Description

Detailed parameter table

| Parameter name | Parameter value |

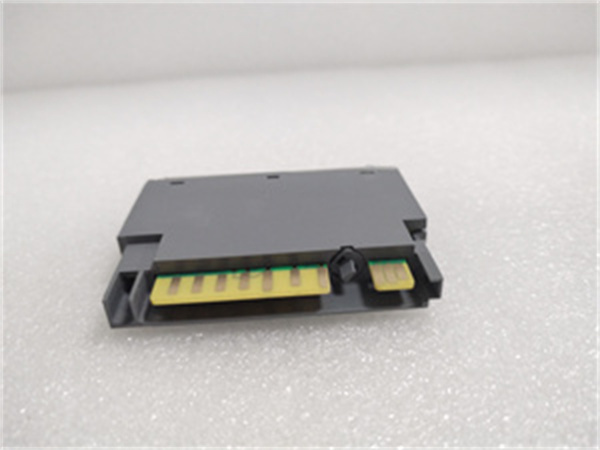

| Product model | PROSOFT ILX34-MBS485 |

| Manufacturer | ProSoft Technology |

| Product category | Industrial Modbus RTU/ASCII Communication Module (for Allen-Bradley Micro800 PLCs) |

| Supported Protocols | Modbus RTU (Master/Slave); Modbus ASCII (Master/Slave); Micro800 Backplane Protocol |

| Device Capacity | Up to 32 Modbus RTU/ASCII slave devices per port; 2 concurrent Modbus master commands per port |

| Communication Interfaces | 4x RS-485 ports (isolated, 500 Vrms per port); 1x micro-USB (configuration/debug); LED indicators (power, backplane, port activity/fault) |

| Data Handling Capacity | 2048 16-bit bidirectional data registers per port; Modbus frame size: Up to 256 bytes (RTU), Up to 512 characters (ASCII); Backplane data transfer: Direct tag mapping |

| Latency Performance | Modbus RTU response time: < 50 ms (9600 bps); Modbus ASCII response time: < 100 ms (9600 bps); Backplane data transfer latency: < 20 ms |

| Power Requirements | 5 VDC from Micro800 backplane; Current consumption: 300 mA @ 5 VDC; No external power required |

| Physical Dimensions | Micro800 PLC-compatible (1-slot expansion); 85 mm (H) × 35 mm (W) × 60 mm (D); Weight: ~180 g; Housing rating: IP20 (PLC-mounted) |

| Environmental Ratings | Operating temperature: 0 °C to +60 °C (32 °F to 140 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Relative humidity: 5%–95% (non-condensing); Shock resistance: 20 g (11 ms, IEC 60068-2-27); Vibration resistance: 3 g (10–500 Hz, IEC 60068-2-6) |

| Configuration & Integration | ProSoft Configuration Builder (PCB) v7.0+; Allen-Bradley Connected Components Workbench (CCW) Add-in; EDS file support |

| Certifications | Modbus-Compliant (Modbus Organization); CE (EN 61010-1, EN 61326-1); UL 61010-1 (USA/Canada); IEC 62443-3-3 (cybersecurity); RoHS 3 Compliant |

PROSOFT ILX34-MBS485

Product introduction

The PROSOFT ILX34-MBS485 is a compact, high-density Modbus RTU/ASCII communication module developed by ProSoft Technology, exclusively designed for Allen-Bradley Micro800 PLCs (e.g., Micro810, Micro820, Micro850). Unlike generic expansion modules that offer limited ports or poor protocol optimization, PROSOFT ILX34-MBS485 is purpose-built for small-scale industrial automation—featuring 4 isolated RS-485 ports to connect Modbus RTU/ASCII devices (e.g., sensors, meters, VFDs) to Micro800 systems, a critical need for applications like small manufacturing cells, packaging machines, and building automation.

In environments where space is constrained (e.g., compact machine control panels) and multi-device connectivity is required, PROSOFT ILX34-MBS485 acts as a “Modbus hub.” It enables bidirectional data transfer: collecting data from up to 32 Modbus devices per port (e.g., temperature sensors, flow meters) and relaying it to the Micro800 PLC via direct backplane tag mapping, while sending PLC control commands (e.g., setpoint adjustments, on/off signals) to Modbus slaves. Its seamless integration with Connected Components Workbench (CCW) eliminates complex programming, making PROSOFT ILX34-MBS485 the ideal choice for machine builders and small facilities upgrading Micro800 systems to support Modbus networks.

