Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | Saia PCD3.M6340 |

| Manufacturer | Saia-Burgess Controls AG |

| Product category | CPU Base Unit |

| Description | PCD3 processor unit with CAN bus interface and Ethernet TCP/IP |

| Operating Voltage | 24 VDC (15 to 30 VDC) |

| Power Consumption | Typically 15 W for 64 I/Os |

| Load-carrying ability 5 V / 24 V internal | Max 600 mA / 100 mA |

| Short Voltage Interruption (according to EN / IEC 61131-2) | ≤ 10 ms with interval ≥ 1 s |

| Watchdog Relay Closing Contact | 48 VAC or VDC, 1 A |

| Storage Temperature | -25°C to +70°C |

| Operating Temperature | 0°C to +55°C (or 0°C to +40°C depending on mounting situation) |

| Relative Humidity | 10% to 95% RH, non-condensing |

| Type of Mounting | Top-hat rail according to DIN EN 60715 TH35 (formerly DIN EN 50022) (1 × 35 mm) |

| Protection Level | IP 20 |

| Flame Resistance | UL 94 V0 |

| Dimensions (L x W x H) | 139 mm x 125.8 mm x 28.5 mm |

| Weight | 580 g |

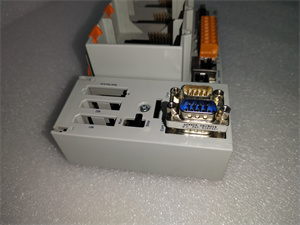

| Communication Interfaces | USB, RS-232, RS-485, CAN (up to 1 MBit/s), Ethernet TCP/IP (10/100 Mbits) |

| Program Memory | 1 MByte user program memory, 1 MByte Flash as backup memory |

| Backup Option | PCD7.R500 Flash card, clock (RTC), data protection for 1-3 years |

| I/O Capacity | Up to 1024 I/O points, 2 interrupts |

| RS-232 Interface | 9-pin D-Sub socket |

| RS-485 Interface | 2x RS-485 for Profi-S-Net/MPI/S-Bus |

| CAN Interface | Galvanic isolated high-speed 1 MBit/s CAN interface |

| Ethernet Interface | 10/100 Mbits, full-duplex, auto-sensing, auto-crossing |

| USB Interface | For PG5 configuration and diagnostics |

| Web Server | Integrated Web server for configuration and diagnostics |

| File System | Onboard file system for web pages and data (512 kByte) |

| BACnet Support | No |

SAIA PCD3.M6340

Product Introduction

The Saia PCD3.M6340 is a high-performance CPU base unit designed for industrial automation systems. It is part of the Saia PCD® COSinus operating system and offers a compact PLC solution with advanced communication capabilities. The module supports a wide range of communication interfaces, including USB, RS-232, RS-485, CAN, and Ethernet TCP/IP. It also features an integrated Web server and file system for easy configuration and diagnostics.

Core Advantages and Technical Highlights

Advanced Communication Capabilities:

Integrated high-speed CAN interface (up to 1 MBit/s) with galvanic isolation.

Ethernet TCP/IP interface supporting 10/100 Mbits, full-duplex, auto-sensing, and auto-crossing.

RS-232 and dual RS-485 interfaces for Profi-S-Net/MPI/S-Bus communication.

Robust and Reliable:

Designed to operate in harsh industrial environments with a wide temperature range (-25°C to +70°C).

Protection level IP 20 and flame resistance (UL 94 V0) for added safety.

User-Friendly Configuration and Diagnostics:

Integrated Web server and onboard file system for easy configuration and diagnostics.

USB port for PG5 configuration and diagnostics tool.

Flexible I/O Expansion:

Supports up to 1024 I/O points with expansion module holder.

Compatible with over 50 I/O modules in cassette form (PCD3.Axxx/ .Exxx/ .Wxxx/ .Bxxx/ .Hxxx).

SAIA PCD3.M6340

Typical Application Scenarios

The Saia PCD3.M6340 is widely used in various industrial sectors:

Manufacturing Plants: For real-time control and monitoring of production lines.

Power Generation Facilities: To monitor and control power plants and substations.

Water and Wastewater Treatment Plants: For controlling pumps and valves in water treatment processes.

Building Automation: For lighting, HVAC systems, and other automation equipment in large buildings.

Related Model Recommendations

Saia PCD3.A465: A digital output module with 16 transistor outputs, suitable for applications requiring precise control.

Saia PCD3.E165: A digital input module with 16 inputs, suitable for applications requiring precise monitoring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Ensure the environment meets the specified temperature and humidity requirements (0°C to +55°C, 10% to 95% RH non-condensing).

Use shielded cables and proper grounding to minimize electromagnetic interference.

Maintenance Suggestions:

Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation.

Perform annual full calibration and quarterly leak checks (He mass spec recommended).

Replace O-rings every 2 years and verify ground connections (impedance <1Ω).

Service and Guarantee Commitment

Saia-Burgess Controls AG stands behind the quality and reliability of the PCD3.M6340, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Their dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.