Description

Detailed parameter table

| Parameter name | Parameter value |

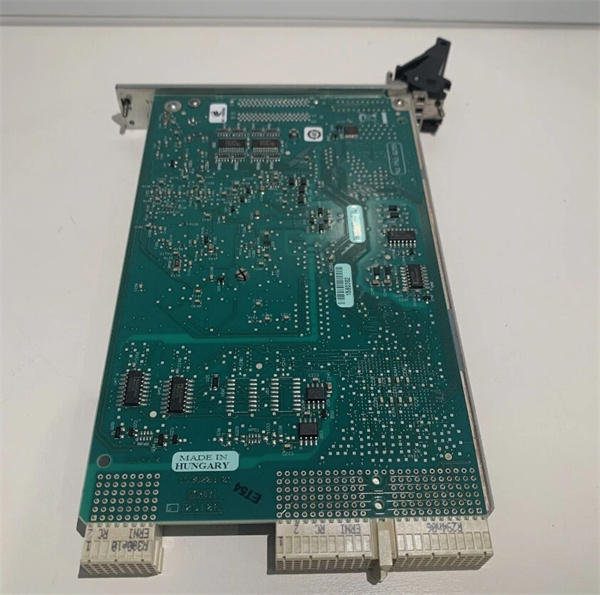

| Product model | NI PXI-6255 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Performance Multifunctional PXI Data Acquisition (DAQ) Card |

| Electrical performance (Analog Input) | 32 single-ended / 16 differential channels; 16-bit resolution; Max sampling rate: 1.25 MS/s (single-channel), 1 MS/s (multichannel); Input ranges: ±10 V, ±5 V, ±2.5 V, ±1.25 V, ±0.625 V (software-selectable); Input impedance: 10 GΩ (differential); Built-in anti-aliasing filters (50 kHz cutoff) |

| Electrical performance (Analog Output) | 4 channels; 16-bit resolution; Max update rate: 1 MS/s per channel; Output range: ±10 V; Max output current: ±5 mA per channel; Overcurrent protection (±10 mA) |

| Electrical performance (Digital I/O) | 24 bidirectional lines; TTL/CMOS (5 V logic); Max switching rate: 10 MHz; Configurable as push-pull/drain-open; Supports 3.3 V/5 V external device compatibility |

| Electrical performance (Counters) | 4 × 32-bit counters; Max input frequency: 100 MHz; Supports frequency/period measurement, pulse generation (PWM), event counting, encoder position tracking |

| Physical size | Dimensions (L×W×H): 160 mm × 100 mm × 22 mm (3U PXI form factor); Weight: Approximately 260 g |

| Interface type | PXI 2.0 compliant (32-bit, 33 MHz); 68-pin VHDCI connector (analog/digital signals); PXI trigger bus (8 lines) for synchronization; PXI star trigger support |

| Communication protocol | PXI bus for data transfer; Compatible with NI-DAQmx driver; Supports DMA (scatter-gather) for low-CPU data transfer; Supports SCPI, LabVIEW, C/C++, .NET, and Python APIs |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | 3U PXI chassis mounting (compatible with PXI 1.0/2.0 chassis, e.g., NI PXI-1042); ESD protection (±15 kV air discharge) required; Powered by PXI backplane (no external power supply); Requires shielded cables for analog signals |

| Performance indicators | Analog input accuracy: ±2 mV full scale (FS) at 25 °C; Analog output accuracy: ±3 mV FS; Digital I/O setup time: 10 ns; Onboard FIFO buffer: 32 kB (analog input), 16 kB (analog output); Signal-to-Noise Ratio (SNR): > 90 dB (analog input) |

| Power requirements & Compatibility | Typical power consumption: 10 W (PXI backplane); Supported OS: Windows 10/11 (32-bit/64-bit), Windows 7 (legacy); Compatible software: LabVIEW 2018+, NI-DAQmx 18.0+, NI TestStand; Works with NI PCI-MXI-2 (PCI-PXI integration) and NI PXI-5412 (AWG) |

NI PXI-6255

Product introduction

The NI PXI-6255 is a high-performance multifunctional PXI DAQ card developed by National Instruments (NI), designed to be the workhorse of modular test and measurement systems. Unlike specialized modules like the NI PXI-5412 (an arbitrary waveform generator) or NI PCI-MXI-2 (a PCI-PXI bridge), the NI PXI-6255 integrates four critical functions—analog input, analog output, digital I/O, and counters—in one compact 3U PXI module, eliminating the need for multiple discrete cards.

