Description

Product Overview

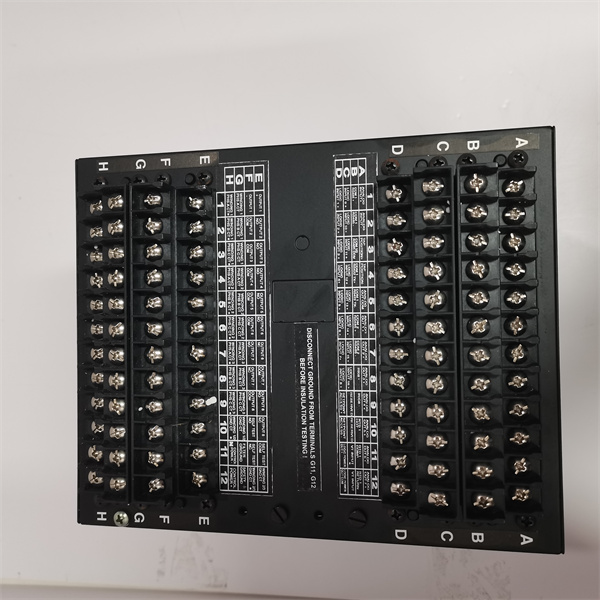

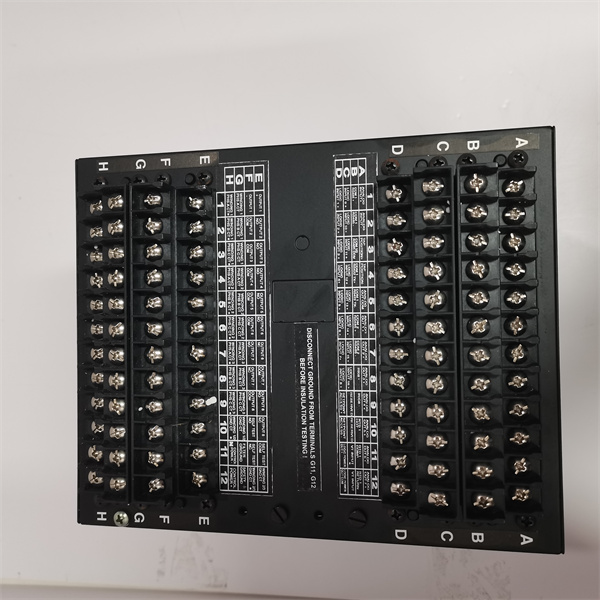

The GE SR745 – W2 – P1 – G1 – HI – E – H is a state – of – the – art transformer management system developed by General Electric. It serves as a comprehensive solution for safeguarding and efficiently managing transformers, autotransformers, and reactors. This system is part of GE’s reliable product line, designed to meet the stringent demands of industrial control applications.

The GE SR745 – W2 – P1 – G1 – HI – E – H offers a wide array of core functions. It provides multiple protection functions, such as overcurrent, overvoltage, undervoltage, differential, and frequency protection. This ensures that transformers are shielded from various fault scenarios, guaranteeing their safe and stable operation. The enhanced 40 – character display and expanded keypad simplify the manual entry of setpoints, making it user – friendly for operators. It also features advanced RTD capabilities for precise temperature monitoring, enhancing the overall operational efficiency and safety. In the industrial automation system, the GE SR745 – W2 – P1 – G1 – HI – E – H plays a crucial role in maintaining the integrity of the power infrastructure, contributing to the smooth running of industrial processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SR745 – W2 – P1 – G1 – HI – E – H |

| Manufacturer | General Electric |

| Product Type | Transformer Management System |

| Winding Configuration | 2 windings per phase |

| RTD Type | 3 – wire; 100 ω nickel, 120 ω nickel, 100 ω platinum |

| Analog Output Maximum Load | 10 kω at 0 to 1 ma, 600 ω at 4 to 20 ma |

| Maximum Continuous Voltage Output | 273 V |

| Display Type | 40 – character enhanced LCD |

| Dimensions | 9” h x 7” w x 7 ⅛” d |

| Control Power Range | 90 to 300 V dc; 70 to 265 V ac at 48 to 62 Hz |

| Rated Voltage | 5 kV |

| Rated Current | 2 A |

SR745-W2-P1-G1-HI-E-H

Main Features and Advantages

Comprehensive Protection

The GE SR745 – W2 – P1 – G1 – HI – E – H offers an extensive range of protection functions. Overcurrent protection safeguards equipment from damage due to excessive current, while overvoltage protection shields transformers from high – voltage – induced harm. Undervoltage protection ensures that low voltage does not disrupt normal equipment operation. Differential protection is used to detect internal transformer faults like inter – turn short circuits, and frequency protection keeps the transformer operating within the specified frequency range. This all – round protection coverage is essential for maintaining the long – term health of transformers.

