Description

1C31223G01: Product Overview

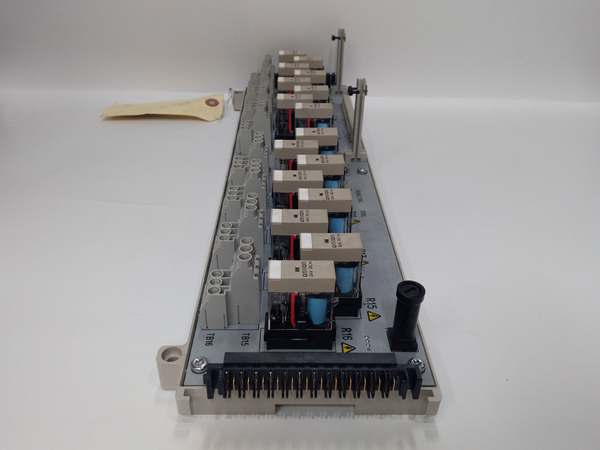

The 1C31223G01 functions as the field interface and relay mounting base for digital output channels within the Westinghouse Ovation Distributed Control System (DCS). In the Ovation I/O architecture, this module represents the physical layer where control logic meets field actuation—providing isolated, high-current switching capability for discrete control signals generated by the Ovation controller.

Positioned within the Ovation I/O subsystem, the 1C31223G01 operates as a companion component to the 1C31219G01 Relay Output Logic Module. The logic module contains the electronics, driver circuits, and communication interface to the Ovation controller’s I/O bus, while the 1C31223G01 provides the actual relay hardware, contact protection, and field termination points. This modular separation allows for flexible maintenance strategies: the logic module can be serviced without disturbing field wiring, and individual relays can be replaced in the base assembly without affecting the control electronics.

The module houses sixteen individual electromechanical relays arranged in a high-density configuration. Each relay provides a Form C (single-pole, double-throw) contact arrangement, giving engineers flexibility to configure outputs as normally open, normally closed, or both for each channel. The G2R-style relays employed in this base are industrial-grade components selected for their balance of switching capacity, physical compactness, and proven reliability in continuous-duty applications. With a contact rating of 5 amperes at 250 VAC or 30 VDC, the module handles the majority of discrete loads encountered in process control: solenoid valves, motor starters, indicator lamps, annunciator horns, and auxiliary relay coils.

As part of the Ovation platform, the 1C31223G01 integrates seamlessly with the system’s deterministic I/O scanning and diagnostic capabilities. The companion logic module continuously monitors relay driver status and communicates channel health back to the Ovation Workstation, enabling operators to identify field circuit faults, blown fuses, or relay coil failures from the control room. This diagnostic visibility reduces the need for field troubleshooting with multimeters during initial commissioning and subsequent maintenance activities.

1C31223G01

1C31223G01: Technical Specifications

-

Model Number: 1C31223G01

-

Manufacturer: Westinghouse Electric Corporation (legacy product, now supported by Emerson Automation Solutions)

-

Product Type: Relay Output Base Assembly (Low Power)

-

System Family: Ovation Expert Control System

-

Number of Channels: 16 relay output channels

-

Relay Type: Electromechanical, G2R style (compact industrial relay)

-

Contact Configuration: Form C (SPDT – Single Pole, Double Throw) per channel

-

Contact Rating: 5 A @ 250 VAC (resistive), 5 A @ 30 VDC (resistive)

-

Maximum Switching Voltage: 250 VAC, 125 VDC

-

Maximum Switching Current: 5 A per channel

-

Minimum Load: 10 mA @ 5 VDC (contact wetting current)

-

Relay Coil Voltage: 24 VDC (driven by companion logic module)

-

Relay Life Expectancy: Minimum 100,000 operations at rated load (mechanical life: 20 million operations)

-

Operate/Release Time: Approximately 15 ms operate, 10 ms release

-

Companion Electronics Module: 1C31219G01 (Relay Output Logic Module) – required for operation

-

Field Terminations: Screw terminals for each relay contact (COM, NO, NC)

-

Fusing: Individual channel fuses typically located on personality module or logic module (check specific system configuration)

-

Isolation: Channel-to-channel isolation via separate relays; field-to-system isolation via relay contacts

-

Indicators: Relay status LEDs typically visible through module faceplate (driven by logic module)

-

Mounting: Plugs into standard Ovation I/O carrier/backplane

-

Operating Temperature: -20°C to +60°C (-4°F to +140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to +185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions: Approximately 12.7 cm x 6.2 cm x 16.2 cm (5.0″ x 2.4″ x 6.4″)

