positioners, variable frequency drive (VFD) speed references, damper actuators, or chemical dosing pump controllers. The module’s accuracy and resolution directly impact the stability and precision of the control loops it serves, making it a high-reliability component in power generation, water treatment, and petrochemical applications.

As part of the Ovation platform, the 5X00226G02 benefits from the system’s deterministic communication architecture and integrated engineering environment. The Ovation system is renowned for its seamless integration of control, information, and asset management functions, and this module contributes to that ecosystem by providing diagnostic feedback and status indication that feed into the broader system health monitoring capabilities. However, it is important to note that this module represents legacy Ovation I/O technology, predating the current-generation Smart I/O and high-density analog output packs now offered by Emerson.

WESTINGHOUSE 5X00226G02

5X00226G02: Technical Specifications

-

Model Number: 5X00226G02

-

Manufacturer: Emerson Automation Solutions (legacy Westinghouse product line)

-

Product Type: Analog Output Module / I/O Interface Module

-

System Family: Ovation Expert Control System (Ovation 1.x/2.x generation)

-

Number of Channels: 8 analog output channels

-

Output Signal: 4-20 mA DC, sink/source configurable

-

Load Drive Capability: Up to 750 Ω per channel (at 24 V DC loop supply)

-

Accuracy: Typically ±0.1% of span (nominal, when new)

-

Resolution: 12-bit or higher DAC resolution (system-dependent)

-

Update Rate: Approximately 100 ms per channel (varies with system scan rate)

-

Isolation: Channel-to-channel and field-to-system isolation via opto-couplers or isolation amplifiers

-

Diagnostic Features: Per-channel open-circuit detection, overrange/underrange indication, module status LEDs, fault reporting to Ovation Workstation

-

Mounting: Plug-in module for standard Ovation I/O carrier/backplane

-

Operating Temperature: -20°C to +60°C (-4°F to +140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions: Approximately 12.7 cm x 6.2 cm x 16.2 cm (5.0″ x 2.4″ x 6.4″)

-

Weight: Approximately 0.34 kg (0.75 lbs)

-

Certifications: UL, CE, CSA (typical for Ovation I/O modules of this era)

Core Features & Customer Value

Precision Signal Generation for Tight Process Control: The primary engineering value of the 5X00226G02 lies in its ability to generate stable, accurate 4-20 mA signals with minimal drift. In process control applications—whether maintaining boiler drum level, controlling combustion air flow, or regulating chemical feed rates—the fidelity of the output signal directly correlates with process stability and product quality. The module’s specified ±0.1% accuracy ensures that when your controller commands 50% output, the field device receives exactly 12 mA, not 11.8 mA or 12.2 mA. This precision eliminates the “hidden” process variability that accumulates when multiple analog outputs in a loop each contribute small errors.

Robust Isolation and Noise Immunity: Industrial environments are electrically hostile. Variable frequency drives, high-power contactors, and radio frequency sources create ground loops and electromagnetic interference that can corrupt analog signals. The 5X00226G02 incorporates galvanic isolation between channels and between the field side and system side, preventing ground loop currents from affecting signal integrity. For the commissioning engineer, this means fewer headaches with shield grounding schemes and less time troubleshooting erratic valve behavior caused by electrical noise. The isolation also provides a measure of protection for the expensive controller hardware against field-side voltage transients.

Comprehensive Diagnostic Visibility: Unlike simple analog output cards that provide only the output signal, the 5X00226G02 includes per-channel diagnostics that detect open circuits (broken wires), overrange conditions, and module health status. These diagnostics report back to the Ovation Workstation, allowing operators to see “Loop Open” alarms immediately rather than wondering why a valve isn’t moving. For maintenance teams, this translates to faster troubleshooting—knowing whether the problem is a failed positioner, a broken wire, or a faulty output card significantly reduces mean-time-to-repair (MTTR). The front-panel LEDs provide at-a-glance status indication during field commissioning and loop checking.

Legacy Compatibility and Investment Protection: For facilities with existing Ovation installations dating from the late 1990s through early 2010s, the 5X00226G02 represents a form-fit-function replacement that preserves the existing control strategy programming and I/O wiring. This compatibility protects the substantial engineering investment in control logic configuration, graphic displays, and historical data archives. While newer Ovation I/O offers enhanced features, maintaining operational continuity with proven hardware avoids the risks and costs associated with wholesale system migrations during critical production periods.

WESTINGHOUSE 5X00226G02

Typical Applications

Fossil Power Plant Combustion Control: In coal-fired or combined-cycle power plants utilizing Ovation DCS platforms, the 5X00226G02 commonly drives the analog signals to boiler combustion control actuators. Specifically, it provides the 4-20 mA references to forced draft fan inlet vane positioners, fuel valve actuators, and damper drives that regulate the air-fuel ratio. In these applications, the module’s reliability is paramount—a failure during peak load conditions can force a unit derate or trip. The module’s load drive capability (750 Ω) accommodates the long cable runs typical of power plant field wiring without signal degradation.

Municipal Water Treatment Chemical Dosing: Water treatment facilities employing Ovation systems for process automation frequently use the 5X00226G02 to control chemical feed pumps. In coagulation/flocculation processes, precise dosing of alum or polymer based on raw water turbidity requires accurate analog control of variable-speed metering pumps. The module’s isolation protects against the ground potential differences that often exist between the control room and remote chemical buildings, while its open-circuit detection immediately alerts operators if a pump control cable fails.

Petrochemical Distillation Column Control: In refineries and chemical plants with legacy Ovation installations, this module controls the reboiler steam valves and reflux flow control valves on distillation columns. The tight temperature control required for product separation specifications demands that the analog output accurately position control valves across their full stroke. The module’s diagnostic capabilities help distinguish between control valve pneumatic issues and electrical signal problems, reducing unnecessary valve maintenance.

Pulp and Paper Machine Stock Preparation: Paper mills utilizing Ovation DCS for stock preparation and wet end control deploy the 5X00226G02 to regulate consistency control valves, fan pump speed references, and chemical additive flows. The harsh electrical environment of paper machines—with large DC drives and high-power AC motors—demands the noise immunity and isolation features this module provides to prevent sheet weight and moisture control variability.