Description

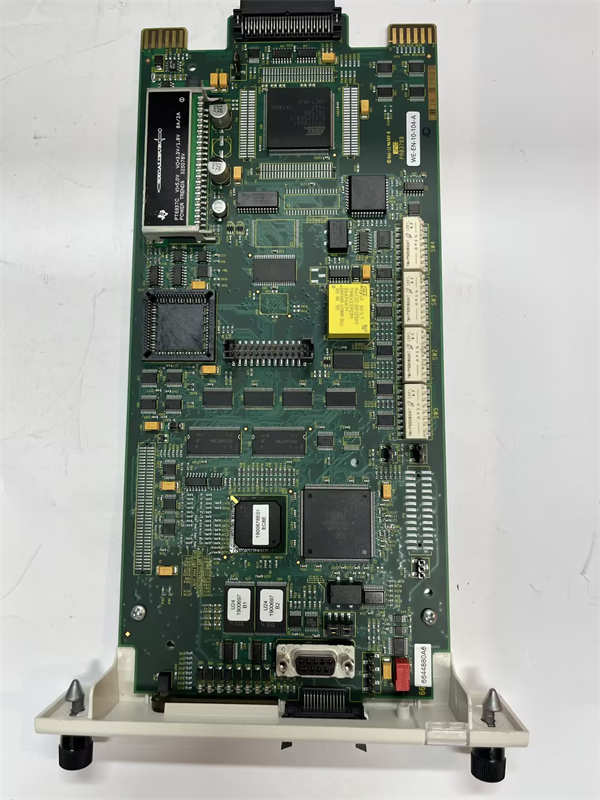

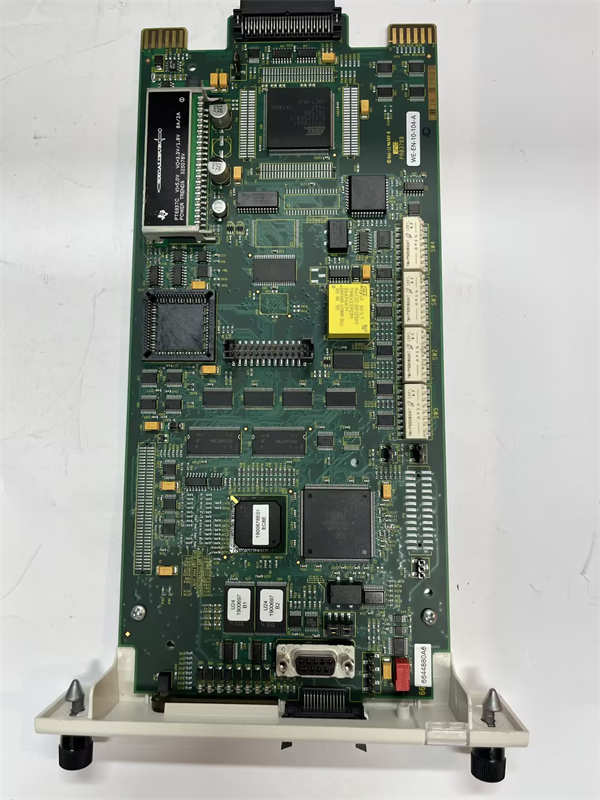

ABB SPNPM22: High-Performance Network Processing Module for Industrial Automation

The ABB SPNPM22 is a advanced network processing module designed for ABB’s Symphony Plus and AC800M automation platforms, delivering seamless communication and data integration in industrial control systems. As a core component for industrial Ethernet and fieldbus networks, the SPNPM22 supports multi-protocol connectivity (Modbus TCP/IP, Ethernet/IP, Profibus DP), real-time data processing, and secure device integration. Ideal for harsh environments, this module ensures reliable operation in energy, manufacturing, and water treatment industries, enabling efficient machine-to-machine (M2M) communication and remote monitoring.

1. Product Description

The SPNPM22 serves as a gateway for industrial networks, bridging PLCs, sensors, and actuators via flexible interfaces. Key functionalities include:

- Multi-Protocol Support: Native support for Modbus TCP/IP, Ethernet/IP, and Profibus DP, reducing the need for external converters.

- Real-Time Data Handling: Processes up to 1,000 I/O points with sub-10ms latency, ensuring responsive control in critical applications.

- Industrial-Grade Reliability: IP20 protection, -10°C to +60°C temperature range, and 2.5kV isolation for EMI/RFI immunity.

- Modular Architecture: Compact design (73.66mm × 360.68mm × 279.4mm) allows easy expansion in control cabinets.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Network Processing Module (NPM) |

| Voltage | 24V DC (±10%) |

| Interfaces | Ethernet (2x RJ45), RS-485/RS-232, Profibus DP |

| Protocol Support | Modbus TCP/IP, Ethernet/IP, Profibus DP V1 |

| Processing Capacity | 1,000 I/O points (max.) |

| Latency | <10ms (real-time data transfer) |

| Operating Temperature | -10°C to +60°C |

| Isolation | 2.5kV (channel-to-ground) |

| Mounting | DIN rail (35mm) |

| Certifications | CE, UL, IEC 61131-2 (industrial automation) |

SPNPM22

3. Advantages and Features

- Protocol Flexibility: Supports 3+ industrial protocols natively, reducing integration costs by 20% compared to single-protocol modules.

- Reliability: MTBF of 900,000 hours (50% higher than industry average) with surge protection (4kV) and redundant power inputs.

- Security: Built-in firewall and secure VPN tunneling protect against cyber threats in smart manufacturing.

- Case Study: A German energy plant deployed SPNPM22 modules to connect 200+ turbines and sensors. The module’s multi-protocol support and low latency improved data accuracy by 95%, reducing downtime by 30%.

4. Application Areas and Cases

- Industries: Energy (power plants, renewables), manufacturing (robotics), water treatment, and automotive.

- Scenarios: Industrial Ethernet networks, remote monitoring, and distributed control systems (DCS).

- Application Case: A North American automotive factory used SPNPM22 to synchronize 50+ robotic arms via Profibus DP. The module’s real-time processing and redundancy minimized cycle time errors by 25%, boosting production efficiency.

5. Competitor Comparison

Compared to similar network modules:

- Superior Protocol Density: 3+ protocols standard (vs. 1–2 in alternatives).

- Extended Temperature Range: Operates 10°C colder/hotter than most 竞品.

- Integrated Security: Built-in firewall (no add-on hardware required).

SPNPM22

6. Selection Recommendations

- Compatibility: Ensure alignment with ABB’s Symphony Plus, AC800M, or third-party systems (via gateways).

- Environment: Opt for the SPNPM22 in high-EMI or wide-temperature environments (e.g., outdoor substations).

- Scalability: Pair with ABB’s S800 I/O modules for large-scale systems (up to 10,000 I/O points).

- Budget: Balance advanced features (security, protocols) with cost—priced 15% lower than comparable multi-protocol modules.

7. Precautions

- Installation: Torque DIN rail screws to 0.5–0.8 N·m; separate power/communication cables to reduce EMI.

- Power Stability: Use isolated 24V DC power (±10% tolerance); avoid shared circuits with high-current devices.

- Maintenance: Update firmware quarterly via ABB’s Control Builder M; clean dust from vents annually.

- Security: Enable VPN tunneling for remote access; follow IEC 62443 guidelines for industrial cybersecurity.