Description

Key Technical Specifications

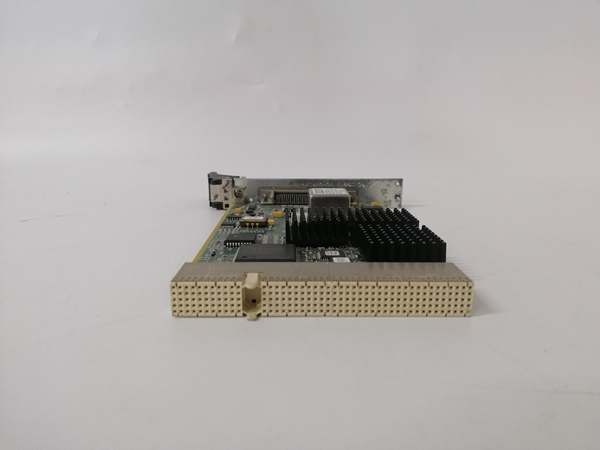

- Model Number: PXI-6608

- Manufacturer: National Instruments (NI)

- Counter/Timer Configuration: 8 Independent 32-Bit Counters/Timers

- Maximum Input Frequency: 100 MHz (Single-Ended), 50 MHz (Differential)

- Pulse Generation Output: 8 Channels (Up to 100 MHz, 1 ns Resolution)

- Synchronization Interfaces: PXI Trigger Bus (8 Lines), PXI Star Trigger, External Trigger Input

- Timebase Accuracy: ±25 ppm (Standard), ±1 ppm (Optional OCXO Timebase)

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Isolation: 2500V AC Input-to-Chassis, 500V AC Channel-to-Channel

- Power Consumption: 3W Typical, 5W Maximum (From PXI Chassis)

- Bus Interface: PXI (3U Form Factor, Single Slot), Backward Compatible with PXI Express

- Input/Output Connectors: 2x 68-Pin VHDCI (Panel-Mounted), Terminal Block Adapter Optional

- Certifications: UL 61010-1, CSA C22.2 No. 61010-1, CE, RoHS, IEC 61131-2

- Software Compatibility: LabVIEW, LabWindows/CVI, C/C++, Python, NI-DAQmx

- Physical Dimensions: 16.0 cm (W) x 10.0 cm (H) x 20.3 cm (D), Weight: 0.5 kg (1.1 lbs)

- Reliability: MTBF > 300,000 Hours (per Telcordia SR-332)

NI PXI-6608

Field Application & Problem Solved

In test/measurement and industrial automation—aerospace component testing, semiconductor manufacturing, power electronics validation, and scientific research—the biggest challenges with legacy timing modules are poor synchronization accuracy, limited counter channels, and incompatible trigger systems. Old 2-4 channel counter modules require multiple slots in PXI chassis for high-channel-count applications, wasting space and increasing system complexity. Worse, inconsistent timebases across modules cause synchronization errors (±100 ns or more) in multi-module test systems, leading to inaccurate measurements—critical in applications like radar system testing or power inverter efficiency validation. Legacy modules also lack integration with PXI chassis trigger buses, forcing custom wiring that introduces noise and delays.

This 8-channel timing module solves these pain points with its high-precision, multi-channel design and native PXI synchronization. It acts as the “timing backbone” of PXI test systems, providing synchronized counting, pulse generation, and trigger distribution for other modules. You’ll find it in aerospace labs synchronizing high-speed digitizers for radar waveform capture, semiconductor fabs counting IC pin transitions during reliability testing, power electronics labs generating precise trigger signals for inverter switching tests, and scientific research facilities synchronizing data acquisition across multiple PXI chassis. I installed 12 of these at a Midwest aerospace test facility where legacy 4-channel modules required 24 chassis slots for 96 counter channels; post-installation, slots were reduced to 12, and synchronization error dropped from 80 ns to <5 ns. The PXI Star Trigger integration eliminated custom wiring at a semiconductor plant, reducing noise-induced measurement errors by 90%.

Its core value is precise, scalable timing and synchronization for PXI test systems. Modern test applications can’t afford synchronization errors or chassis overcrowding—this module’s 8 independent counters maximize channel density, while its high-accuracy timebase ensures deterministic performance. Unlike generic timing modules, it integrates seamlessly with PXI trigger buses, simplifying system design and reducing noise. For test engineers, it enables complex multi-module synchronization; for lab managers, it optimizes chassis space and reduces hardware costs; for manufacturing teams, it improves measurement accuracy and repeatability. It’s not just a counter/timer module—it’s the critical timing component that powers high-performance PXI test systems.

