Description

System Role and Integration

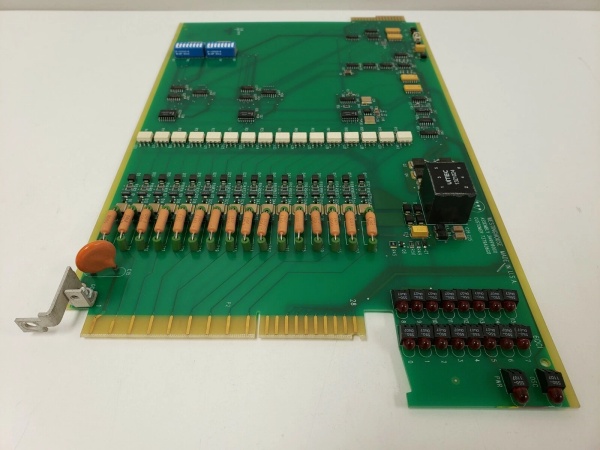

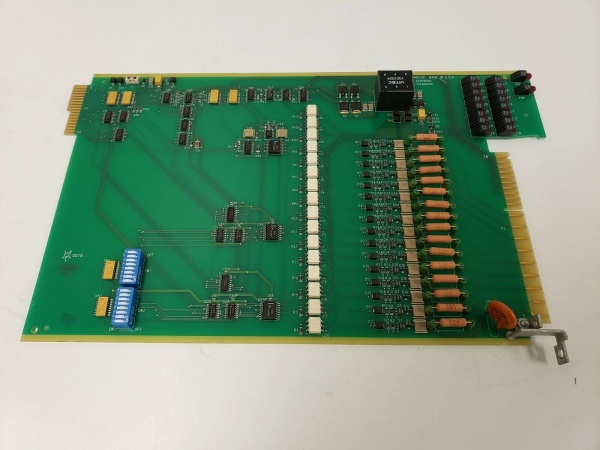

The 3A99160G02 serves as the primary discrete input interface for dry contact sensing within the Westinghouse Q-Line distributed control architecture, functioning as the critical boundary between field device contacts and the controller logic. As a QCI (Contact Closure Input) card designated 6QCI1, it mounts in standard Q-Line I/O chassis and communicates via the proprietary Q-Line parallel bus to deliver digital status information from limit switches, pressure switches, relay contacts, and auxiliary device status inputs to the main control processor.

This module occupies a specialized position in legacy power generation control systems, particularly within turbine generator supervisory and protection schemes developed during the 1980s and 1990s. Unlike voltage-sensing discrete input cards that require powered field devices, the QCI architecture is optimized for dry contact monitoring, providing the excitation voltage necessary to sense contact closures while maintaining complete electrical isolation between field wiring and sensitive controller electronics.

Core Functionality and Signal Handling

The card provides sixteen independent isolated input channels, each capable of sensing dry contact closures from field devices such as turbine limit switches, boiler pressure switches, breaker auxiliary contacts, and safety interlock relays. Each channel features individual galvanic isolation rated to withstand 600V AC potential between the field terminal and the internal backplane circuitry—a critical safety feature when monitoring devices located in high-voltage switchgear compartments or turbine auxiliary cabinets subject to ground potential rise during fault conditions.

The 3A99160G02 sources excitation voltage to the field contacts and senses the returned current upon contact closure, converting the mechanical switch states into digital data packets transmitted across the Q-Line bus. Individual channel LEDs on the card face provide immediate visual indication of input state, enabling technicians to verify field wiring integrity and device status without requiring software interrogation or portable test equipment during maintenance outages.

Platform Heritage and Operational Benefits

As a component of the Westinghouse Q-Line I/O family—the direct predecessor to the modern Ovation distributed control system—the 3A99160G02 reflects the ruggedized design philosophy developed for mission-critical turbine control and power generation applications. The card is functionally equivalent to the 7379A06G02, providing spare parts continuity for legacy installations while maintaining the high reliability standards required for continuous-duty power plant operation.

The contact closure input architecture eliminates the need for external power supplies to excite field contacts, simplifying wiring in remote field cabinets and reducing installation costs. This design proves particularly advantageous in turbine supervisory instrumentation (TSI) applications where proximity probe monitors, vibration sensors, and overspeed protection devices provide dry contact outputs for alarm and trip functions. The high-voltage isolation ensures that ground faults or insulation failures in field wiring cannot propagate to damage the expensive control processor or create safety hazards for maintenance personnel.

