Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXIE-7975 |

| Manufacturer | National Instruments (NI) |

| Product Category | PXIe Embedded Controller |

| Processor | Intel Core i7-4700EQ quad-core processor, 2.4 GHz (up to 3.4 GHz with Turbo Boost) |

| Memory | 8 GB DDR3L SDRAM (up to 16 GB) |

| Storage | 500 GB 2.5-inch SATA hard drive; optional 128 GB/256 GB SSD |

| PXIe Interface | x4 PCIe Gen 3 link to backplane |

| Operating System | Windows 7 Professional (32-bit/64-bit), Windows 10 Enterprise LTSB |

| I/O Ports | 2 USB 3.0 ports, 4 USB 2.0 ports, 1 Gigabit Ethernet port, 1 serial port (RS-232), 1 VGA port, 1 DisplayPort |

| Expansion Slots | 1 PCIe Mini Card slot (for wireless modules), 1 mSATA slot |

| Power Consumption | 65 W typical |

| Operating Temperature Range | 0 to 55 °C |

| Storage Temperature Range | -40 to 70 °C |

| Humidity Range | 5 to 95% non-condensing (operating), 5 to 95% non-condensing (storage) |

| Physical Dimensions | 16.5 cm (height) x 10.7 cm (width) x 20.3 cm (depth) |

| Weight | 1.8 kg |

| Compliance | CE, UL, CSA, FCC Part 15 Class B |

| Software Compatibility | LabVIEW, LabWindows/CVI, Measurement Studio, NI TestStand, Visual Studio |

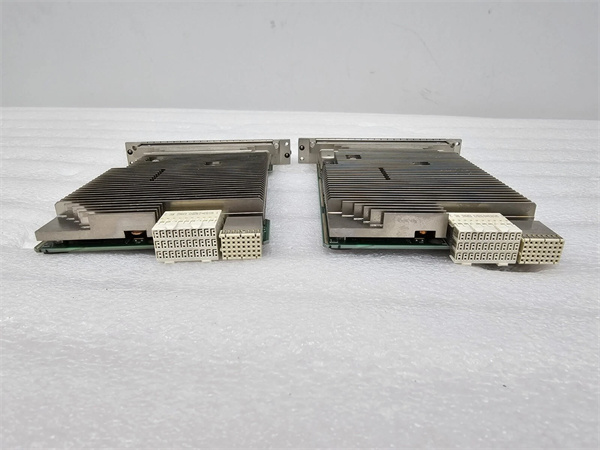

NI PXIE-7975

2. Product Introduction

The NI PXIE-7975 is a high-performance embedded controller designed for PXIe chassis, serving as the computational core of modular test and measurement systems. It combines powerful processing capabilities with seamless integration into PXIe architectures, making it an ideal choice for applications requiring real-time data processing, test automation, and high-speed communication with PXIe modules.

Powered by an Intel Core i7-4700EQ quad-core processor, the PXIE-7975 delivers robust computing performance, capable of handling complex algorithms and large datasets. Its 8 GB DDR3L memory (expandable to 16 GB) ensures smooth multitasking, while the 500 GB SATA hard drive (or optional SSD) provides ample storage for test programs, data logs, and operating system files.

With a x4 PCIe Gen 3 link to the PXIe backplane, the controller enables high-speed data transfer between itself and connected modules—critical for applications like high-speed signal acquisition and real-time control. Its 丰富的 I/O ports facilitate connectivity with external devices, such as monitors, printers, and network equipment, enhancing system versatility.

3. Core Advantages and Technical Highlights

Powerful Processing Performance

The Intel Core i7-4700EQ processor in the PXIE-7975 offers quad-core processing with Turbo Boost technology, delivering up to 3.4 GHz for demanding tasks. This power is essential for applications like real-time signal processing in radar testing, where large amounts of data must be analyzed instantaneously to extract meaningful insights. For example, in a wireless communication test system, the controller can process modulation analysis data from a vector signal analyzer module (such as PXIe-5663) in real time, enabling rapid validation of device performance.

High-Speed Backplane Connectivity

The x4 PCIe Gen 3 link provides a dedicated bandwidth of up to 8 GB/s to the PXIe backplane, ensuring fast data exchange between the controller and modules. This high-speed connection minimizes latency in data transfer, which is crucial for time-critical applications like closed-loop control systems. In an industrial automation setup, the PXIE-7975 can quickly receive sensor data from a DAQ module (e.g., PXIe-6368) and send control signals to an actuator module, maintaining precise control over manufacturing processes.

Flexible Expansion Options

The PXIE-7975 features a PCIe Mini Card slot and an mSATA slot, allowing users to add wireless connectivity (e.g., Wi-Fi/Bluetooth) or additional storage. This flexibility is valuable in remote test setups, where wireless communication enables remote monitoring and control of the system. For instance, in a field-testing scenario for aerospace components, a Wi-Fi module installed in the controller allows engineers to access test data and adjust parameters from a mobile device, eliminating the need for physical connection to the system.

