Description

Product Overview

The GE SR750 – P1 – G1 – S1 – HI – A20 – G is a high – performance motor protection relay from GE Multilin’s 239 motor protection relay family. It is engineered to offer comprehensive protection for three – phase AC motors in harsh industrial settings. This relay is a crucial component in industrial automation systems, safeguarding motors from various faults. With functions like circuit breaker failure protection, overload warning, ground fault protection, and lock – turn protection, it ensures the reliable operation of motors. The SR750 – P1 – G1 – S1 – HI – A20 – G features a clear front – facing LCD display. This allows operators to easily monitor important parameters such as motor status, temperature, and current. It also supports multiple communication protocols, making it highly adaptable to different industrial network setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SR750 – P1 – G1 – S1 – HI – A20 – G |

| Manufacturer | GE |

| Product Type | Motor Protection Relay |

| Input Voltage | 750/760 V |

| Frequency | 50/60 Hz |

| Rated Current | Depends on application |

| Communication Protocol | Modbus ® RTU, DNP 3.0 level 2, Modbus RTU TCP/IP |

| Display | Front – facing LCD |

| Certification | CSA, UL |

| Operating Temperature | – 40 °C to 70 °C |

| Mounting Method | DIN – rail or panel – mountable |

| Number of Serial Ports | 3 (1 RS232 on front, 2 RS485/RS422 on rear) |

| Optional Ethernet Port | Available |

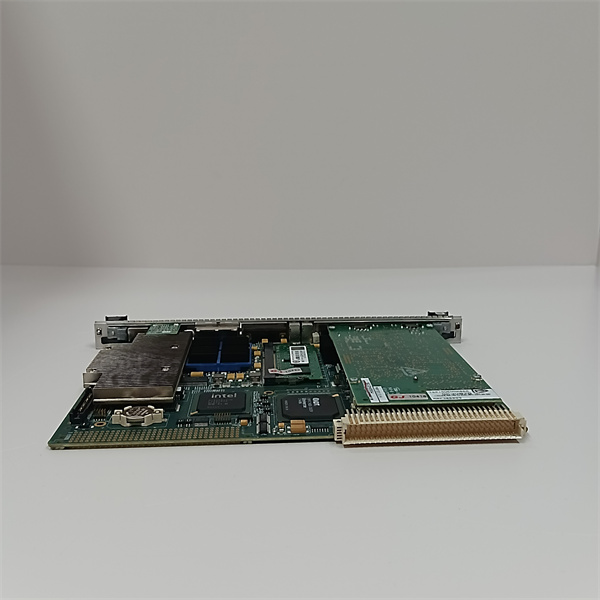

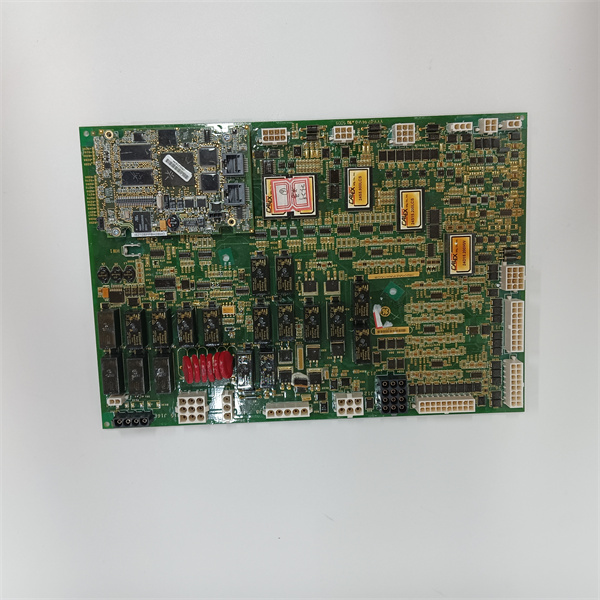

VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J

Main Features and Advantages

Comprehensive Protection

The GE SR750 – P1 – G1 – S1 – HI – A20 – G offers a wide array of protection functions. Its circuit breaker failure protection can quickly detect and respond when a breaker fails to operate as expected, preventing potential disasters. Overload warning protection gives early alerts when the motor is approaching an overloaded state, allowing for timely intervention to avoid damage. Ground fault protection safeguards against faults between the motor windings and the ground, while lock – turn protection prevents damage when the motor is blocked from rotating.

