Description

Detailed parameter table

| Parameter name | Parameter value |

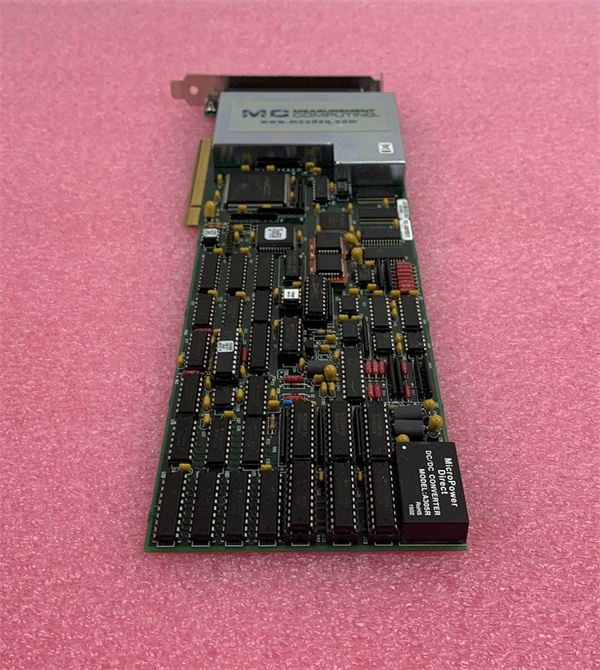

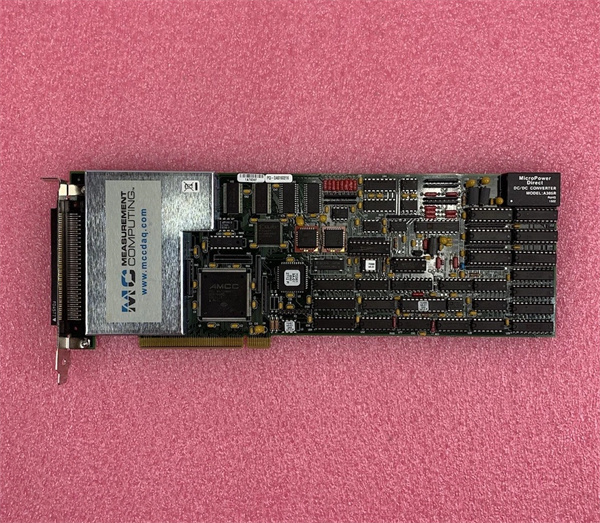

| Product model | NI PCIM-DAS160216 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy Multifunctional Data Acquisition (DAQ) Card (PCI Interface) |

| Electrical performance (Analog Input) | 16 single-ended / 8 differential channels; 12-bit resolution; Max sampling rate: 100 kS/s (single-channel), 50 kS/s (multichannel); Input ranges: ±0.5 V, ±1 V, ±2.5 V, ±5 V, ±10 V (software-selectable); Input impedance: 10 GΩ (differential) |

| Electrical performance (Analog Output) | 2 channels; 12-bit resolution; Max update rate: 10 kS/s per channel; Output range: ±10 V; Max output current: ±5 mA per channel |

| Electrical performance (Digital I/O) | 16 bidirectional lines (8 input/8 output, configurable); TTL/CMOS (5 V logic); Max switching rate: 1 MHz; Sink/source current: 24 mA per line |

| Electrical performance (Counters) | 2 × 16-bit up/down counters; Max input frequency: 1 MHz; Supports event counting, frequency measurement, pulse generation |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 210 g |

| Interface type | PCI 2.2 compliant (32-bit, 33 MHz); 68-pin SCSI-II connector (analog/digital signals); 10-pin header (external trigger/synchronization); Optional RTSI bus connector (for multi-device sync) |

| Communication protocol | PCI bus (up to 132 MB/s bandwidth); Compatible with Traditional NI-DAQ (Legacy) and NI-DAQmx (limited support); Supports DMA for low-CPU data transfer; Supports C/C++, LabVIEW, and Visual Basic APIs |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply); Requires shielded cables for analog signals |

| Performance indicators | Analog input accuracy: ±0.05% full scale (FS) at 25 °C; Analog output accuracy: ±0.1% FS; Digital I/O setup time: 15 ns; Onboard FIFO buffer: 4 kB (analog input); Signal-to-Noise Ratio (SNR): > 75 dB (analog input) |

| Power requirements & Compatibility | Typical power consumption: 7 W; Supported OS: Windows 7 (32-bit), Windows XP (legacy); Compatible software: LabVIEW 2017+ (legacy mode), Traditional NI-DAQ, C/C++ compilers |

NI PCIM-DAS160216

Product introduction

The NI PCIM-DAS160216 is a legacy multifunctional data acquisition (DAQ) card developed by National Instruments (NI), designed for mid-speed mixed-signal tasks in industrial automation, academic research, and small-scale test systems. Unlike modern PCIe-based cards like the NI PCIe-6323, the NI PCIM-DAS160216 operates on the PCI bus—making it an ideal replacement or expansion for legacy systems where PCI slots are still in use and upgrading to PCIe is cost-prohibitive.

