Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | REXROTH MKD071B-061-KG1-KN |

| Manufacturer | Bosch Rexroth |

| Product category | Synchronous AC Servo Motor |

| Operating Voltage | 115 V or 170 V |

| Rated Speed | 5000 min-1 |

| Continuous Torque at Standstill | 5.3 Nm |

| Peak Current Rating | 34 A |

| Rated Power | 4.8 kW |

| Thermal Time Constant | 45 minutes |

| Protection Rating | IP65 |

| Weight | 8.8 kg |

| Shaft Type | Plain Shaft (with Shaft Seal Ring) |

| Encoder Type | Resolver Feedback with Integrated Multiturn Absolute Encoder |

| Holding Brake | 22 Nm Holding Torque, Clamping Delay: 14 ms, Release Delay: 28 ms |

| Insulation Class | Class F |

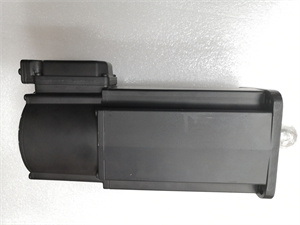

| Housing Color | Black (RAL 9005) |

| Maximum Setup Height | Up to 1000 meters above sea level |

REXROTH MKD071B-061-KG1-KN

Product Introduction

The REXROTH MKD071B-061-KG1-KN is a high-performance digital AC synchronous servo motor designed for precise motion control in industrial automation systems. It is part of the MKD series and is known for its high torque performance, IP65 protection, and durable RAL 9005 housing. This motor is suitable for applications requiring consistent torque and position accuracy.

Core Advantages and Technical Highlights

High Precision and Reliability:

The REXROTH MKD071B-061-KG1-KN offers high-precision motion control with an integrated multiturn absolute encoder, ensuring reliable performance in demanding industrial environments.

Robust Industrial Design:

The motor features an IP65 protection rating, safeguarding it from dust and low-pressure water jets. This ensures durability in harsh industrial conditions.

Versatile Applications:

The REXROTH MKD071B-061-KG1-KN is suitable for a wide range of applications, including manufacturing, energy, material handling, and robotics.

Easy Integration:

The motor features industry-standard communication protocols and interfaces, ensuring seamless integration with existing systems.

Advanced Safety Features:

The motor includes a holding brake with a holding torque of 22 Nm, ensuring enhanced safety and ease of troubleshooting.

REXROTH MKD071B-061-KG1-KN

Typical Application Scenarios

The REXROTH MKD071B-061-KG1-KN is widely used in various industrial sectors:

Manufacturing: For precise control in assembly lines and machine tools.

Energy: For pump control in water treatment plants.

Material Handling: For conveyor speed control in automotive assembly lines.

Food and Beverage Production: For controlling motion equipment on production lines.

Related Model Recommendations

REXROTH MKD071B-024: A similar model with lower power output, suitable for applications requiring lower torque.

REXROTH MKD090B-035: A model with higher power capacity, suitable for applications requiring higher torque.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation:

Ensure the installation environment meets the specified temperature and humidity requirements. The motor should be installed in a location with adequate ventilation to dissipate heat. Verify that the power supply voltage is within the specified range (115 V or 170 V) to avoid damage to the motor.

Maintenance Suggestions:

Regularly inspect the installation to ensure the motor is securely mounted and all connections are tight. Monitor the operational status of the motor to detect any signs of malfunction early. Conduct functional testing on the motor at least once a year to ensure optimal performance.

Service and Guarantee Commitment

Bosch Rexroth provides comprehensive support for the REXROTH MKD071B-061-KG1-KN, including a robust warranty that ensures product quality and reliability. The company offers extensive after-sales services such as technical support, repair services, and spare part supply. Bosch Rexroth’s global network of service centers ensures prompt assistance and expert guidance, demonstrating the company’s commitment to customer satisfaction and product excellence.