Description

System Role and Integration

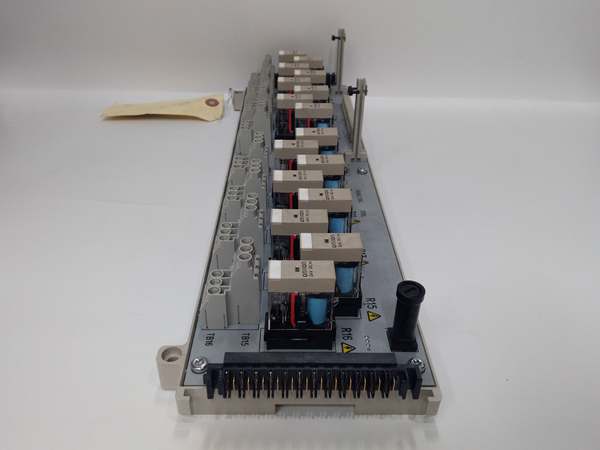

The 1C31223G01 serves as the electromechanical switching foundation within the Ovation Distributed Control System architecture, functioning as the Relay Output Base Assembly that interfaces between the controller logic and high-power field devices. As a G2R-style relay base, it mounts in standard Ovation I/O racks and works in conjunction with the 1C31219G01 Relay Output Electronics Module to provide discrete control of motors, solenoids, heaters, and alarm annunciators.

This module occupies a critical position in the Ovation output hierarchy, specifically designated as the “Low Power” relay base alternative to the KUEP-style 1C31222G01. While the 1C31222G01 handles higher DC voltages and currents using KUEP relays, the 1C31223G01 utilizes G2R electromechanical relays optimized for standard industrial loads up to 10A. This distinction allows system engineers to select the appropriate relay technology based on specific load requirements—specifying the G01 for general-purpose AC and moderate DC switching while reserving the KUEP variant for heavy-duty DC applications.

Core Functionality and Signal Handling

The base assembly houses sixteen G2R electromechanical relays, each configured with Form C (single-pole double-throw) contacts that provide normally open and normally closed switching options. The relays are energized by the 1C31219G01 Electronics Module, which plugs into the base and provides the low-voltage coil drive signals, blown fuse detection, and diagnostic feedback to the Ovation controller.

Each relay contact is rated for 10 amps at 250 volts AC (power factor = 1) or 10 amps at 30 volts DC, accommodating standard industrial loads such as motor contactor coils, solenoid valves, and indicating lamps. The Form C configuration allows flexible wiring for either fail-safe (de-energize to trip) or fail-last control strategies depending on application requirements.

Critical to safe operation, the module provides 2300V AC/DC dielectric isolation between the relay contacts and the logic circuitry, ensuring that high-voltage field faults cannot propagate to the sensitive controller electronics. The base assembly does not incorporate a personality module—instead, the 1C31219G01 Electronics Module plugs directly into the base to complete the functional assembly.

Platform Heritage and Operational Benefits

As a component of the Westinghouse Ovation platform now maintained within Emerson’s automation portfolio, the 1C31223G01 reflects the ruggedized relay technology developed for continuous-duty industrial applications. The G2R relay technology utilized in this base provides proven reliability for general-purpose switching, with operate times of approximately 15 milliseconds and release times of 10 milliseconds—sufficient for most process control applications without requiring the heavy-duty capacity of KUEP relays.

The modular design allows hot replacement of the electronics module (1C31219G01) without disturbing field wiring, while the base itself mounts securely in Ovation I/O racks with standard mechanical retention. Integration with Ovation auxiliary power supplies provides the 24VDC relay coil excitation, eliminating the need for external relay power supplies and ensuring consistent voltage levels across all outputs.

WESTINGHOUSE 1C31223G01

Part 4: Technical Specifications

-

Model Number: 1C31223G01

-

Manufacturer: Westinghouse Electric Corporation (Emerson Ovation product line)

-

Product Type: Relay Output Base Assembly (G2R Style)

-

Number of Channels: 16 relay outputs

-

Relay Type: G2R electromechanical, Form C (SPDT) contact arrangement

-

Contact Ratings:

-

10 amps @ 250 VAC, PF = 1

-

10 amps @ 30 VDC

-

-

Dielectric Isolation: 2300V AC/DC (relay contacts to logic)

-

Compatible Electronics Module: 1C31219G01 (Relay Output EMOD)

-

Personality Module: Not required (direct EMOD interface)

-

Relay Timing:

-

Operate time: 15 mSec (bounce approximately 3 mSec)