In automation workflows, the NI PCIM-DAS160216 acts as a “workhorse data hub” for connecting legacy sensors and actuators. For example, in a decades-old manufacturing line with PCI-equipped industrial PCs, it uses 8 differential analog inputs to monitor temperature and pressure (sampling at 50 kS/s), 2 analog outputs to adjust old-style pneumatic valves, and 8 digital I/O lines to interface with legacy limit switches. Its 12-bit resolution and 100 kS/s max sampling rate strike a balance between performance and cost, making it a reliable choice for applications that don’t require the higher speed or precision of the NI PCIe-6323.

Core advantages and technical highlights

Legacy System Compatibility: The NI PCIM-DAS160216’s PCI 2.2 interface is its key advantage—directly supporting industrial PCs and automation systems built around PCI slots, which remain common in manufacturing facilities with long equipment lifecycles. Unlike the NI PCIe-6323 (which requires PCIe slots), the NI PCIM-DAS160216 drops into existing PCI chassis without hardware modifications. For instance, a food processing plant using a 15-year-old PCI-based PLC can add the NI PCIM-DAS160216 to expand sensor monitoring capacity, avoiding a $10,000+ upgrade to a new PCIe-based control system.

Balanced Functionality for Cost-Sensitive Tasks: With 16 analog inputs, 2 analog outputs, 16 digital I/O lines, and 2 counters, the NI PCIM-DAS160216 delivers all essential DAQ functions at a lower price point than modern cards. Its 12-bit resolution and 100 kS/s sampling rate are sufficient for non-critical industrial tasks (e.g., room temperature monitoring, low-speed motor control) and academic labs teaching basic DAQ principles. A community college, for example, uses the NI PCIM-DAS160216 in its automation program to teach students how to connect thermocouples (analog input) and control LEDs (digital output)—providing hands-on experience without the cost of the NI PCIe-6323.

Proven Reliability for Long-Term Use: As a legacy NI product, the NI PCIM-DAS160216 has a track record of durability in harsh industrial environments. Its rugged design (50 g shock resistance, 0–55 °C operating range) ensures stable performance in factories with vibration or temperature fluctuations. Unlike generic third-party DAQ cards, the NI PCIM-DAS160216 is backed by NI’s rigorous testing—many units have operated continuously for 10+ years in industrial settings. A water treatment plant, for instance, relies on the NI PCIM-DAS160216 to monitor chemical levels 24/7, with minimal downtime over 8 years of use.

Flexible Software Support for Legacy Workflows: The NI PCIM-DAS160216 works with Traditional NI-DAQ (legacy driver) and limited NI-DAQmx support, ensuring compatibility with existing software written for older NI DAQ cards. This is critical for users who have invested in custom LabVIEW or C/C++ code for legacy systems—they can deploy the NI PCIM-DAS160216 without rewriting code. For example, a pharmaceutical manufacturer uses the NI PCIM-DAS160216 with a 10-year-old LabVIEW program to log cleanroom humidity data, avoiding the time and cost of redeveloping the application for the NI PCIe-6323.

Typical application scenarios

In legacy industrial monitoring, the NI PCIM-DAS160216 is used for small-scale chemical processing. A specialty chemical plant with a PCI-based control system uses 8 analog inputs of the NI PCIM-DAS160216 to measure pH (±2.5 V range) and chemical concentration (±5 V range) at 50 kS/s, ensuring reactions stay within safety limits. The card’s 2 analog outputs adjust reagent pump speeds (±10 V control signals), while 4 digital I/O lines trigger audible alarms if values exceed thresholds. DMA transfer logs data to a local server, enabling compliance with FDA guidelines for batch tracking—all without upgrading the plant’s existing PCI infrastructure.

In academic education, the NI PCIM-DAS160216 supports basic DAQ training. A university’s electrical engineering department uses the card in its introductory automation course: students connect a thermistor (analog input) to measure temperature changes when a resistor is heated, use a digital output line to turn a fan on/off, and use a counter to track fan rotations. The NI PCIM-DAS160216’s simplicity and low cost let the department deploy 15 units across lab workstations, teaching 200+ students per year how to collect, analyze, and act on sensor data—preparing them for real-world automation roles.