Rugged Design for Industrial Environments

With an operating temperature range of 0 to 55 °C and compliance with industrial standards, the PXIE-7975 is built to withstand harsh environments. Its rugged construction ensures reliable operation in factory floors, aerospace test cells, and other demanding settings. The controller’s resistance to vibration and shock further enhances its suitability for mobile test systems, such as those mounted on vehicles for on-site equipment diagnostics.

4. Typical Application Scenarios

Automated Test Systems

In electronics manufacturing, the PXIE-7975 serves as the controller for automated test systems (ATS). It coordinates the operation of PXIe modules such as signal generators (PXIe-5450), digitizers (PXIe-5186), and switching modules (PXIe-2597) to perform functional testing of printed circuit boards (PCBs) or integrated circuits (ICs). The controller’s processing power enables rapid execution of test sequences, reducing test time per unit and increasing production throughput.

Aerospace and Defense Test Rigs

Aerospace engineers use the PXIE-7975 in test rigs for avionics, propulsion systems, and radar components. The controller processes data from sensors measuring temperature, pressure, and vibration, while synchronizing with RF modules to test communication systems. Its high-speed backplane connection ensures that data from multiple modules is time-aligned, enabling accurate analysis of system behavior under simulated flight conditions.

Industrial Control and Monitoring

In industrial plants, the PXIE-7975 integrates with PXIe modules to form a control and monitoring system. It collects data from process sensors via DAQ modules, processes the information to detect anomalies, and sends control signals to actuators to adjust process parameters. For example, in a chemical processing plant, the controller can monitor pH levels and flow rates, automatically adjusting valves to maintain optimal reaction conditions and ensure product quality.

Research and Academic Labs

Research facilities utilize the PXIE-7975 to power custom measurement systems for scientific experiments. It controls specialized PXIe modules such as lock-in amplifiers (PXIe-5610) and waveform generators to conduct experiments in physics, materials science, and biomedical engineering. The controller’s compatibility with programming environments like LabVIEW allows researchers to develop custom data acquisition and analysis tools tailored to their specific experimental needs.

NI PXIE-7975

5. Related Model Recommendations

PXIe Chassis

The PXIE-7975 is designed to work with PXIe chassis such as the PXIE-1085 (18-slot) or PXIE-1071 (7-slot). These chassis provide the backplane infrastructure for connecting the controller to other PXIe modules, enabling the creation of scalable test systems. The PXIE-1085’s high bandwidth and multiple slots make it ideal for large-scale systems requiring numerous modules.

Data Acquisition Modules

Pair the PXIE-7975 with the PXIe-6368 DAQ module for analog and digital signal acquisition. This combination is suitable for applications like environmental monitoring, where the controller processes data from temperature, humidity, and pressure sensors in real time.

RF and Signal Generation Modules

For RF testing applications, combine the controller with the PXIe-5673 RF signal generator and PXIe-5663 vector signal analyzer. The PXIE-7975 can generate complex test waveforms, control the signal generator, and analyze the received signals to validate the performance of wireless devices.

Software Tools

Enhance system functionality with NI software such as LabVIEW for graphical programming, TestStand for test sequence management, and DIAdem for data analysis and reporting. These tools integrate seamlessly with the PXIE-7975, simplifying system development and operation.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Ensure the PXIe chassis (e.g., PXIE-1085) is powered off before installing the PXIE-7975. Insert the controller into the chassis’s system slot, aligning it with the guide rails, and secure it with the front panel screws. Connect external devices (monitor, keyboard, mouse) via the I/O ports. Power on the chassis and follow the on-screen prompts to install the operating system if not pre-installed.

Commissioning Steps

Launch NI MAX to verify recognition of the controller and connected modules. Install necessary drivers for PXIe modules using NI Driver Suite. Configure network settings to enable communication with other devices or a central server. Run a test application (e.g., a LabVIEW VI) to validate data transfer between the controller and modules, ensuring proper synchronization and functionality.

Maintenance Suggestions

Regularly update the controller’s firmware and drivers via NI Update Service to ensure compatibility with new modules and software. Monitor storage health using disk utility tools; consider using an SSD for improved reliability and performance. Clean the controller’s vents periodically to prevent dust buildup, which can cause overheating. Back up critical data and test programs to an external storage device or network drive to prevent data loss.

7. Service and Guarantee Commitment

NI provides a 3-year standard warranty for the PXIE-7975, covering defects in materials and workmanship. During the warranty period, NI offers technical support via online resources, email, and phone, assisting with installation, configuration, and troubleshooting. For out-of-warranty units, NI provides repair and upgrade services, including memory expansion and storage replacement. With a focus on reliability and customer satisfaction, NI ensures that the PXIE-7975 delivers consistent performance in critical test and measurement applications.