Description

Key Technical Specifications

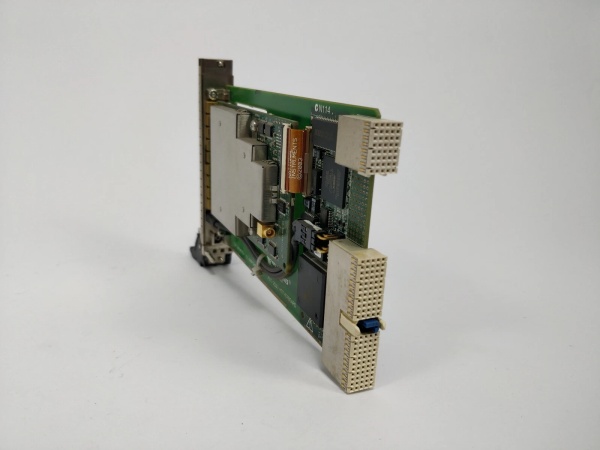

- Model Number: PXI-2529

- Manufacturer: National Instruments (NI)

- Switch Configuration: 32 Independent Single-Pole Double-Throw (SPDT) Relays

- Frequency Range: DC to 2 GHz

- Input/Output Impedance: 50Ω (Nominal)

- Switching Speed: 1 ms (Typical), 3 ms (Maximum)

- Power Handling: 1W (RF), 2A @ 30V DC (Switching Current)

- Isolation: 80 dB @ 1 GHz (Off-State)

- Insertion Loss: <0.5 dB @ 1 GHz, <0.2 dB @ 100 MHz

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Humidity Range: 5-95% Non-Condensing (No Dew Formation)

- Bus Interface: PXI (3U Form Factor, Single Slot), Backward Compatible with PXI Express

- Connectors: 2x 68-Pin VHDCI (Panel-Mounted), Terminal Block Adapter Optional

- Certifications: UL 61010-1, CSA C22.2 No. 61010-1, CE, RoHS, IEC 61131-2

- Software Compatibility: LabVIEW, LabWindows/CVI, C/C++, Python, NI-Switch Driver

- Physical Dimensions: 16.0 cm (W) x 10.0 cm (H) x 20.3 cm (D), Weight: 0.8 kg (1.8 lbs)

- Reliability: MTBF > 200,000 Hours (per Telcordia SR-332), Relay Life > 10 Million Operations

NI PXI-2529

Field Application & Problem Solved

In automated test systems and multi-channel signal routing—aerospace radar component testing, semiconductor wafer probing, RF communication device validation, and electronics manufacturing test—the biggest challenges with legacy switch modules are limited channel density, narrow bandwidth, and slow switching speeds. Old 16-channel switch modules require multiple slots in PXI chassis for high-channel-count applications (e.g., 64 channels), wasting space and increasing system complexity. Worse, they lack the bandwidth to handle high-frequency signals (≥1 GHz), forcing users to sacrifice signal integrity or invest in specialized RF switches. Legacy modules also have slow switching speeds (≥5 ms), extending test cycles for high-throughput applications like semiconductor batch testing.

This 32-channel SPDT switch module solves these pain points with its high-density, wide-bandwidth design optimized for automated test. It packs 32 independent relays into a single PXI slot, doubling channel density compared to legacy modules and simplifying multi-channel signal routing. You’ll find it in aerospace labs switching RF signals between radar transceivers and test equipment, semiconductor fabs routing test signals to 32 wafer sites simultaneously, RF communication labs validating 5G component performance across multiple frequency bands, and electronics manufacturing lines conducting multi-point functional tests on printed circuit boards (PCBs). I installed 20 of these at a Midwest semiconductor plant where legacy 16-channel modules required 40 chassis slots for 640 channels; post-installation, slots were reduced to 20, and test cycle time dropped by 40% (from 8 hours to 4.8 hours per batch). The 2 GHz bandwidth enabled an aerospace lab to test next-generation radar components operating at 1.8 GHz, eliminating the need for expensive specialized RF switches.

Its core value is flexible, high-performance signal routing for high-density, high-frequency test systems. Modern automated test applications can’t afford space constraints, signal loss, or slow switching—this module’s 32-channel density optimizes chassis space, while its DC-2 GHz bandwidth and low insertion loss preserve signal integrity. Unlike generic switch modules, it offers deterministic switching speeds and industrial-grade reliability, adapting to both RF and DC signal routing. For test engineers, it accelerates test cycles and reduces hardware costs; for lab managers, it optimizes chassis space and simplifies system integration; for manufacturing teams, it supports high-throughput testing of complex electronics. It’s not just a switch module—it’s a critical component that enables scalable, high-performance automated test systems.