-

Release time: 10 mSec (bounce approximately 8 mSec)

-

-

Blown Fuse Detection: Configurable via 1C31219G01 electronics

-

Power Supply: 24VDC auxiliary (from Ovation backplane, recommended)

-

Base Power Consumption: 9.1W typical, 11.68W maximum (all relays energized)

-

Operating Temperature: 0°C to 60°C (32°F to 140°F)

-

Storage Temperature: -40°C to 70°C (-40°F to 158°F)

-

Humidity: 35% to 85% RH (non-condensing)

-

Mounting: Standard Ovation I/O base assembly (ROP panel compatible)

-

Dimensions: 16 cm × 16 cm × 12 cm (6.3 in × 6.3 in × 4.7 in) typical

-

Weight: 0.8 kg to 2.45 kg (1.8 lbs to 5.4 lbs) depending on packaging

-

Fuse Rating: 5x20mm cartridge, 1.0A, 250V fast acting (Part Number EX06104)

-

Certifications: CE Mark certified (all configurations)

Part 5: Core Features & Customer Value

Sixteen-Channel High-Density Switching: The 16-relay configuration maximizes control output density within standard Ovation enclosures, reducing per-point hardware costs compared to lower-density alternatives. For facilities requiring extensive discrete control—such as boiler burner management systems or water treatment valve manifolds—this density allows comprehensive control without excessive cabinet proliferation.

Form C Contact Flexibility: The SPDT (single-pole double-throw) contact configuration provides both normally open and normally closed circuits for each relay, enabling flexible control strategies. Engineers can implement fail-safe de-energize-to-trip logic for safety interlocks or maintain-last-state functionality for process valves, adapting the same hardware to diverse application requirements without additional external relays.

High Dielectric Isolation: The 2300V isolation rating between field contacts and controller logic provides robust protection against ground faults and high-voltage transients. In power plant switchyard environments and heavy industrial facilities where large ground potential differences exist between control rooms and field equipment, this isolation ensures reliable operation while protecting sensitive microprocessor-based controllers from damaging voltage spikes.

Direct EMOD Interface Without PMOD: Unlike many Ovation I/O modules requiring personality modules, the 1C31223G01 interfaces directly with the 1C31219G01 Electronics Module. This simplification reduces spare parts inventory complexity—technicians stock the base and electronics module without tracking multiple personality module variants—and eliminates potential mismatches during maintenance activities.

Blown Fuse Detection Capability: When paired with the 1C31219G01 electronics, the base supports configurable blown fuse detection for each relay channel. This diagnostic capability alerts operators to open-circuit conditions caused by overcurrent events, enabling proactive maintenance before control functionality is lost and reducing the risk of undetected field wiring failures.

WESTINGHOUSE 1C31223G01

Part 6: Typical Applications

Power Plant Auxiliary Control: The 1C31223G01 is extensively deployed in coal-fired, gas-fired, and nuclear generating stations for control of boiler auxiliary equipment, turbine lube oil systems, and cooling water pumps. In these applications, the 10A @ 250VAC rating accommodates standard motor contactor coils and solenoid valves, while the G2R relays provide economical switching for general-purpose loads that do not require the heavy-duty DC capacity of KUEP relays.

Water Treatment Valve Manifolds: Municipal and industrial water treatment facilities utilize the module to control backwash valve sequences, chemical feed pumps, and transfer pump motor starters. The 16-channel density supports the numerous discrete outputs required for filter backwash sequences and chemical dosing systems, while the Form C contacts allow flexible wiring for both pump start/stop circuits and valve open/close interlocks.

Manufacturing and Process Industries: General manufacturing facilities employ the module for machine control, conveyor system motor starters, and auxiliary equipment switching. The 30VDC rating accommodates standard 24VDC control circuits common in modern manufacturing equipment, while the 250VAC capability supports legacy 120VAC and 240VAC load requirements without requiring separate relay hardware.

Building Automation and HVAC: Commercial and institutional facilities integrate the module into building management systems for control of fans, dampers, and pumps. The electromechanical relays provide positive visual indication of contact status during maintenance activities, while the high isolation protects building automation controllers from ground faults in large mechanical equipment.

Safety Instrumented System (SIS) Interfacing: While not safety-rated itself, the module provides the final output element for safety instrumented functions requiring hardwired relay logic. In combination with safety logic solvers, the Form C contacts support de-energize-to-trip architectures for emergency shutdown valves and fuel master trip relays, with the electromechanical construction providing visual confirmation of safety system status during testing.