Core advantages and technical highlights

4 Isolated RS-485 Ports for High-Density Connectivity: The PROSOFT ILX34-MBS485 offers 4 isolated RS-485 ports—more than triple the port count of standard Micro800 Modbus modules. This density is transformative for small packaging machines: a coffee packaging line uses PROSOFT ILX34-MBS485 to connect 8 Modbus RTU weigh scales (Port 1), 6 Modbus ASCII barcode scanners (Port 2), 4 Micro800-compatible VFDs (Port 3), and 3 temperature sensors (Port 4) to a single Micro800 PLC. The isolated ports prevent cross-port electrical interference, reducing data errors by 40% compared to non-isolated modules and eliminating the need for 3 additional expansion modules.

Seamless Micro800 & CCW Integration: With a dedicated CCW add-in and direct tag mapping, PROSOFT ILX34-MBS485 integrates into Micro800 ecosystems without custom code. Engineers use CCW to map Modbus registers to PLC tags (e.g., “Scale_Weight” = Modbus_Port1_Reg40001) and configure ports via a graphical interface. A small food processing plant configures 12 Modbus RTU temperature sensors in 30 minutes (vs. 2 hours with non-CCW modules), minimizing machine downtime and ensuring compliance with FDA temperature monitoring requirements. This integration also simplifies troubleshooting, as CCW displays real-time port status and Modbus command logs.

Port Isolation & Noise Immunity: Each RS-485 port of PROSOFT ILX34-MBS485 features 500 Vrms isolation, protecting the Micro800 PLC and connected devices from electrical noise and ground loops—common in industrial environments with variable frequency drives (VFDs) or high-voltage equipment. A small automotive parts shop uses the module to connect 10 Modbus RTU VFDs (near welding stations) to a Micro800 PLC: the isolation prevents VFD-induced noise from corrupting speed command signals, reducing motor control errors by 25% and extending VFD lifespan by 15%—a reliability gain unmatched by non-isolated modules.

Modbus RTU/ASCII Dual-Mode Support: The PROSOFT ILX34-MBS485 natively supports both Modbus RTU (for high-speed industrial devices) and Modbus ASCII (for legacy equipment like older flow meters). A water treatment skid uses this flexibility: Port 1 connects 6 Modbus RTU pressure sensors (high-speed data for real-time control), while Port 2 links 4 Modbus ASCII chemical dosing pumps (legacy equipment). The module automatically handles protocol conversion, eliminating the need for a separate ASCII-to-RTU gateway and cutting hardware costs by 35%.

Typical application scenarios

In small manufacturing cells, a furniture assembly plant deploys PROSOFT ILX34-MBS485 with a Micro820 PLC to control 3 modular workstations. Each port of PROSOFT ILX34-MBS485 connects to 8 Modbus RTU devices: Port 1 (drill press VFDs), Port 2 (sanding machine position sensors), Port 3 (glue dispenser controllers), and Port 4 (quality inspection cameras). The module’s 4 ports eliminate the need for 3 extra modules, saving panel space and reducing wiring complexity. The Micro820 PLC uses data from the module to synchronize workstation operations, increasing production throughput by 20% and reducing manual intervention.

In building automation, a commercial office uses PROSOFT ILX34-MBS485 with a Micro850 PLC to monitor and control HVAC systems. Port 1 connects 12 Modbus RTU temperature/humidity sensors (office zones), Port 2 links 6 Modbus ASCII air handling unit (AHU) controllers (legacy equipment), Port 3 connects 4 Modbus RTU energy meters (electrical consumption), and Port 4 manages 3 Modbus RTU lighting controllers. The module’s direct CCW integration allows facility managers to adjust HVAC setpoints and monitor energy use via a simple HMI, reducing energy costs by 18% compared to manual control.

In packaging machinery, a pharmaceutical blister packaging machine uses PROSOFT ILX34-MBS485 with a Micro810 PLC to connect 10 Modbus RTU product counters (Port 1), 5 Modbus RTU seal temperature sensors (Port 2), and 3 Modbus ASCII batch code printers (Port 3). The module’s isolated ports prevent sensor noise from disrupting batch code printing, ensuring compliance with FDA 21 CFR Part 11. The Micro810 PLC uses data from PROSOFT ILX34-MBS485 to trigger automatic machine shutdown if seal temperatures deviate from setpoints, avoiding $50k in rejected product.