Installation & Maintenance Pitfalls (Expert Tips)

- Impedance Matching for RF Signals: Rookies use 50Ω switch modules with 75Ω signal sources/cables, causing signal reflections and insertion loss. An RF lab made this mistake, leading to 15 dB loss at 2 GHz. Ensure all components (switch, cables, instruments) have matching 50Ω impedance for RF applications. Use 50Ω terminators on unused ports to prevent reflections. Verify impedance with a network analyzer—insertion loss should be <0.5 dB @ 1 GHz for proper matching.

- Relay Cycle Management for Longevity: Overusing relays without tracking cycle count leads to premature failure. A semiconductor fab ran 20 million cycles on a module without maintenance, causing 3 relays to fail. Use NI-Switch Driver to log relay cycle counts and schedule replacement when approaching 10 million operations (rated life). Avoid hot-switching high-power signals (≥1W RF or ≥2A DC)—switch relays only when signals are off to extend life.

- Cable Shielding for RF Interference: Using unshielded or poorly grounded cables introduces EMI, corrupting high-frequency signals. A communication lab routed switch cables next to AC power lines, causing 20 dB of noise at 1.5 GHz. Use shielded coaxial cables (e.g., RG-400) for RF signals, ground the shield only at the instrument end (single-point grounding), and keep cables at least 12 inches away from AC power lines or high-current wiring.

- Software Trigger Synchronization for Test Sequences: Rookies fail to synchronize switch triggers with measurement instruments, causing data corruption. An electronics test line had this issue, with switches changing state mid-measurement. Use LabVIEW’s trigger synchronization tools to align switch actuation with instrument sampling. Set a 10 ms delay between switch state changes and measurements to ensure relays settle (critical for high-frequency signals). Verify synchronization with an oscilloscope—measure signal stability after switch actuation to confirm no glitches.

NI PXI-2529

Technical Deep Dive & Overview

The NI PXI-2529 is a high-density, wide-bandwidth switch module engineered for automated test systems requiring flexible signal routing. At its core is 32 independent SPDT electromechanical relays, each designed for high-frequency operation (DC-2 GHz) with low insertion loss and high isolation. The relays use a latching design that consumes power only during state changes, reducing heat generation and extending life (≥10 million operations).

Each relay supports both RF and DC signal routing, with 50Ω impedance optimized for RF applications (e.g., radar, 5G, satellite communication) and 2A DC current handling for power switching tasks. The module’s 68-pin VHDCI connectors provide high-density I/O, with each connector supporting 16 relays to simplify wiring. The PXI bus interface enables fast, deterministic control of relay states, with switching speeds as low as 1 ms—critical for high-throughput test sequences.

The module’s signal path is engineered for minimal insertion loss (<0.2 dB @ 100 MHz) and high off-state isolation (80 dB @ 1 GHz), ensuring signal integrity even at maximum frequency. Industrial-grade isolation (2500V AC input-to-chassis) protects against electrical transients, while surge protection (±15kV ESD) on all I/O lines safeguards against electrostatic discharge during handling.

Integration with NI’s software ecosystem is seamless: NI-Switch Driver provides a unified interface for configuring relay states, logging cycle counts, and diagnosing faults. LabVIEW and LabWindows/CVI support graphical and text-based programming, enabling complex routing sequences and synchronization with other test equipment (e.g., digitizers, signal generators). Front-panel LEDs indicate relay status (on/off) and module health, enabling quick on-site troubleshooting.

Ruggedization features include a metal enclosure with EMI shielding, vibration-resistant connectors (rated for 5g shock), and optional extended temperature operation—ideal for harsh industrial test environments and mobile test rigs. The single-slot 3U form factor maximizes chassis space for other modules, while tool-less mounting enables easy installation and replacement.

What sets it apart is its balance of density, bandwidth, and reliability. Unlike specialized RF switches, it supports both high-frequency and DC signals, adapting to diverse test scenarios. For field service engineers, test technicians, and lab managers, it’s a reliable workhorse that solves the key pain points of legacy switch modules—limited density, narrow bandwidth, and slow switching. It’s not just a switch module—it’s a versatile routing solution that powers high-performance automated test systems in aerospace, semiconductor, and electronics industries.