Description

System Role and Integration

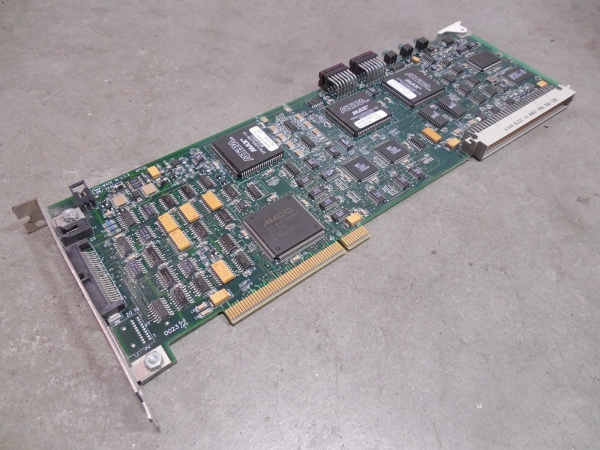

The 4256A84G01 functions as the primary discrete signal acquisition interface within the Westinghouse Q-Line distributed I/O architecture, serving as the critical boundary between field devices and the control system backplane. As a QID (Q-Line Input Discrete) card, it mounts in Q-Line I/O chassis and communicates via the proprietary Q-Line parallel bus, interfacing with the main processor unit to deliver digital status information from field contacts and low-voltage logic sources.

This module occupies a specific position in legacy Westinghouse control systems—primarily deployed in power generation turbine control, boiler management, and process safety applications developed during the 1980s and 1990s. It bridges the gap between 5V logic-level field devices and the higher-voltage internal logic of the Q-Line system, providing essential signal conditioning and isolation that protects sensitive controller electronics from ground faults and electrical transients common in industrial switchyard environments.

Core Functionality and Signal Handling

The card provides sixteen independent isolated input channels, each capable of sensing both dry contact closures and wetted 5VDC or 5VAC voltage sources. This dual-mode capability allows the module to accept inputs from standard limit switches, relay contacts, and solid-state logic devices operating at TTL or 5V CMOS levels. Each channel features individual galvanic isolation rated to withstand 600V AC potential between the field terminal and the internal backplane circuitry—a critical safety feature when monitoring devices in high-voltage auxiliary cabinets or switchgear compartments.

Individual channel LEDs on the card face provide immediate visual indication of input state, enabling technicians to verify field wiring integrity and device status without requiring software interrogation or portable test equipment. The module converts the discrete field signals into digital data packets transmitted across the Q-Line bus, where the main control processor interprets the states for interlock logic, sequence control, and alarm annunciation.

Platform Heritage and Operational Benefits

As a component of the Q-Line I/O family—the direct predecessor to the modern Ovation distributed control system—the 4256A84G01 represents the ruggedized design philosophy developed for mission-critical power plant applications. The Q-Line architecture established the foundation for the distributed I/O concepts later integrated into the Ovation platform, emphasizing modularity, high-density channel packing, and comprehensive isolation.

The 5VDC input specification specifically addresses the needs of interfacing with early solid-state sensors, microprocessor-based protective relays, and TTL-compatible logic systems common in legacy turbine generator controls and auxiliary system automation. Unlike later 24VDC or 125VDC field input standards, this card serves specialized applications where 5V logic predominates, such as early digital protective relay interfaces, solid-state trip circuits, or integration with third-party microprocessor-based subsystems requiring low-voltage logic compatibility.

Westinghouse 4256A84G01

Part 4: Technical Specifications

-

Model Number: 4256A84G01

-

Manufacturer: Westinghouse Electric Corporation (Process Control Division)

-

Product Type: Q-Line Input Discrete Card (QID)

-

Input Channels: 16 isolated discrete inputs

-

Input Voltage Range: 5V DC nominal (4V minimum ON, 0.9V maximum OFF), 5V AC compatible

-

Input Current: 10mA maximum (ON state), 15mA minimum (ON state for wet contact sensing)

-

Isolation Rating: 600V AC withstand (channel-to-ground and channel-to-channel), one minute duration

-

Input Type: Dry contact or wetted voltage (5V sourcing)

-

Signal Format: Single-ended inputs, logic-oriented threshold detection

-

Status Indication: Individual LED per channel (front panel)

