Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

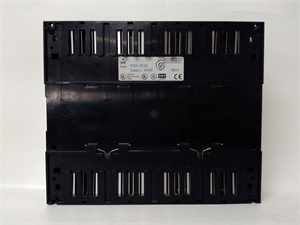

| Product model | SAIA PCD2.M110 |

| Manufacturer | Saia-Burgess |

| Product category | Programmable Controller |

| Operating Voltage | 24 VDC |

| Power Consumption | Max. 20 W |

| Input/Output Capacity | Up to 128 I/O points |

| Communication protocols | RS-232, RS-422/485, Profibus DP, Ethernet TCP/IP |

| Operating temperature | 0°C to +55°C (vertical installation), 0°C to +40°C (other installations) |

| Storage temperature | -25°C to +85°C |

| Humidity | 30% to 95%, non-condensing |

| Protection class | IP20 |

| Dimensions | 18.5 cm x 13.5 cm x 4.4 cm |

| Weight | 1.5 kg |

| Certifications | UL, CE compliant |

SAIA PCD2.M110

Product Introduction

The SAIA PCD2.M110 is a high-performance programmable controller designed for industrial automation and control systems. It is part of Saia-Burgess’s PCD® Classic series, known for its reliability and advanced technology in industrial control.

Core Advantages and Technical Highlights

High Precision Control: The PCD2.M110 provides precise control over industrial processes, optimizing efficiency and reducing operational costs.

Advanced Safety Features: The controller includes built-in safety features such as over-temperature and over-pressure monitoring, ensuring safe operation.

Versatile Fuel Support: The PCD2.M110 supports multiple communication protocols, making it suitable for a variety of industrial applications.

User-Friendly Interface: The controller features an intuitive interface for easy setup and monitoring of control parameters.

Remote Monitoring and Control: The PCD2.M110 supports remote monitoring and control via Ethernet, Modbus, CAN, and Profibus protocols, facilitating integration with SCADA systems.

SAIA PCD2.M110

Typical Application Scenarios

The SAIA PCD2.M110 is widely used in various industrial sectors, including:

Power Industry: Controlling and monitoring combustion processes in power plants.

Petrochemical Sector: Automating processes such as chemical mixing, refining, and storage.

General Automation: Controlling manufacturing processes, assembly lines, and robotic systems.

Related Model Recommendations

SAIA PCD2.M120: A related model with similar control capabilities but with extended I/O capacity.

SAIA PCD2.M150: Another model suitable for similar applications with additional features and higher processing power.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the SAIA PCD2.M110, ensure that the environment meets the specified requirements, including an operating temperature range of 0°C to +55°C for vertical installation and 0°C to +40°C for other installations. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail or panel mount for secure installation.

Maintenance Suggestions

To maintain the SAIA PCD2.M110, perform regular inspections of the unit and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.