Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-8105 |

| Manufacturer | National Instruments (NI) |

| Product Category | PXI Embedded Controller |

| Processor | Intel Core 2 Duo T7400, 2.16 GHz |

| Memory | 2 GB DDR2 SDRAM (up to 4 GB) |

| Storage | 80 GB 2.5-inch SATA hard drive; optional 64 GB SSD |

| PXI Interface | 32-bit/33 MHz PCI interface to PXI backplane |

| Operating System | Windows XP Professional, Windows 7 Professional (32-bit) |

| I/O Ports | 2 USB 2.0 ports, 1 Gigabit Ethernet port, 1 serial port (RS-232), 1 VGA port, 1 parallel port |

| Expansion Slots | 1 PCIe Mini Card slot (for wireless modules) |

| Power Consumption | 30 W typical |

| Operating Temperature Range | 0 to 55 °C |

| Storage Temperature Range | -20 to 70 °C |

| Humidity Range | 5 to 95% non-condensing (operating), 5 to 95% non-condensing (storage) |

| Physical Dimensions | 16.5 cm (height) x 10.7 cm (width) x 20.3 cm (depth) |

| Weight | 1.6 kg |

| Compliance | CE, UL, CSA, FCC Part 15 Class B |

| Software Compatibility | LabVIEW, LabWindows/CVI, Measurement Studio, NI TestStand, Visual Studio |

NI PXI-8105

2. Product Introduction

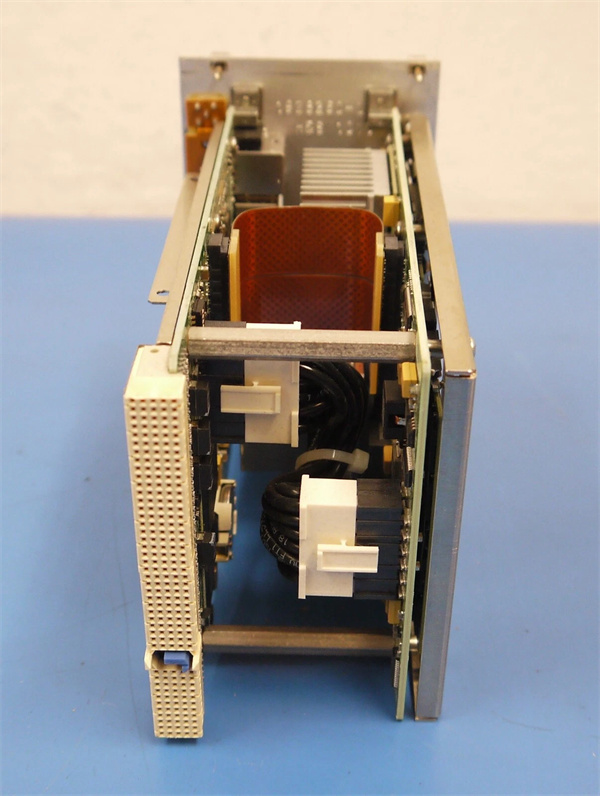

The NI PXI-8105 is a reliable embedded controller designed for PXI chassis, serving as the central processing unit for modular test and measurement systems. It combines solid computing performance with seamless integration into PXI architectures, making it suitable for applications ranging from automated testing to industrial control.

Powered by an Intel Core 2 Duo T7400 processor running at 2.16 GHz, the PXI-8105 offers sufficient processing power to handle data acquisition, analysis, and system control tasks. Its 2 GB DDR2 memory (expandable to 4 GB) supports multitasking, allowing simultaneous operation of test software, data logging, and communication with external devices. The 80 GB SATA hard drive provides ample storage for operating systems, test programs, and measurement data, with an optional SSD available for enhanced durability and faster data access.

With a 32-bit/33 MHz PCI interface to the PXI backplane, the controller enables communication with PXI modules, facilitating data transfer and synchronization in multi-module systems. Its diverse I/O ports, including USB, Ethernet, and serial ports, ensure connectivity with peripherals such as monitors, keyboards, and network devices, enhancing system versatility.

3. Core Advantages and Technical Highlights

Balanced Processing Performance

The Intel Core 2 Duo T7400 processor in the PXI-8105 delivers dual-core performance, making it capable of handling moderate to complex test and measurement tasks. In automated test systems, it can efficiently run test sequences, process data from DAQ modules (such as the PXI-6251), and generate real-time reports. For example, in a component testing setup, the controller can analyze analog measurements from the PXI-6251, compare results against specifications, and log pass/fail data—all without performance bottlenecks.

Seamless PXI Integration

The 32-bit/33 MHz PCI interface ensures reliable communication with PXI modules, supporting data transfer rates suitable for many mid-range applications. This integration is crucial for maintaining synchronization between the controller and modules in time-sensitive setups. In a vibration testing system, for instance, the PXI-8105 can coordinate with a signal generator module to produce excitation signals while receiving and processing vibration data from an accelerometer connected to the PXI-6251, ensuring precise timing between stimulus and measurement.