-

Backplane Interface: Q-Line proprietary parallel bus (Q-rack compatible)

-

Power Consumption: 1.75W maximum (all channels ON)

-

Operating Temperature: 0°C to 60°C (32°F to 140°F)

-

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

-

Mounting: Plug-in card for Q-Line I/O chassis

-

Compatible Replacements: Functionally interchangeable with WID07A (Fieldbus Module equivalent)

Part 5: Core Features & Customer Value

High-Density Isolated Input Architecture: The sixteen-channel configuration maximizes I/O density within the Q-Line chassis, reducing the per-point hardware cost and cabinet space requirements compared to lower-density alternatives. For plant engineers managing retrofits of legacy turbine control systems, this density allows replacement of obsolete input hardware without requiring additional cabinet real estate or expanding the I/O footprint.

Galvanic Isolation for Ground Loop Prevention: The 600V isolation rating between each input channel and the controller backplane eliminates ground loop currents that can cause erratic logic behavior or damage sensitive microprocessor-based controllers. In power generation environments where large ground potential differences exist between switchyard equipment and control room electronics, this isolation ensures reliable sensing of auxiliary contact status without introducing noise or safety hazards into the control system.

Dual-Mode Input Compatibility: The card’s ability to sense both dry contacts and wetted 5V sources provides application flexibility without hardware configuration changes. Maintenance organizations can standardize on a single spare card for diverse applications—from monitoring dry relay contacts in breaker auxiliary cabinets to interfacing with active 5V logic outputs from early digital protective relays or microprocessor-based turbine supervisory instruments.

Immediate Visual Diagnostics: Individual LED indicators for each input channel enable rapid troubleshooting without requiring engineering workstation access or specialized diagnostic software. Technicians performing field checkout or investigating alarm conditions can verify input states directly at the card face, significantly reducing mean time to repair (MTTR) during maintenance outages and eliminating the need for portable test equipment in energized panels.

Legacy System Continuity: As original Q-Line components are no longer in production, availability of the 4256A84G01 through the secondary market provides critical sparing for facilities operating mature control systems. This continuity allows power plants and industrial facilities to maintain regulatory compliance and operational reliability while deferring costly total system migrations until planned capital improvement cycles.

4256A84G01

Part 6: Typical Applications

Turbine Generator Protective Relay Interface: The 4256A84G01 is extensively utilized in legacy Westinghouse turbine control systems to monitor the status of electromechanical and early solid-state protective relays. In hydrogen-cooled generator installations, the card senses 5V logic outputs from stator ground fault relays, differential protection schemes, and bearing vibration trip circuits, providing the control system with immediate indication of protective device status without requiring external interposing relays or signal converters.

Boiler Burner Management Discrete Inputs: Within fossil fuel power plant combustion control systems, this module monitors low-voltage limit switches and flame scanner logic outputs in burner front cabinets. The 5V input capability interfaces directly with the logic-level outputs of early flame detection systems and fuel valve position switches, feeding the burner management system (BMS) with the discrete status signals required for light-off sequences and fuel safety interlocks.

Turbine Supervisory Instrumentation (TSI) Integration: In legacy TSI systems employing 5V TTL logic for vibration, eccentricity, and differential expansion monitoring, the card accepts logic-level alarm and trip outputs from proximity probe monitors and shaft-riding position sensors. The high-speed input response characteristics support the rapid protection requirements of overspeed detection and thrust bearing wear monitoring systems.

Switchyard Auxiliary Control: The module finds application in remote Q-Line termination cabinets located in 480V motor control centers (MCCs) and switchgear lineups, where it monitors the status of breaker auxiliaries, ground fault sensors, and interposing relay coils operating at 5V logic levels. The 600V isolation rating provides necessary protection for the control system backplane when monitoring devices located in high-voltage switchyard environments subject to switching transients and ground potential rise during fault conditions.

Early Digital Control System Retrofits: During partial modernization projects where legacy Q-Line systems interface with early upgrades, the 4256A84G01 serves as the input interface for microprocessor-based subsystems—such as early programmable logic controllers (PLCs) or single-loop digital controllers—that communicate status via 5V logic signals rather than traditional contact closures.