In retrofitted commercial HVAC systems, the NI PCIM-DAS160216 enhances monitoring capabilities. A shopping mall with a 20-year-old HVAC system (controlled by a PCI-based PC) adds the NI PCIM-DAS160216 to monitor 12 zone temperatures (analog input, ±10 V range) and control 2 damper positions (analog output). The card’s digital I/O lines interface with existing HVAC relays to turn fans on/off, while its counters track runtimes for maintenance scheduling. This retrofit costs 70% less than replacing the entire HVAC control system, extending the system’s life by 5+ years.

NI PCIM-DAS160216

Related model recommendations

NI PCIe-6323: The modern PCIe successor to the NI PCIM-DAS160216, offering faster sampling (250 kS/s vs. 100 kS/s), 16-bit resolution (vs. 12-bit), and PCIe connectivity. It is recommended for users upgrading from legacy PCI systems to modern hardware.

NI PCI-DAS1602/12: A lower-resolution sibling of the NI PCIM-DAS160216, with 12-bit analog input (same as NI PCIM-DAS160216) but fewer features. It is a cost-effective alternative for basic analog input tasks (e.g., simple temperature logging).

NI PCI-6534: A high-speed digital I/O card complementary to the NI PCIM-DAS160216. The NI PCIM-DAS160216 handles analog tasks, while NI PCI-6534 (100 MHz digital I/O) adds high-speed digital control for legacy test fixtures.

NI PCI-6601: A counter/timer card that enhances the NI PCIM-DAS160216’s counting capabilities. While NI PCIM-DAS160216 has 2×16-bit counters, NI PCI-6601 (8×24-bit counters, 80 MHz) suits high-frequency event tracking (e.g., legacy motor RPM monitoring).

NI TB-2707: A shielded terminal block for the NI PCIM-DAS160216, offering 68-pin SCSI-II connectivity and surge protection. It simplifies wiring of sensors/actuators and reduces noise in industrial environments.

NI LabVIEW 2017: Legacy LabVIEW version compatible with the NI PCIM-DAS160216’s Traditional NI-DAQ driver. It lets users build basic DAQ applications for the card, ideal for educational or simple industrial use cases.

NI PCI-6259: A high-performance PCI DAQ card and upgrade of the NI PCIM-DAS160216, offering 16-bit resolution, 1.25 MS/s sampling rate, and more digital I/O lines. It is recommended for users needing better performance but staying with PCI slots.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCIM-DAS160216, power off the legacy PCI-based industrial PC and confirm an empty PCI 2.1/2.2/2.3 slot. Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s analog circuits. Insert NI PCIM-DAS160216 firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. Connect sensors/actuators to the 68-pin SCSI-II connector via NI TB-2707 terminal block—use twisted-pair shielded cables for analog inputs to reduce noise from legacy industrial equipment. Install Traditional NI-DAQ (or compatible NI-DAQmx version), then use NI Measurement & Automation Explorer (MAX) to detect NI PCIM-DAS160216 and run a self-test (verifying analog/digital/counter functions).

Maintenance suggestions: Calibrate NI PCIM-DAS160216 annually using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±0.05% FS analog accuracy. Inspect the 68-pin connector quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or industrial debris. If NI PCIM-DAS160216 experiences data dropouts, check the PCI slot for corrosion (common in older PCs) and clean with a dry brush. Avoid exposing the card to humidity above 90%—moisture can damage legacy digital I/O circuits. Replace the card’s internal configuration battery (available via NI’s legacy spare parts program) every 5 years to retain calibration settings during power outages.

Service and guarantee commitment

National Instruments (NI) provides a 1-year standard warranty for new NI PCIM-DAS160216 units (limited stock for legacy products), covering defects in materials and workmanship—including analog/digital circuits, PCI interface, and counter functionality. For extended protection, NI offers a Legacy Support Plan that extends coverage to 3 years, including technical support for Traditional NI-DAQ and expedited repairs (parts subject to availability).

NI’s legacy technical team offers specialized support for NI PCIM-DAS160216, assisting with driver installation (for older OS), software compatibility, and troubleshooting (e.g., resolving legacy PCI bus conflicts). Customers gain access to archived resources: legacy application notes on NI PCIM-DAS160216 integration, Traditional NI-DAQ user guides, and a community forum for sharing legacy DAQ best practices. For out-of-warranty repairs, NI’s Legacy Restore Service (when parts are available) restores NI PCIM-DAS160216 to factory specs—replacing aged components (e.g., analog amplifiers) and verifying 12-bit resolution. This commitment reflects NI’s dedication to supporting users with legacy automation systems who rely on the NI PCIM-DAS160216 for critical operations.