Description

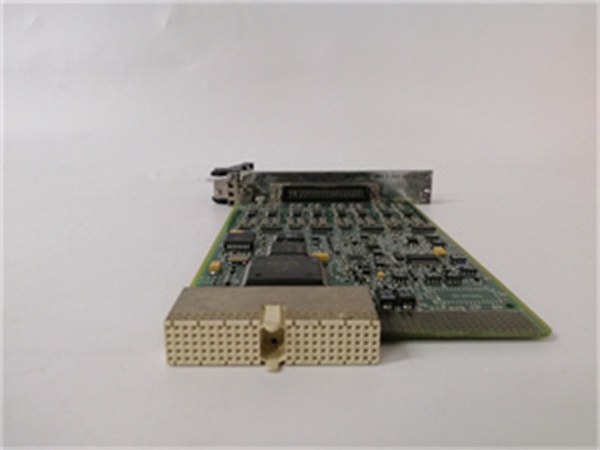

NI PXI-4351 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-4351 |

| Manufacturer | National Instruments |

| Product Category | PXI Dynamic Signal Acquisition (DSA) Module |

| Form Factor | 3U PXI |

| Slot Requirement | 1 PXI slot |

| Channels | 8 differential input channels |

| Resolution | 24 bits |

| Sampling Rate | Up to 102.4 kS/s per channel (simultaneous sampling) |

| Input Type | IEPE (Integrated Electronics Piezo-Electric) and voltage |

| Input Range (Voltage) | ±10 V, ±5 V, ±2 V, ±1 V |

| IEPE Excitation | 4 mA, 2 mA, or 0 mA (software-selectable per channel) |

| Frequency Response | DC to 40 kHz (-3 dB) |

| Dynamic Range | 118 dB (typical) |

| THD + N (Total Harmonic Distortion + Noise) | -100 dB (typical at 1 kHz) |

| CMRR (Common Mode Rejection Ratio) | >100 dB (at 50 Hz/60 Hz) |

| Input Impedance | 100 kΩ (voltage mode), 10 kΩ (IEPE mode) |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 320 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | LabVIEW, LabWindows/CVI, .NET, C/C++, NI-DAQmx |

NI PXI-4351

Product Introduction

The NI PXI-4351 is a high-performance 3U PXI dynamic signal acquisition module designed to capture high-fidelity audio and vibration signals in test and measurement applications. As a key component of National Instruments’ DSA portfolio, it combines 24-bit resolution with simultaneous sampling across 8 channels, making it ideal for applications requiring precise measurement of dynamic phenomena such as acoustic emissions, structural vibrations, and machinery health monitoring.

This module integrates seamlessly with PXI chassis like the PXI-1031, leveraging the PXI bus for synchronized operation with other modules—including the PXI-4071 DMM for multi-domain measurements. Its support for both IEPE sensors (e.g., accelerometers, microphones) and voltage inputs eliminates the need for external signal conditioning, simplifying system design. Whether deployed in automotive NVH (Noise, Vibration, Harshness) testing, aerospace structural analysis, or industrial machinery diagnostics, the PXI-4351 delivers accurate, low-noise measurements.

Core Advantages and Technical Highlights

High-Resolution Dynamic Signal Capture

With 24-bit resolution and a dynamic range of 118 dB, the PXI-4351 excels at capturing faint signals in noisy environments. This is critical for applications like acoustic testing, where subtle sound variations (e.g., in automotive cabin noise analysis) must be distinguished from background interference. The module’s low THD + N (-100 dB) ensures that harmonic distortion does not corrupt measurements, preserving signal integrity even for high-amplitude inputs.

Simultaneous Multi-Channel Sampling

The PXI-4351 samples all 8 channels simultaneously at up to 102.4 kS/s per channel, ensuring time-aligned data for phase-sensitive analysis. In structural health monitoring, for example, this capability allows engineers to correlate vibrations across different points on a bridge or aircraft wing, identifying resonance patterns or stress concentrations. Simultaneous sampling eliminates timing errors that could skew results in multi-point dynamic tests.

Integrated IEPE Support

The module’s software-selectable IEPE excitation (4 mA, 2 mA, or 0 mA) simplifies connection to piezoelectric sensors like accelerometers and microphones. This eliminates the need for external signal conditioners, reducing system complexity and cost. In machinery diagnostics, for instance, the PXI-4351 can directly interface with an array of accelerometers mounted on a motor, capturing vibration data to detect bearing wear or misalignment.

Flexible Signal Conditioning

The PXI-4351 offers programmable input ranges (±10 V to ±1 V) to accommodate signals of varying amplitudes. This versatility allows it to measure both high-voltage transients (e.g., in power system noise analysis) and low-level sensor outputs (e.g., from microphones in audio testing). The module’s high CMRR (>100 dB) further enhances performance by rejecting common-mode noise, such as 50 Hz/60 Hz power line interference.