User – Friendly Interface

Equipped with a front – facing LCD display, this relay provides easy – to – read information about motor status, temperature, and current. Operators can quickly assess the motor’s condition and make informed decisions. The display is designed to be clear and intuitive, reducing the learning curve for new users.

Flexible Communication

With support for Modbus ® RTU, DNP 3.0 level 2, and Modbus RTU TCP/IP protocols, the SR750 – P1 – G1 – S1 – HI – A20 – G can seamlessly integrate into different industrial automation networks. It has three standard serial communication ports and an optional rear – panel Ethernet port, enabling both local and remote communication. This flexibility allows for easy connection to DCS, SCADA, or PLC systems.

High – Quality Certification

Being CSA and UL certified, the GE SR750 – P1 – G1 – S1 – HI – A20 – G meets strict safety and quality standards. These certifications ensure that the relay can be safely used in a wide range of industrial applications, giving users peace of mind.

IS200AEPAH1ACB

Application Field

In the manufacturing industry, the GE SR750 – P1 – G1 – S1 – HI – A20 – G is extensively used to protect motors in production lines. For example, in automotive manufacturing plants, it guards the motors that power robotic arms, conveyor belts, and other machinery. By preventing motor failures, it helps maintain the smooth operation of the production process and reduces downtime.

In the power industry, this relay is crucial for protecting motors in power generation equipment, substations, and distribution systems. It ensures that motors in generators, pumps, and fans operate safely and efficiently, contributing to stable power supply.

The oil and gas industry also relies on the SR750 – P1 – G1 – S1 – HI – A20 – G to protect motors in pumps, compressors, and other critical equipment. In such harsh environments, the relay’s ability to withstand extreme conditions and provide reliable protection is highly valued.

In water and wastewater treatment plants, the relay is used to safeguard motors in pumps and blowers. This helps ensure the continuous operation of the treatment processes, which are essential for maintaining clean water supplies and proper wastewater disposal.

Related Products

- 489 – P1 – LO – A20: A motor management relay basic unit with a 1 A phase CT secondary and 20 – 60 VDC, 20 – 48 VAC at 48 – 62 Hz. It has basic display capabilities and is suitable for applications with lower – level monitoring requirements compared to the SR750 – P1 – G1 – S1 – HI – A20 – G.

- 489 – P1 – LO – A20 – E: Similar to the 489 – P1 – LO – A20, but with enhanced display capabilities. It offers more detailed information, making it useful for applications where better visualization of motor parameters is needed.

- 489 – P5 – HI – A20: A series 489 motor management relay with a basic display and high – control power supply. It has different power and display characteristics compared to the SR750 – P1 – G1 – S1 – HI – A20 – G, catering to specific power – intensive applications.

- 489 – P5 – HI – A20 – E: Operates at 90 – 300 VDC, 70 – 265 VAC, 48 – 62 Hz, and has an enhanced display. This product is designed for applications with specific voltage requirements and a need for detailed parameter visualization.

- 489 – P5 – HI – A20 – EH: Features an enhanced display screen, larger LCD, and conformal coating for harsh environments. It is more suitable for extremely harsh industrial settings compared to the SR750 – P1 – G1 – S1 – HI – A20 – G, where extra protection against environmental factors is crucial.

Installation and Maintenance

Pre – installation preparation: Before installing the GE SR750 – P1 – G1 – S1 – HI – A20 – G, ensure that the installation environment meets the temperature and humidity requirements specified in the product manual. Check the power supply voltage to confirm it matches the relay’s input voltage range. Mount the relay securely using either the DIN – rail or panel – mount method as instructed. Make sure to connect all communication and power cables correctly, following the wiring diagrams provided.

Maintenance recommendations: Regularly clean the surface of the SR750 – P1 – G1 – S1 – HI – A20 – G to remove dust and dirt, which can affect its performance. Check the connection terminals for any signs of looseness or corrosion. Monitor the operating status through the LCD display and look for any abnormal indications. If any issues are detected, refer to the user manual for troubleshooting steps. Periodically update the relay’s firmware to benefit from the latest features and improvements.

Product Guarantee

GE stands firmly behind the quality of the SR750 – P1 – G1 – S1 – HI – A20 – G. The company ensures that the product is manufactured to the highest standards, with strict quality control measures in place. There is a one – year warranty from the date of purchase. In case of any quality issues within this period, GE will provide free repair or replacement services. Their technical support team is available around the clock to offer assistance. Whether it’s help with installation, operation, or troubleshooting, customers can rely on GE’s expertise. This demonstrates GE’s confidence in the product’s reliability and their commitment to customer satisfaction.