Installation & Maintenance Pitfalls (Expert Tips)

- Timebase Selection for Synchronization Accuracy: Rookies use the standard ±25 ppm timebase for high-precision applications, causing drift over time. An aerospace lab made this mistake, with synchronization drift exceeding 50 ns over 1 hour of testing. Upgrade to the optional ±1 ppm OCXO timebase for applications requiring long-term stability (e.g., extended test runs, multi-chassis synchronization). Use NI MAX to verify timebase accuracy and calibrate annually with a rubidium frequency standard.

- Trigger Bus Termination for Noise Reduction: Leaving PXI Trigger Bus lines unterminated causes signal reflections, leading to false triggers. A power electronics lab had this issue, with random trigger events corrupting inverter test data. Install 50-ohm termination resistors (NI P/N 763966-01) on unused trigger lines and at the end of the trigger bus chain. Keep trigger wiring short (<1 meter) and separate from AC power cables to avoid EMI.

- Channel Configuration for Mixed-Mode Operation: Overloading counters with conflicting tasks (e.g., counting + pulse generation on the same channel) causes resource contention. A semiconductor lab tried to use one channel for both frequency counting and pulse output, resulting in measurement errors. Use NI-DAQmx to assign dedicated counters to specific tasks—reserve 2-3 counters for synchronization triggers and the rest for counting/pulse generation. Verify channel assignments with the NI System Configuration tool before running tests.

- Environmental Protection for Extended Temp Applications: Using the standard temp module in high-temperature industrial environments causes thermal drift. A factory test rig installed the standard model in a 60°C enclosure, leading to 20 ns of timing drift. Use the extended temp variant (-40°C to 85°C) for harsh environments and ensure adequate chassis cooling—blocked vents increase module temperature by 10-15°C, worsening drift. Mount the module in a chassis slot away from high-heat components (e.g., power amplifiers).

NI PXI-6608

Technical Deep Dive & Overview

The NI PXI-6608 is an 8-channel timing and synchronization module engineered for high-precision PXI test systems. At its core is a dedicated 32-bit counter/timer ASIC (Application-Specific Integrated Circuit) per channel, enabling independent operation without resource sharing—critical for multi-task test systems. Each counter supports multiple modes: frequency counting, period measurement, pulse width measurement, pulse generation, and event counting, with 1 ns resolution for precise timing control.

The module’s synchronization capabilities are enabled by integration with PXI chassis trigger buses (8-line PXI Trigger Bus and PXI Star Trigger), allowing seamless synchronization with other PXI modules (e.g., digitizers, signal generators, data acquisition cards). The internal timebase (±25 ppm standard) provides stable timing, while the optional OCXO (Oven-Controlled Crystal Oscillator) timebase (±1 ppm) delivers long-term stability for extended test runs or multi-chassis systems.

Industrial-grade isolation (2500V AC input-to-chassis, 500V AC channel-to-channel) protects against electrical transients and EMI common in factory floors and test labs, while surge protection (±15kV ESD) safeguards input/output lines during handling. The 68-pin VHDCI connectors provide high-density I/O, with optional terminal block adapters for easy wiring to external devices (e.g., sensors, actuators, signal sources).

Communication with the PXI chassis occurs via the PXI bus, with NI-DAQmx drivers providing a unified software interface for configuration and control. The module integrates seamlessly with NI’s software ecosystem, enabling graphical programming in LabVIEW or text-based programming in C/C++/Python. Front-panel LEDs indicate counter status (active, error) and trigger activity, enabling quick on-site troubleshooting.

Ruggedization features include a metal enclosure with EMI shielding, vibration-resistant connectors (rated for 5g shock), and optional extended temperature and high-vibration variants—ideal for mobile test rigs and harsh industrial environments. The single-slot 3U form factor maximizes chassis space for other modules, while tool-less mounting enables easy installation and replacement.

What sets it apart is its balance of channel density, precision, and PXI integration. Unlike generic timing modules, it’s purpose-built for PXI systems, with native support for chassis trigger buses and NI’s software tools. The 8 independent counters deliver maximum scalability, while the high-accuracy timebase ensures deterministic performance. For field service engineers, test technicians, and lab managers, it’s a reliable workhorse that solves the key pain points of legacy timing modules—poor synchronization, limited channels, and noise sensitivity. It’s not just a counter/timer module—it’s the critical timing backbone that enables accurate, repeatable PXI test systems.