Typical Application Scenarios

Automotive NVH Testing

In automotive development, the PXI-4351 is used to measure noise and vibration in vehicles. It captures signals from microphones placed inside the cabin and accelerometers mounted on the engine, suspension, and chassis. Engineers analyze the data to identify sources of unwanted noise (e.g., gear whine, tire hum) and optimize designs for a quieter ride. The module’s simultaneous sampling ensures that vibrations and sounds are correlated accurately, enabling root-cause analysis.

Machinery Condition Monitoring

Industrial facilities use the PXI-4351 to monitor the health of rotating equipment like motors, pumps, and turbines. By continuously sampling vibration data, the module detects early signs of failure (e.g., increased bearing vibration) before catastrophic breakdowns occur. When paired with a PXI controller, it can trigger alerts or shutdowns based on user-defined thresholds, improving maintenance efficiency and reducing downtime.

Aerospace Structural Testing

In aerospace, the PXI-4351 supports dynamic testing of aircraft components, such as wings, fuselages, and landing gear. It measures vibrations induced by wind tunnels, hydraulic shakers, or flight simulations, helping engineers validate structural integrity and fatigue resistance. The module’s high resolution ensures that even minor resonant frequencies are captured, critical for ensuring safety in extreme operating conditions.

NI PXI-4351

Related Model Recommendations

NI PXI-1031: A 5-slot PXI chassis that houses the PXI-4351 and other modules, providing a compact platform for dynamic signal acquisition systems. Its backplane enables synchronization with controllers and other instruments.

NI PXI-4071: A 6½-digit DMM that pairs with the PXI-4351 for multi-domain testing. For example, in power system analysis, the PXI-4071 measures steady-state voltages while the PXI-4351 captures transient noise, providing a complete picture of system performance.

NI PXI-8106: A PXI controller with an Intel Core i7 processor, which processes high-speed data from the PXI-4351 in real time. It runs LabVIEW-based analysis tools to compute FFTs, spectrograms, and vibration metrics.

NI Sound and Vibration Toolkit: Software that extends the PXI-4351’s capabilities with pre-built functions for frequency analysis, order tracking, and octave band measurements. It simplifies development of custom NVH or acoustics applications.

NI BNC-2140: A terminal block that provides BNC connectors for easy connection of IEPE sensors and voltage signals to the PXI-4351. It includes status LEDs and signal conditioning indicators for quick system validation.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the PXI chassis (e.g., PXI-1031). Insert the PXI-4351 into an available peripheral slot, ensuring it is fully seated in the backplane. Secure the module with front-panel screws to prevent movement during operation.

Sensor Connection: Use the BNC-2140 terminal block to connect IEPE sensors or voltage sources to the module. For IEPE sensors, ensure the correct excitation current (4 mA, 2 mA) is selected via software. Use shielded cables to minimize noise in low-level signal applications.

Software Setup: Install NI-DAQmx drivers and the Sound and Vibration Toolkit on the PXI controller. Launch NI Measurement & Automation Explorer (MAX) to verify the module is detected and configure channel settings (range, excitation, coupling).

Commissioning

Calibration Verification: Use a calibrated signal generator to inject known frequencies (e.g., 1 kHz sine waves) into the module. Verify that measurements match the input within specified tolerances, adjusting for gain or offset if necessary.

Channel Synchronization Test: Connect a common signal to all 8 channels and verify that time stamps are aligned (using NI-DAQmx synchronization tools). This ensures phase relationships between channels are preserved.

IEPE Functionality Check: Connect an IEPE accelerometer to one channel, enable 4 mA excitation, and apply a known vibration (e.g., using a shaker table). Confirm the module accurately captures the acceleration profile.

Maintenance Tips

Periodic Calibration: Calibrate the PXI-4351 annually using NI’s accredited services to maintain measurement accuracy. This is critical for compliance with ISO 17025 or automotive industry standards (e.g., ISO 10844 for NVH testing).

Sensor Care: Inspect IEPE sensor connections regularly to ensure proper excitation and signal integrity. Clean BNC connectors with isopropyl alcohol to prevent corrosion, which can introduce noise.

Environmental Protection: Operate the module within its specified temperature (0 °C to 55 °C) and humidity ranges. Avoid exposure to excessive vibration or electromagnetic fields, which can degrade performance.

Driver Updates: Keep NI-DAQmx drivers up to date to benefit from performance improvements and bug fixes. NI’s website provides the latest software releases and compatibility information.

Service and Guarantee Commitment

The NI PXI-4351 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team offers 24/7 assistance for installation, troubleshooting, and software integration via phone, email, and online resources.

NI provides accredited calibration services with traceability to NIST, ensuring the module meets published specifications. Extended warranty and calibration plans are available for customers requiring long-term support. With a focus on reliability, the PXI-4351 is engineered to deliver consistent performance in demanding dynamic signal acquisition applications, supported by NI’s commitment to quality and customer success.