-

Weight: Approximately 0.34 kg (0.75 lbs)

-

Certifications: UL, CE, CSA (typical for Ovation I/O modules)

Core Features & Customer Value

High-Density Relay Switching with Flexible Contact Configuration: The sixteen Form C relays provide substantial discrete output capacity in a single I/O slot, optimizing cabinet space and reducing per-point hardware costs. The SPDT contact arrangement offers engineering flexibility that simpler Form A (NO only) outputs cannot match—each channel can be wired as normally open for standard energize-to-run applications, normally closed for fail-safe de-energize-to-trip configurations, or both for complex interlocking schemes. This flexibility proves valuable in retrofit projects where existing field devices expect specific contact behavior, eliminating the need for external interposing relays.

Proven G2R Relay Technology for General-Purpose Loads: The module utilizes Omron G2R-series or equivalent industrial relays, a technology platform with decades of field-proven reliability in PLC and DCS applications. These sealed relays offer excellent resistance to dust and industrial contaminants while providing consistent contact pressure for reliable low-level switching. For maintenance teams, the widespread availability of G2R relay sockets and replacement relays means procurement lead times are minimal compared to proprietary relay assemblies. The 5-ampere rating handles typical control loads—solenoid valves, contactor coils, and indicator lamps—without requiring external interposing relays, simplifying panel wiring and reducing failure points.

Modular Separation of Logic and Field Interface: The two-piece design separating the 1C31219G01 logic module from the 1C31223G01 relay base provides distinct maintenance advantages. Control logic and communication electronics remain protected in the logic module, while the relay base handles the electrically noisy, high-current field side. If a relay contact welds due to overload or inductive spike, the base can be replaced without discarding expensive electronics. Conversely, if communication diagnostics indicate a driver failure, the logic module swaps without disturbing field terminations. This separation reduces spare parts inventory costs and allows faster mean-time-to-repair (MTTR) during outages.

Integrated Diagnostic Feedback: Through the companion logic module, each relay output channel reports status back to the Ovation controller. This feedback loop allows control strategies to verify that a command to energize a solenoid valve actually resulted in relay closure, enabling alarm generation for failed outputs. During commissioning, engineers can force outputs from the operator workstation and observe relay actuation via the module’s status LEDs, streamlining loop checking without requiring manual jumper wires at the terminal blocks.

Typical Applications

Power Plant Auxiliary Systems Control: In coal-fired, combined-cycle, and nuclear power plants utilizing Ovation DCS platforms, the 1C31223G01 commonly controls auxiliary equipment throughout the balance-of-plant. Typical applications include energizing solenoid valves for cooling water systems, controlling lube oil pump motor contactors, and driving annunciator horns for operator alerts. The 250 VAC rating accommodates the 120 VAC and 240 VAC control circuits prevalent in North American power generation facilities, while the Form C contacts provide flexibility for both energize-to-run and fail-safe de-energize configurations required by plant safety analyses.

Water and Wastewater Treatment Plant Discrete Control: Municipal water treatment facilities employing Ovation systems for process automation frequently deploy this module for pump control, valve actuation, and chemical feed system enable signals. In filter backwash sequences, the module controls the multiple solenoid valves that direct flow through different filter cells. The 5-ampere contact rating directly drives valve solenoids without interposing relays, reducing panel complexity. The sealed G2R relays withstand the humid, corrosive atmospheres common in wastewater applications better than open-frame relay alternatives.

Petrochemical Process Unit Interlocking: In refineries and chemical plants with legacy Ovation installations, the 1C31223G01 implements safety interlocks and permissive logic for rotating equipment and heat exchangers. The module drives the final control elements—motor starter coils, solenoid-operated block valves, and pilot lights—that execute interlock actions. Engineers often utilize the Form C contacts to create hardwired bypass circuits or to provide both control room indication and field device actuation from a single output channel, reducing the total I/O count required for complex interlocking schemes.

Pulp and Paper Machine Control: Paper mills utilizing Ovation DCS for machine control deploy this module for machine direction and cross-direction control elements. Applications include controlling steam valve solenoids for dryer section temperature zones, energizing hydraulic pump motors for calendar stack loading, and driving warning beacons for thread-up sequences. The module’s ability to switch 125 VDC circuits (common in older paper machine DC drive contactor coils) makes it suitable for facilities with mixed-voltage control architectures.