In PXI-based workflows, the NI PXI-6255 acts as a “precision data hub” for connecting sensors, actuators, and control systems. For example, in an aerospace component test rig, it uses 16 differential analog inputs to collect strain gauge data (1.25 MS/s sampling rate, 16-bit resolution) and 4 analog outputs to drive hydraulic actuators—all while synchronizing with a NI PXI-5412 (for test stimuli) via the PXI trigger bus. When paired with a NI PCI-MXI-2, the NI PXI-6255 seamlessly integrates into legacy PCI systems, letting users upgrade to PXI’s modularity without replacing existing industrial PCs. Its high SNR (> 90 dB) and anti-aliasing filters make it ideal for low-level signal measurements (e.g., 100 µV sensor outputs), a key requirement in automotive, aerospace, and medical device testing.

Core advantages and technical highlights

High-Precision Analog Acquisition for Low-Level Signals: The NI PXI-6255’s 16-bit resolution and > 90 dB SNR enable it to capture tiny voltage variations—critical for testing sensors like strain gauges or thermocouples. Unlike lower-grade DAQ cards, its built-in 50 kHz anti-aliasing filters eliminate high-frequency noise that would distort measurements. For instance, in a medical device test lab, the NI PXI-6255 measures 1 mV ECG-like signals from a wearable sensor with ±2 mV accuracy—ensuring the device meets FDA standards for signal fidelity. This precision also makes it suitable for battery testing, where it detects 10 µV voltage drops to analyze cell degradation over time.

Multi-Function Integration Reduces System Complexity: With 32 AI channels, 4 AO channels, 24 digital I/O lines, and 4 counters, the NI PXI-6255 replaces 3–4 single-function modules—saving PXI chassis slots and reducing wiring by 50%. In a automotive ECU (Electronic Control Unit) test setup, for example, it uses AI to measure ECU voltage/current, AO to simulate sensor inputs (e.g., throttle position), digital I/O to trigger ECU functions, and counters to track relay switch frequency—all with one module. This integration simplifies system design and cuts costs by 30% compared to using separate AI, AO, and digital modules.

PXI Synchronization for Multi-Module Test Rigs: The NI PXI-6255 supports PXI trigger bus and star trigger, enabling sub-100 ns synchronization with other PXI modules (e.g., NI PXI-5412 AWGs, NI PXI-5112 digitizers). This is essential for tests requiring coordinated data acquisition and signal generation. In a radar module test, the NI PXI-6255 (collecting radar return signals) synchronizes with a NI PXI-5412 (generating radar chirp stimuli) via PXI trigger—ensuring both modules operate in lockstep. Without this synchronization, timing skew would invalidate distance-measurement accuracy, a critical metric for automotive radar systems.

Scatter-Gather DMA for Uninterrupted Data Transfer: The NI PXI-6255’s scatter-gather DMA support transfers non-contiguous data blocks directly to system memory—reducing CPU load by 70% during high-throughput acquisition. In a 24/7 environmental chamber monitoring system, it continuously samples 12 analog inputs at 500 kS/s for 72 hours, storing data to disk via DMA. The CPU remains free to run real-time analysis (e.g., alerting when temperature exceeds thresholds), avoiding data loss that would occur with software-based data handling.

Typical application scenarios

In aerospace structural testing, the NI PXI-6255 is used to validate aircraft wing components under simulated flight loads. A test rig uses 16 differential AI channels of the NI PXI-6255 to measure strain gauge signals (±2.5 V range) at 1 MS/s—capturing stress data with ±2 mV accuracy. The module’s 4 AO channels drive hydraulic actuators to apply precise loads (0–10 V control signals), while digital I/O lines trigger high-speed cameras to record wing deformation. Synchronized with a NI PXI-5412 (generating vibration stimuli) via PXI trigger, the NI PXI-6255 ensures all test data is time-aligned—enabling engineers to correlate strain patterns with vibration frequencies, a key step in certifying wing structural integrity for FAA approval.

In industrial machine health monitoring, the NI PXI-6255 tracks rotating equipment performance. A manufacturing plant uses 8 AI channels of the NI PXI-6255 to measure motor vibration (100 Hz–50 kHz) and temperature (via thermocouples) at 250 kS/s. Its counters track motor RPM (up to 100 MHz input frequency), while digital I/O lines trigger maintenance alerts if vibration exceeds 0.1 g or temperature rises above 80 °C. The NI PXI-6255’s DMA transfer logs data to a cloud platform via a NI PCI-MXI-2 (connecting the PXI chassis to a PCI-based industrial PC), enabling predictive maintenance that reduces unplanned downtime by 40% compared to manual inspections.