FlexLogic™ Technology

This system adopts FlexLogic™ technology, which, when combined with its set – point capabilities, creates a highly flexible programming structure. This allows the GE SR745 – W2 – P1 – G1 – HI – E – H to be customized to meet the unique requirements of specific systems. Whether it’s a complex industrial power setup or a more straightforward commercial distribution system, the system can be configured to provide optimal protection and management.

User – Friendly Interface

Equipped with an enhanced 40 – character LCD display and an expanded keypad, the GE SR745 – W2 – P1 – G1 – HI – E – H significantly improves input efficiency and readability. Operators can easily view critical information and manually enter setpoints, reducing the likelihood of errors. This user – friendly interface also simplifies the process of parameter setting, fault viewing, and system debugging.

SR745-W2-P1-G1-HI-E-H

Application Field

The GE SR745 – W2 – P1 – G1 – HI – E – H finds extensive use in power systems for transformer protection and management. In industrial settings, such as manufacturing plants, it protects the transformers that power production equipment. By ensuring stable power supply, it prevents production interruptions caused by transformer failures, thus maintaining high productivity.

In commercial buildings, the system safeguards transformers that provide electricity for lighting, air – conditioning, and other electrical systems. This helps to ensure a reliable power supply, enhancing the comfort and functionality of the building.

Power plants and substations also rely heavily on the GE SR745 – W2 – P1 – G1 – HI – E – H. In these large – scale power facilities, it monitors and protects high – voltage transformers. Its accurate protection and management functions are crucial for maintaining the stability and safety of the entire power grid, preventing power outages that could have far – reaching consequences.

Related Products

- GE SR745 – W2 – P1 – G1 – HI – A – L – R – E: Similar to the GE SR745 – W2 – P1 – G1 – HI – E – H, it is a transformer protection relay in the GE Multilin series. However, it may have differences in specific protection settings or additional features tailored for different applications.

- GE 369 – LO – 0 – M – F – E – 0 – 0: A motor management relay. Although it is designed for motors rather than transformers like the GE SR745 – W2 – P1 – G1 – HI – E – H, it is part of GE’s electrical protection product line and may be used in systems where both motor and transformer protection are required.

- GE 369 – HI – R – M – 0 – 0 – 0 – 0: Another motor management relay. It can be used in different motor – related applications and may complement the GE SR745 – W2 – P1 – G1 – HI – E – H in an industrial setup that has both motor – driven and transformer – based equipment.

- GE IS220PRTDH1A: A resistance temperature device (RTD) input module. It can work in tandem with the GE SR745 – W2 – P1 – G1 – HI – E – H to enhance the temperature – monitoring capabilities of the transformer management system, providing more accurate temperature data for better protection.

- GE IS220PDIAH1A: A discrete contact I/O pack. This product can be used to interface with other devices in the control system along with the GE SR745 – W2 – P1 – G1 – HI – E – H, facilitating communication and control between different components in the industrial automation setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE SR745 – W2 – P1 – G1 – HI – E – H, carefully review the installation manual provided by GE. Ensure that the installation environment is clean, dry, and free from excessive vibration and electromagnetic interference. Check the compatibility of the device with the existing power system, including the power supply voltage and frequency. Verify that the 19 – inch panel, if applicable, has the correct dimensions and mounting provisions. Power off all related electrical equipment to prevent electrical shock during installation.

Maintenance recommendations: Regularly inspect the GE SR745 – W2 – P1 – G1 – HI – E – H for any signs of physical damage, such as cracks on the enclosure or loose connections. Clean the device periodically to remove dust and dirt, which can affect its performance. Check the accuracy of the protection functions by performing routine tests. Update the firmware to the latest version provided by GE to benefit from the latest features, bug fixes, and security enhancements. If any issues are detected, refer to the troubleshooting guide in the manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE SR745 – W2 – P1 – G1 – HI – E – H. The product is manufactured using high – quality materials and advanced manufacturing processes, ensuring it meets strict quality standards. GE offers a standard warranty period during which any manufacturing defects will be rectified free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. Whether it’s answering questions about the system’s operation or providing guidance on maintenance, customers can rely on GE’s expertise. This guarantee reflects GE’s confidence in the product and their commitment to providing reliable industrial control solutions, giving customers peace of mind when using the GE SR745 – W2 – P1 – G1 – HI – E – H in their critical applications.