3A99160G02

Part 4: Technical Specifications

-

Model Number: 3A99160G02

-

Alternate Part Number: 7379A06G02

-

Manufacturer: Westinghouse Electric Corporation (Process Control Division)

-

Product Type: Q-Line Contact Closure Input Card (QCI)

-

Q-Line Designation: 6QCI1 (QCI G02 Series)

-

Number of Channels: 16 isolated contact closure inputs

-

Input Type: Dry contact (Form A) closure sensing

-

Excitation Voltage: Internal sourcing for contact loop

-

Isolation Rating: 600V AC withstand (channel-to-ground and channel-to-channel), one minute duration

-

Input Impedance: High-impedance sensing circuit compatible with dry contacts

-

Status Indication: Individual LED per channel (front panel)

-

Backplane Interface: Q-Line proprietary parallel bus (Q-rack compatible)

-

Response Time: Typical 5-10ms contact closure detection

-

Power Consumption: Less than 5W (typical)

-

Operating Temperature: 0°C to 60°C (32°F to 140°F)

-

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

-

Humidity: 0% to 95% RH (non-condensing)

-

Mounting: Plug-in card for Q-Line I/O chassis

-

Dimensions: 33.5 cm × 21 cm × 2 cm (PCB assembly)

-

Weight: 0.28 kg (0.62 lbs)

-

Certifications: CE Mark compliant

Part 5: Core Features & Customer Value

Dry Contact Input Optimization: Unlike voltage-sensing input modules that require powered field devices, the QCI architecture provides internal excitation for dry contact loops. For plant engineers, this eliminates the need for separate field power supplies in remote junction boxes, reduces wiring complexity, and ensures reliable sensing of mechanical switch contacts in safety-critical applications such as turbine overspeed trip systems and boiler flame scanner interlocks.

High-Voltage Isolation and Safety: Each input channel maintains 600V isolation from neighboring channels and from the controller logic ground, preventing ground loop currents that can cause erratic logic behavior or damage sensitive electronics. In power generation environments where large ground potential differences exist between switchyard equipment and control room electronics, this isolation ensures reliable sensing of auxiliary contact status without introducing noise or safety hazards into the control system backplane.

Immediate Visual Diagnostics: Individual LED indicators for each input channel enable rapid troubleshooting without requiring engineering workstation access or specialized diagnostic software. Technicians performing field checkout or investigating alarm conditions can verify input states directly at the card face, significantly reducing mean time to repair (MTTR) during maintenance outages and eliminating the need for portable test equipment in energized panels.

Legacy System Continuity: As original Q-Line components are no longer in production, the 3A99160G02 (and its alternate 7379A06G02) provides critical sparing for mature turbine control and boiler management systems. This availability ensures that unplanned card failures do not force emergency shutdowns or premature total system migrations, allowing capital improvement planning on scheduled outage cycles rather than reactive maintenance bases.

Environmental Ruggedness: Built to withstand the electrical noise, vibration, and thermal stresses characteristic of turbine hall and auxiliary equipment room environments, the PCB assembly utilizes industrial-grade components with extended temperature ratings. This construction minimizes intermittent failures caused by temperature cycling or electromagnetic interference from large rotating machinery.

3A99160G02

Part 6: Typical Applications

Turbine Generator Supervisory Systems: The 3A99160G02 is extensively utilized in legacy Westinghouse turbine control systems to monitor the status of protective relays, limit switches, and safety interlocks. In hydrogen-cooled generator installations, the card senses contact closures from stator ground fault relays, differential protection schemes, bearing vibration trip circuits, and seal oil system pressure switches, providing the control system with immediate indication of protective device status.

Boiler Burner Management Discrete Inputs: Within fossil fuel power plant combustion control systems, this module monitors dry contacts from flame scanner safety relays, fuel valve limit switches, and draft fan interlocks in burner front cabinets. The contact closure input capability interfaces directly with the mechanical safety switches required for burner light-off permissives and fuel safety interlocks without requiring external power supplies in the hazardous boiler front environment.

Turbine Supervisory Instrumentation (TSI) Integration: In legacy TSI systems employing contact-closure outputs for vibration, eccentricity, and keyphasor monitoring, the card accepts alarm and trip contacts from proximity probe monitors and shaft-riding position sensors. The high-speed input response characteristics support the rapid protection requirements of overspeed detection and thrust bearing wear monitoring systems, while the isolation prevents ground faults in probe wiring from affecting the DCS backplane.

Switchyard Auxiliary Control: The module finds application in remote Q-Line termination cabinets located in 480V motor control centers (MCCs) and switchgear lineups, where it monitors the dry contacts of breaker auxiliaries, ground fault relays, and interlocking schemes. The 600V isolation rating provides necessary protection for the control system when monitoring devices located in high-voltage environments subject to switching transients and ground potential rise during fault conditions.

Emergency Shutdown and Safety Systems: In safety instrumented functions requiring hardwired relay logic—such as master fuel trips or turbine emergency stop circuits—the module monitors the contact status of safety relays and master trip solenoids. The electromechanical isolation ensures that faults in the digital control system cannot mask true safety device status, supporting independent protection layer requirements per IEC 61511 standards.