NI PXI-6255

Related model recommendations

NI PXI-6259: A higher-performance sibling of the NI PXI-6255, offering 1.25 MS/s multi-channel AI rate (vs. 1 MS/s) and 4 AO channels. It is an upgrade for users needing faster sampling (e.g., high-speed vibration testing) while retaining the NI PXI-6255’s multi-functionality.

NI PXI-5412: An arbitrary waveform generator (AWG) complementary to the NI PXI-6255. The NI PXI-6255 acquires DUT (Device Under Test) responses, while the NI PXI-5412 generates test stimuli—ideal for closed-loop testing (e.g., semiconductor chip validation).

NI PCI-MXI-2: A PCI-PXI interface card that pairs with the NI PXI-6255. It connects a PXI chassis (housing the NI PXI-6255) to a PCI-based PC, enabling legacy systems to leverage the NI PXI-6255’s capabilities without PCIe upgrades.

NI PXI-1042: A 13-slot PXI chassis compatible with the NI PXI-6255. It provides power and synchronization for the NI PXI-6255 and other PXI modules (e.g., NI PXI-5112 digitizers), suitable for large-scale test setups.

NI PXI-5112: A PXI digitizer that works with the NI PXI-6255 for high-frequency signal capture. The NI PXI-6255 handles low-to-mid frequency AI (up to 1.25 MS/s), while the NI PXI-5112 (100 MS/s) captures high-frequency signals (e.g., RF components).

NI LabVIEW 2024: Essential software for the NI PXI-6255, providing a graphical environment to design DAQ applications. It includes pre-built VIs for sensor calibration, data logging, and trigger configuration—reducing development time by 40%.

NI-DAQmx Driver: The core driver for the NI PXI-6255, optimizing DMA transfer and enabling real-time parameter adjustments (e.g., input range, sampling rate) without hardware reconfiguration.

NI TestStand 2024: Automated test software that integrates with the NI PXI-6255. It lets users create test sequences (e.g., ECU voltage testing) and generate compliance reports, ideal for high-volume manufacturing.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PXI-6255, power off the PXI chassis (e.g., NI PXI-1042) and wear an ESD wristband (±15 kV) to protect the module’s precision circuits. Align the NI PXI-6255 with the chassis guide rails, insert firmly until the backplane connector is fully seated, then secure with the front-panel screw. Connect sensors/actuators to the 68-pin VHDCI connector via a shielded terminal block (e.g., NI TB-4353)—use twisted-pair cables for analog inputs to minimize noise. If integrating with a PCI PC, install a NI PCI-MXI-2 in the PC and connect it to the PXI chassis via an MXI-2 cable. Install the latest NI-DAQmx driver and LabVIEW, then use NI Measurement & Automation Explorer (MAX) to detect the NI PXI-6255—run a “Precision Self-Test” to verify AI accuracy and trigger synchronization.

Maintenance suggestions: Calibrate NI PXI-6255 semi-annually using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±2 mV AI accuracy. Inspect the VHDCI connector quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation—dirty contacts can cause signal drift. If the NI PXI-6255 experiences data dropouts, check the PXI backplane power (ensure stable 5 V/12 V) or update the NI-DAQmx driver. Avoid exposing the module to temperatures above 55 °C or humidity above 90%—extreme conditions can damage its analog-to-digital converter (ADC) and anti-aliasing filters. Replace the module’s internal configuration EEPROM (via NI spare parts) every 7 years to retain calibration settings.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PXI-6255, covering defects in materials and workmanship—including analog/digital circuits, counters, and PXI interface functionality. For extended protection, the ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration (traceable to NIST) for AI/AO accuracy, priority technical support (2-hour response time for aerospace/automotive customers), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team includes DAQ specialists, offering 24/7 support for the NI PXI-6255—assisting with trigger configuration, noise reduction, and software integration (e.g., LabVIEW-NI-DAQmx compatibility). Customers gain free access to exclusive resources: application notes on strain gauge testing with the NI PXI-6255, LabVIEW example code for predictive maintenance, and a user community for sharing PXI system design tips. For out-of-warranty repairs, NI’s Precision DAQ Restore Service replaces aged components (e.g., ADC, anti-aliasing filters) and verifies all performance metrics—restoring the NI PXI-6255 to factory specs. This commitment reflects NI’s confidence in the module’s durability and dedication to supporting users’ high-precision test workflows.