Compact and Rugged Design

The PXI-8105’s compact form factor fits seamlessly into PXI chassis, saving space in rack-mounted or portable systems. Its rugged construction, with an operating temperature range of 0 to 55 °C, allows it to operate reliably in industrial environments, such as factory floors or field-testing locations. This durability makes it suitable for applications where equipment must withstand temperature fluctuations and minor vibrations.

Flexible Connectivity

Equipped with multiple I/O ports, the PXI-8105 offers flexible connectivity options. The Gigabit Ethernet port enables high-speed communication with networked devices, such as centralized data servers or remote monitoring stations. USB ports support peripherals like external hard drives for data backup or barcode scanners for test item tracking. In a production line test station, this connectivity allows the controller to share test results with a factory-wide MES (Manufacturing Execution System) and receive test recipes from a central server.

4. Typical Application Scenarios

Automated Test Systems (ATS)

In electronics manufacturing, the PXI-8105 serves as the controller for ATS, managing PXI modules such as the PXI-6251 (DAQ), signal generators, and switching modules. It executes test sequences via NI TestStand, controls module operations, and processes measurement data to determine device pass/fail status. For example, in testing printed circuit boards (PCBs), the controller commands the PXI-6251 to measure voltage levels at various test points, compares the results to expected values, and logs the data for quality control analysis.

Industrial Control Systems

The PXI-8105 is used in industrial control systems to monitor and regulate manufacturing processes. It interfaces with DAQ modules (e.g., PXI-6251) to collect data from sensors measuring temperature, pressure, and flow rate, then uses this data to adjust actuators or send alerts via digital I/O. In a food processing plant, the controller can maintain precise oven temperatures by analyzing thermocouple data from the PXI-6251 and adjusting heating elements, ensuring product consistency.

Research and Laboratory Automation

Research labs utilize the PXI-8105 to automate experimental setups. It controls PXI modules to generate stimuli, acquire data, and log results. In a material science lab, for instance, the controller can coordinate with the PXI-6251 to measure strain in a sample under varying loads, control a motorized test frame via digital I/O, and record data for later analysis in LabVIEW. This automation reduces manual intervention, improving experiment repeatability.

Aerospace Component Testing

In aerospace testing facilities, the PXI-8105 controls systems for testing components like sensors, actuators, and avionics. It synchronizes with PXI modules to simulate flight conditions, measure component responses, and validate performance. For example, when testing a pressure sensor, the controller uses a signal generator module to simulate altitude-related pressure changes, while the PXI-6251 measures the sensor’s output. The controller processes the data to verify the sensor’s accuracy and linearity across its operating range.

NI PXI-8105

5. Related Model Recommendations

PXI Chassis

The PXI-8105 is compatible with PXI chassis such as the PXI-1042 (18-slot) and PXI-1031 (3-slot). The PXI-1042 provides ample slots for multiple modules in large-scale systems, while the PXI-1031 is ideal for compact setups, such as portable test rigs. These chassis supply power to the controller and modules and facilitate backplane communication.

Data Acquisition Modules

Pair the PXI-8105 with the PXI-6251 for analog and digital data acquisition. This combination is well-suited for applications requiring measurement of multiple sensor types, such as temperature, voltage, and digital status signals. In environmental monitoring, the controller processes data from the PXI-6251 to track climate conditions in a controlled chamber.

Signal Generation Modules

For applications requiring stimulus signals, combine the PXI-8105 with a PXI-5412 arbitrary waveform generator. The controller programs the generator to produce waveforms (e.g., sine waves, pulses) and uses the PXI-6251 to measure the response of the device under test, enabling closed-loop test scenarios.

Software Tools

Enhance system functionality with NI software: LabVIEW for graphical programming of data acquisition and control logic, TestStand for test sequence management, and DIAdem for post-processing and reporting. These tools integrate seamlessly with the PXI-8105, simplifying system development and operation.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Power off the PXI chassis before installing the PXI-8105. Insert the controller into the system slot of the chassis, aligning it with the guide rails, and secure it with front panel screws. Connect peripherals (monitor, keyboard, mouse) via the I/O ports. Power on the chassis and follow the on-screen prompts to install the operating system if not pre-installed.

Commissioning Steps

Launch NI MAX to verify the controller and connected PXI modules are detected. Install NI-DAQmx and other required drivers to enable communication with modules like the PXI-6251. Configure network settings to enable communication with external devices or servers. Test system functionality by running a sample LabVIEW VI that acquires data from the PXI-6251 and displays it, ensuring proper data transfer and module control.

Maintenance Suggestions

Regularly update the controller’s operating system and drivers via NI Update Service to ensure compatibility with modules and software. Monitor hard drive health using disk utility tools; consider upgrading to an SSD for improved reliability. Clean the controller’s vents periodically to prevent dust buildup and overheating. Back up critical data and test programs to external storage or network drives. If performance degrades, check for memory issues and upgrade to 4 GB if needed.

7. Service and Guarantee Commitment

NI provides a 3-year standard warranty for the PXI-8105, covering defects in materials and workmanship. During the warranty period, NI offers technical support via online resources, email, and phone, assisting with installation, configuration, and troubleshooting. For out-of-warranty units, NI provides repair services, including component replacement and software reimaging. The controller is supported by NI’s global service network, ensuring users have access to timely assistance to minimize downtime in critical applications.