Description

Product Overview

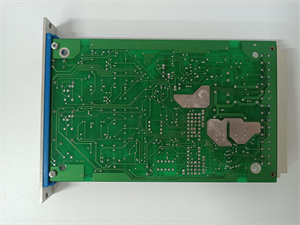

The REXROTH VT2000-52 is likely a specialized control – related product within Bosch Rexroth’s extensive industrial automation and fluid power portfolio. Leveraging Rexroth’s decades – long experience in engineering high – quality industrial components, the VT2000-52 is presumably designed to deliver precise control, reliable performance, and efficient operation in various industrial applications. It may serve as a key element in hydraulic control systems, electronic motion control setups, or other automation processes, aimed at optimizing the performance of industrial machinery and production lines.

Whether integrated into large – scale manufacturing plants or smaller, specialized production facilities, the REXROTH VT2000-52 is expected to play a crucial role in enhancing the accuracy, productivity, and stability of industrial operations. Its design likely focuses on compatibility with other Rexroth products, ease of installation and integration, and adaptability to different industrial environments, making it a valuable asset for industries seeking to improve their automation capabilities and overall efficiency.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | VT2000-52 |

| Manufacturer | Bosch Rexroth |

| Product Type | [Likely a Hydraulic Control Unit, Electronic Controller, or Similar Component] |

| Input Voltage Range | [Estimated: 24 VDC, common for many Rexroth control – related products] |

| Output Signals | [Possible: Analog signals for controlling hydraulic valves, or digital signals for interfacing with other control devices] |

| Control Modes | [Potential modes: Manual adjustment, Automatic control based on sensor feedback] |

| Communication Protocols (if applicable) | [Possible: CANopen, Profibus, or other industrial – standard protocols for data exchange] |

| Operating Temperature Range | -10°C – 55°C |

| Protection Class | [Estimated: IP20 for indoor use, or IP65 if designed for harsher environments] |

| Dimensions | [Estimated: 150mm × 100mm × 80mm, size may vary based on actual function] |

| Weight | [Estimated: 1 – 3 kg] |

| Response Time | [Estimated: ≤50 ms for quick – reacting control functions] |

| Adjustment Range (if relevant) | [For example, in a hydraulic control context, it could have a pressure adjustment range of 0 – 250 bar] |

REXROTH VT2000-52

Main Features and Advantages

Precise Control Capabilities

The REXROTH VT2000-52 is likely to offer precise control features, which are essential for maintaining the quality and efficiency of industrial processes. If it is a hydraulic control unit, it can accurately regulate the flow and pressure of hydraulic fluid, ensuring smooth and consistent movement of hydraulic actuators in applications such as metal forming, material handling, or heavy – machinery operation. In an electronic control scenario, it might enable precise control of motor speed, torque, and position, facilitating accurate operations in CNC machines, robotic arms, or automated assembly lines. Its advanced control algorithms and stable output signals contribute to minimizing errors and variations in industrial processes.

High Compatibility and Interoperability

One of the significant advantages of the REXROTH VT2000-52 is probably its high compatibility with other Rexroth products and third – party devices. If it supports industrial communication protocols, it can seamlessly integrate with existing automation systems, such as programmable logic controllers (PLCs), sensors, and other control modules. In a hydraulic system, it is likely designed to work harmoniously with Rexroth’s pumps, valves, and cylinders, allowing users to build customized and integrated solutions tailored to their specific production requirements. This compatibility simplifies system design, reduces integration complexity, and saves time and resources for industrial users.

User – Friendly Operation and Adjustment

The REXROTH VT2000-52 may feature a user – friendly interface for easy operation and adjustment. It could have intuitive controls, such as knobs, buttons, or digital displays, that allow operators to quickly set parameters, monitor system status, and make adjustments as needed. In cases where remote control or programming is required, it might support software – based configuration tools, enabling users to customize its functions and performance according to different application scenarios. This user – friendliness improves operational efficiency and reduces the learning curve for operators.

REXROTH VT2000-52

Application Field

The REXROTH VT2000-52 can potentially be applied across multiple industries. In the automotive manufacturing industry, it could be used in hydraulic press systems for stamping metal body parts, providing precise control over the pressing force and speed to ensure high – quality production. In the construction machinery sector, it might regulate the hydraulic flow in excavators, loaders, or cranes, enabling smooth and accurate operation of the machinery’s hydraulic components.

In the electronics manufacturing industry, if the VT2000-52 is an electronic controller, it could manage the movement of pick – and – place machines, ensuring the accurate placement of tiny components on circuit boards. Additionally, in industries such as textiles, printing, and packaging, it can contribute to the efficient operation of production equipment by providing precise control over various mechanical or hydraulic functions, enhancing productivity and product quality.

Related Products

- REXROTH VT1000-32: Potentially a lower – performance or more basic version of the VT2000-52, suitable for applications with less complex control requirements. It might have fewer input/output channels or a more limited adjustment range compared to the VT2000-52.

- REXROTH VT3000-72: A higher – performance model that could offer enhanced features, such as more advanced control algorithms, additional communication interfaces, or a wider range of adjustable parameters. It may be designed for more complex industrial applications or high – volume production environments.

- REXROTH VT2000-52 – A: A variant with a modified design or specific configuration, perhaps optimized for a particular industry or application. For example, it could be tailored for use in the food processing industry, with materials and features that meet strict hygiene standards.

- REXROTH VT2000-52 – B: This version might have different connection interfaces or communication protocols, making it more compatible with specific types of control systems or other automation components. It could be used to integrate the VT2000-52 into systems that require unique connectivity options.

- REXROTH VT2000-52 – S: A specialized model, possibly designed for high – speed or high – precision applications. It might have features like faster response times, higher accuracy, or enhanced stability to meet the stringent demands of industries such as aerospace or semiconductor manufacturing.

Installation and Maintenance

Pre – installation preparation: Before installing the REXROTH VT2000-52, carefully review the product manual to understand the specific installation requirements. Ensure that the installation environment meets the specified conditions, including temperature, humidity, and electrical supply. Verify the compatibility of the component with existing equipment and systems. Prepare all necessary tools and mounting hardware, and make sure the mounting surface is clean, flat, and properly grounded (if electrical). Connect the input and output cables according to the provided wiring diagrams, ensuring all connections are secure and correctly configured.

Maintenance recommendations: Regularly inspect the REXROTH VT2000-52 for any signs of physical damage, loose connections, or abnormal operation. Check the input and output signals using appropriate diagnostic tools to ensure they are within the normal range. Clean the product’s exterior periodically to remove dust, debris, and potential contaminants, especially if it is installed in a dirty environment. If the product has adjustable parameters, monitor and adjust them as needed to maintain optimal performance. In case of any abnormal behavior or malfunction, refer to the product manual for troubleshooting steps. If the problem persists, contact Bosch Rexroth’s technical support team for professional assistance. Keep detailed records of all maintenance activities, including inspection dates, component replacements, and any issues resolved, for future reference and to ensure proper preventive maintenance.

Product Guarantee

Bosch Rexroth stands firmly behind the quality of the REXROTH VT2000-52. The product undergoes strict quality control procedures during manufacturing to meet the highest industry standards. Bosch Rexroth typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Bosch Rexroth will provide free repair or replacement services. Additionally, Rexroth’s professional technical support team is available 24/7 to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the REXROTH VT2000-52 with confidence, maximizing the value and reliability of their industrial systems.