Description

System Role and Integration

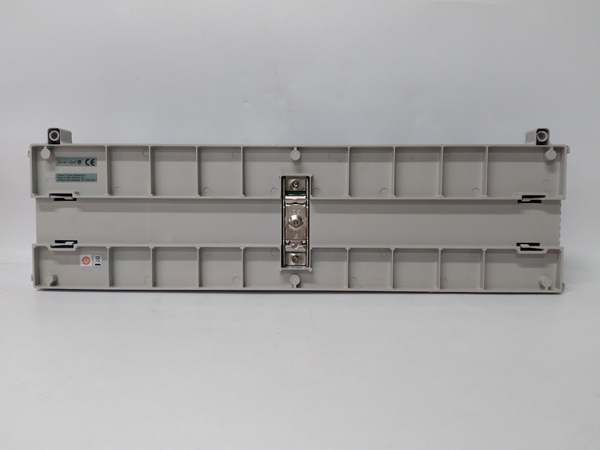

The 1C31222G01 serves as a foundational electromechanical interface within the Ovation Distributed Control System architecture, specifically engineered for applications requiring robust isolation and high-current switching capability. As a relay output base module, it occupies a critical position in the I/O hierarchy, bridging the gap between the controller’s low-voltage logic signals and field devices operating at higher power levels. This unit mounts within standard Ovation I/O carriers and operates in conjunction with corresponding electronic personality modules to deliver discrete switching control to motors, solenoids, heaters, and alarm annunciators in power generation and heavy process environments.

Core Functionality and Signal Handling

This module houses twelve KUEP-style electromechanical relays, factory-configured at the project level to utilize either Form C (single-pole double-throw) or Form X contact arrangements depending on specific load requirements. Unlike solid-state alternatives, the 1C31222G01 provides true galvanic isolation between the Ovation controller backplane and field wiring, mitigating ground loop issues and providing high immunity to electrical noise prevalent in switchyard and turbine hall environments.

The module handles the physical switching of AC and DC loads at current levels exceeding those supported by the companion G2R-style base (1C31223G01), making it particularly suitable for high-inrush current applications and DC voltage switching scenarios common in legacy power plant auxiliary systems. Critical to safe operation, the module architecture requires the application engineer to design external current limiting protection into each circuit to prevent contact damage during overload conditions.

Platform Heritage and Operational Benefits

As a component of the Westinghouse Ovation platform—now maintained within the Emerson portfolio—this module benefits from decades of field deployment in mission-critical power generation facilities. The Ovation I/O family employs a modular design philosophy allowing hot-replacement of base modules and electronic subassemblies, minimizing mean time to repair (MTTR) during unplanned maintenance events. The KUEP relay technology utilized in this specific model offers enhanced contact materials and mechanical robustness compared to general-purpose relays, delivering extended mechanical life in continuous-duty applications. Integration with the Ovation controller node provides seamless diagnostic visibility, allowing operators to monitor relay command states while maintaining hardwired safety interlocks independent of the digital control network.

1C31222G01

Part 4: Technical Specifications

-

Model Number: 1C31222G01

-

Manufacturer: Westinghouse Electric Corporation (Ovation product line)

-

Product Type: Relay Output Base Module

-

Relay Technology: KUEP-style electromechanical relays

-

Number of Channels: 12 discrete relay outputs

-

Contact Configuration: Form C (SPDT) or Form X, project-configurable

-

Switching Capacity: High AC/DC voltage and current capability (exceeds G2R ratings)

-

Isolation: Electromechanical isolation between field terminals and logic backplane

-

Protection Requirements: External current limiting protection mandatory per channel

-

Mounting: Ovation-compatible I/O carrier/base assembly

-

Operating Temperature: 0°C to 60°C (standard Ovation I/O environmental range)

-

Storage Temperature: -40°C to 85°C

-

Humidity: 0% to 95% RH (non-condensing)

-

Dimensions: Approximately 16 cm × 16 cm × 12 cm

-

Weight: Approximately 0.8 kg

Part 5: Core Features & Customer Value

High-Capacity Load Switching: The KUEP relay configuration distinguishes this module from the standard G2R variant (1C31223G01) through significantly enhanced current-carrying capacity and the ability to switch higher DC voltages safely. For facility engineers, this translates to the ability to control larger auxiliary loads—such as motor contactors, large solenoid valves, and power distribution relays—directly from the DCS without intermediate interposing relays, reducing panel complexity and potential failure points.

Configurable Contact Arrangements: The module’s project-level configuration as either Form C or Form X accommodates diverse control strategies. Form C provides versatile SPDT switching suitable for fail-safe or fail-last control schemes, while Form X configurations address specific safety or latching requirements. This flexibility allows procurement standardization across multiple plant areas while maintaining application-specific functionality.

Galvanic Isolation and Noise Immunity: Unlike solid-state output modules, the electromechanical construction provides absolute isolation between the sensitive Ovation controller electronics and harsh field environments. In high-voltage switchyard applications or near large VFD installations, this isolation prevents ground potential differences from damaging expensive controller assets and eliminates common-mode noise issues that can plague transistorized outputs.

Safety-Centric Design Requirements: The mandatory requirement for external current limiting protection, while adding engineering complexity, ensures that application-specific fault currents are calculated and mitigated at the design stage. This approach prevents catastrophic relay welding during short-circuit events and aligns with power generation industry standards for protective relaying circuits.

Part 6: Typical Applications

Fossil Fuel Power Generation: The 1C31222G01 is frequently deployed in coal-fired and oil-fired generating stations for control of boiler auxiliary equipment. In forced-draft and induced-draft fan motor control circuits, the module’s high-current capacity allows direct switching of contactor coils while providing the robust isolation necessary to protect DCS electronics from motor starting transients and ground faults common in 480V MCC environments.

Combined Cycle Turbine Control: Within combined-cycle power blocks, this module manages critical fuel oil forwarding pump controls and cooling water valve solenoids. The ability to switch higher DC voltages proves essential in older turbine auxiliary systems operating at 125VDC, where standard relay bases would experience contact degradation or welding under high inductive loads.

Emergency Shutdown and Safety Systems: In safety instrumented functions (SIF) requiring hardwired relay logic—such as turbine overspeed protection trips or boiler fuel master shutdown sequences—the module’s Form X configuration capabilities support fail-safe de-energize-to-trip architectures. The electromechanical relays provide positive visual indication of contact state during safety system testing, unlike solid-state alternatives where fault states may be less apparent to maintenance technicians.

Water Treatment and Auxiliary Systems: The module finds application in demineralizer backwash valve manifolds and chemical feed pump controls, where the high contact rating accommodates the inrush currents of larger diaphragm valves and metering pumps without requiring additional interposing relay hardware.