Description

Key Technical Specifications

| Technical Item | Details |

|---|---|

| Manufacturer | National Instruments (NI) |

| Channel Count | 8 independent isolated analog input channels |

| Isolation Performance | 250Vrms working isolation per channel, realizing isolation between channels and between channels and the earth |

| Input Signal Support | Thermocouple, millivolt, volt, 0 – 20mA and 4 – 20mA current signals; strain gauges, RTDs and thermistors can be measured with external excitation |

| Input Range | Configurable via jumpers, with an output range of ±5V; can be extended to ±1000VDC with TBX – 1316 terminal block |

| Gain Adjustment | Multiple gain options including 1, 2, 5, 10, 20, 50, 100, 200, 250, 500, 1000, 2000 |

| Filter Configuration | Jumper – configurable low-pass filter per channel, optional 4Hz or 10kHz |

| Output Modes | Parallel – output mode (8 input channels connected in parallel to 8 DAQ channels) and multiplexed – output mode (8 channels multiplexed into 1 DAQ channel) |

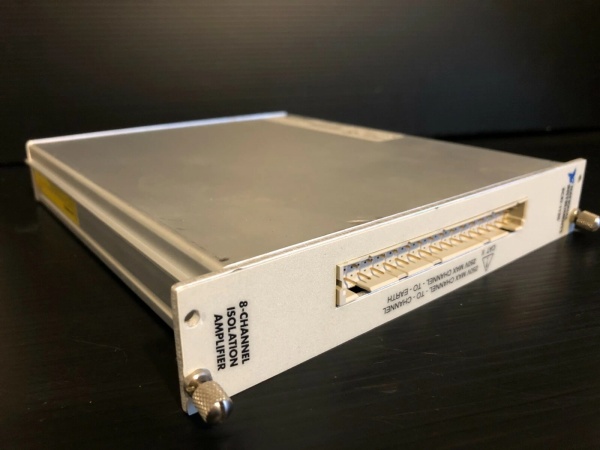

| Connectors | 50 – pin male ribbon – cable rear connector, 32 – pin DIN C male front connector; 18 – screw terminal adapter is optional |

| Operating Temperature | 0°C – 50°C |

| Physical Dimensions | 1.2×6.8×8.0 inches |

| Chassis Compatibility | Compatible with SCXI – 1000, SCXI – 1000 DC, SCXI – 1001, SCXI – 2000 chassis |

NI SCXI-1120

Field Application & Problem Solved

In industrial production lines and laboratory test scenarios, weak signals like millivolt – level sensor outputs and thermocouple temperature signals are prone to two major problems. One is interference from high common – mode voltages and electromagnetic noise in the field, which leads to distorted measurement data. The other is that the signal amplitude is too small to be directly collected by general DAQ devices. Besides, different types of sensors have different signal ranges, which makes it difficult for a single acquisition module to adapt to various testing requirements.

The NI SCXI – 1120 solves these pain points effectively. Its 250Vrms independent channel isolation can avoid interference caused by common – mode voltages between channels and between channels and the earth, ensuring the accuracy of weak signal transmission. The multi – level gain adjustment (up to 2000 times) can amplify weak signals such as millivolt – level signals to the ±5V output range suitable for DAQ devices. Meanwhile, the configurable low-pass filter can filter out high – frequency noise and retain effective signal components.

It is often used in scenarios such as factory production line temperature and pressure monitoring (connecting thermocouples and pressure sensors), laboratory electronic component performance testing (processing small current and voltage signals), and industrial process control (collecting 4 – 20mA standard industrial current signals). For example, in an automobile parts durability test bench, the module can isolate and condition the weak temperature signals from multiple thermocouples on the engine, ensuring that the DAQ system collects stable and accurate data even in the high – interference environment of the test bench.

Installation & Maintenance Pitfalls (Expert Tips)

- Chassis and Hardware Matching: The module must rely on specific SCXI chassis such as SCXI – 1000 and SCXI – 1001 to work. Using incompatible chassis will result in failure to power on or communicate. When connecting to a DAQ device, pay attention to the module version. For revisions A and B, the MISO line can only be used in a single chassis; for revisions C and later, jumpers W42 and W43 can be kept in position 1, which is more flexible in multi – chassis applications.

- Gain and Filter Jumper Configuration: Wrong jumper settings will lead to signal distortion or failure to collect signals. For example, if a 4Hz low-pass filter is mistakenly configured for a high-frequency dynamic signal, the signal will be excessively smoothed. When configuring the gain, it is necessary to match the input signal amplitude. For example, a 2.5mV weak signal needs to be amplified with a high gain such as 2000 times, while a 5V signal only needs a gain of 1 to avoid signal clipping.

- Terminal Block Selection for High – Voltage Signals: The module’s inherent input range is limited to ±5V. When it is necessary to measure high – voltage signals up to ±1000VDC, the TBX – 1316 terminal block must be used. Using ordinary terminal blocks will not only fail to measure normally but also may damage the module due to overvoltage. If measuring ±250V signals, the SCXI – 1327 high – voltage attenuator terminal block should be selected.

- Output Mode Selection Based on Test Requirements: In the case of limited DAQ channels, the multiplexed – output mode can multiplex 8 channels into one DAQ channel to save resources, but it will reduce the scanning rate. When high – speed simultaneous acquisition of 8 channels is required, the parallel – output mode should be adopted, and it should be ensured that the DAQ device has enough matching channels. Choosing the wrong mode will affect the test efficiency or data integrity.

NI SCXI-1120

Technical Deep Dive & Overview

The core advantage of the NI SCXI – 1120 lies in its balanced design of isolation performance and signal conditioning flexibility, which is tailored to the pain points of weak signal acquisition in industrial and laboratory environments. Its independent isolation design for each channel is the key to resisting common – mode interference. In industrial sites, different devices often have ground potential differences, and this isolation design can cut off the interference path, which is irreplaceable for ensuring the reliability of thermocouples and other weak signal acquisition.

In terms of signal processing, the module’s dual working modes meet different test needs. The multiplexed – output mode is suitable for scenarios with few DAQ channels and low real – time requirements, such as long – term environmental monitoring. The parallel – output mode can realize high – speed simultaneous scanning of 8 channels, which is applicable to dynamic test scenarios such as mechanical vibration signal collection. The 12 – level gain adjustment covers the amplification needs of most weak signals, and the two – gear low-pass filter can be targeted to deal with different frequency signal noise.

In terms of hardware design, the dual – connector design of the module (50 – pin rear ribbon connector and 32 – pin front DIN connector) facilitates different wiring modes. The optional screw terminal adapter makes on – site wiring and disassembly more convenient. However, it should be noted that the module has no volatile or non – volatile memory, and the configuration parameters need to be reset through software or jumpers after power – off.

In terms of software compatibility, it supports LabVIEW, LabWindows/CVI and other NI common programming software, and can be seamlessly integrated with the NI – DAQ driver. Users do not need to develop complex drivers, which reduces the difficulty of system construction. Although it has been obsolete, its stable performance and mature application ecosystem make it still an important part of many legacy test systems.