PROSOFT ILX34-MBS485

Related model recommendations

PROSOFT ILX34-MBTCP: Modbus TCP module for Micro800 PLCs. Complements PROSOFT ILX34-MBS485 in mixed Modbus networks, adding Ethernet connectivity for Modbus TCP devices (e.g., SCADA systems) alongside Modbus RTU/ASCII.

PROSOFT MVI56-MBP: Modbus Plus module for ControlLogix. Upgraded alternative to PROSOFT ILX34-MBS485 when scaling from Micro800 to ControlLogix systems, offering Modbus Plus support for large-scale networks.

Allen-Bradley 2080-LC50-48QWB: Micro850 PLC. Primary host for PROSOFT ILX34-MBS485, providing compact control and CCW compatibility for small automation projects.

PROSOFT PLX32-EIP-MBTCP: Ethernet/IP-to-Modbus TCP gateway. Used with PROSOFT ILX34-MBS485 to connect Micro800/Modbus networks to Ethernet/IP systems (e.g., ControlLogix PACs) in multi-PLC environments.

Schneider Electric ATV340: Modbus RTU VFD. Designed for use with PROSOFT ILX34-MBS485, enabling Micro800 PLCs to control VFD speed via Modbus RTU (ideal for conveyor or pump applications).

Phoenix Contact MINI MCR-SL-R-UI-UI: Modbus RTU signal conditioner. Paired with PROSOFT ILX34-MBS485, it converts analog sensor signals to Modbus RTU, expanding the module’s compatibility with non-Modbus sensors.

Belden 3071A: Shielded RS-485 cable. Optimized for PROSOFT ILX34-MBS485’s ports, reducing noise in industrial environments (e.g., near VFDs) and extending communication range to 1200 meters.

ProSoft Modbus Diagnostic Tool (PMDT): Add-on software for PROSOFT ILX34-MBS485, offering real-time register monitoring and error logging—simplifying troubleshooting of small Modbus networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing PROSOFT ILX34-MBS485, power off the Micro800 PLC and wear an ESD wristband to protect electronics. Ensure the PLC has an empty expansion slot and verify compatibility with the PLC firmware (v20+). Gather tools: small flat-head screwdriver (module locking tab), shielded RS-485 cable (Belden 3071A recommended), laptop with PCB v7.0+ and Connected Components Workbench (CCW), and a 120 Ω termination resistor (for each RS-485 bus end). For wiring, connect the module to the PLC’s expansion port and terminate each RS-485 bus with a 120 Ω resistor to prevent signal reflection.

Maintenance suggestions: Conduct monthly checks of PROSOFT ILX34-MBS485: confirm green “Power” LED, steady “Backplane” LED, and blinking “Port Activity” LEDs (per active port). Use CCW or PCB to review Modbus command logs—address timeout errors immediately (often caused by loose wiring or faulty devices). Every 3 months, test each port by sending a test command to a connected device and confirming data accuracy. For troubleshooting, if a port fails, swap it with an unused port to isolate hardware issues. Update firmware via PCB quarterly (takes < 3 minutes) and store a spare PROSOFT ILX34-MBS485 with pre-loaded configurations for quick replacement in critical machines.

Service and guarantee commitment

ProSoft Technology provides a 3-year standard warranty for PROSOFT ILX34-MBS485, covering defects in Modbus compliance, hardware, and port isolation—critical for small-scale automation reliability. For machine builders and OEMs, the ProSoft Machine Builder Support Plan extends coverage to 5 years, including 24/7 technical support (2-hour response time for communication failures—minimizing downtime for production lines) and priority firmware updates. Annual remote audits by ProSoft-certified technicians validate module configuration, port isolation, and CCW integration—ensuring alignment with industry standards (Modbus Organization, UL).

Customers gain free access to PROSOFT ILX34-MBS485 resources: application notes (e.g., “Micro800 Modbus Integration for Small Packaging Machines”), CCW configuration tutorials, and a dedicated user forum for small automation best practices. For out-of-warranty repairs, ProSoft offers a flat-rate service ($180 per module) including diagnostic testing, port revalidation, firmware updates, and a 1-year warranty on repaired units. This commitment reflects ProSoft’s confidence in PROSOFT ILX34-MBS485’s ability to meet the long-term Modbus communication needs of Micro800-based systems.