Description

Key Technical Specifications

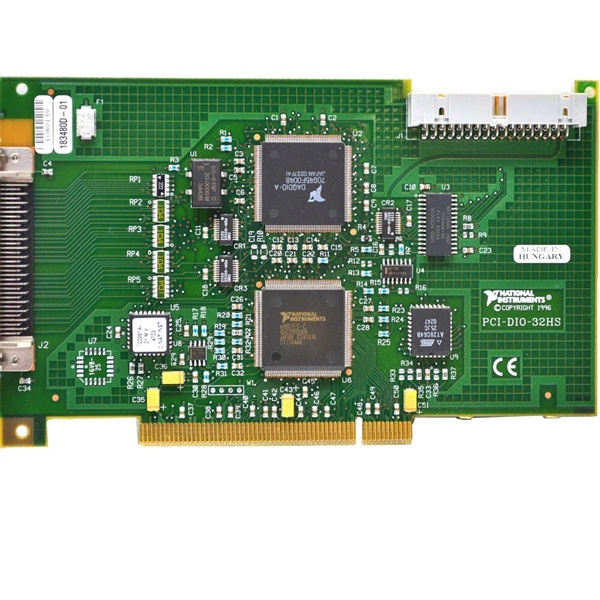

- Model Number: PCI-DIO-32HS

- Manufacturer: National Instruments (NI)

- Digital I/O Channels: 32 Bidirectional Lines (Configurable as 2×16-Bit Ports or 4×8-Bit Ports)

- I/O Speed: Up to 10 MHz (Single Channel), 5 MHz (All Channels Synchronous)

- Voltage Compatibility: 5V TTL/CMOS (VIL=0.8V Max, VIH=2.0V Min; VOL=0.4V Max, VOH=2.4V Min)

- Current Drive: 24 mA Sink/Source per Channel (Maximum)

- Bus Interface: 32-Bit PCI (33 MHz), Plug-and-Play Compliant

- Data Transfer: Direct Memory Access (DMA) + Programmed I/O (PIO)

- On-Board Memory: 8 KB FIFO per Port (32 KB Total)

- Connectors: 2×50-Pin Male Ribbon Cable Connectors (Port 0/Port 1)

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Power Consumption: 6W Typical, 9W Maximum (From PCI Bus)

- Isolation: 2500V AC Input-to-Chassis Isolation

- Software Compatibility: NI-DAQmx Driver, LabVIEW, LabWindows/CVI, C/C++, Python, Windows 2000/XP/Vista/7/10 (32/64-Bit)

- Protection Features: Overcurrent Protection (Auto-Recovery), ESD Protection (±15kV Human Body Model)

NI PCI-DIO-32HS

Field Application & Problem Solved

In high-speed industrial and test environments—electronics manufacturing, aerospace component testing, and defense systems—standard digital I/O cards can’t keep up with the demand for fast, synchronous data transfer. Legacy solutions suffer from CPU bottlenecks, limited I/O rates, or poor synchronization, leading to test failures or production delays. For example, an electronics factory testing semiconductor chips needs to generate 10 MHz digital patterns to stimulate IC pins and capture responses in real time, but low-speed I/O cards cause timing errors that misclassify good parts as defective.

This high-speed PCI digital I/O card solves those pain points with 10 MHz I/O rates, DMA transfer, and synchronous channel operation. You’ll find it in semiconductor test labs generating high-frequency digital stimuli, aerospace facilities controlling fast-acting valves and actuators, and defense systems synchronizing sensor data capture. It’s also a critical component in legacy ATE systems, where it provides the high-speed I/O needed to maintain compatibility with older test fixtures without replacing entire setups.

Its core value is speed and determinism for time-critical tasks. The 10 MHz single-channel rate and 5 MHz synchronous rate ensure precise timing for high-speed tests, while DMA transfer offloads data processing from the CPU—eliminating latency and ensuring consistent performance. For test engineers, this means reliable, repeatable results; for plant managers, it translates to reduced scrap and improved production throughput in high-volume manufacturing.

Installation & Maintenance Pitfalls (Expert Tips)

- Cable Length Limits for High-Speed Signals: At 10 MHz, signal integrity degrades rapidly with cable length—exceeding 1 meter causes reflections and timing jitter. Use shielded, twisted-pair ribbon cables and keep runs under 0.5 meters for critical applications. I’ve seen a semiconductor lab use 2-meter cables, leading to 20% test failure rates; switching to 0.3-meter shielded cables resolved the issue. For longer runs, use signal buffers or line drivers—don’t compromise on cable quality.

- Ignoring Synchronous vs. Asynchronous Mode: Rookies often assume all channels operate at 10 MHz simultaneously—this is only true for asynchronous mode. In synchronous mode (all channels triggered together), the max rate drops to 5 MHz. Verify mode settings in NI MAX before deployment—using synchronous mode at 10 MHz causes data corruption. A defense contractor’s sensor synchronization failed until they adjusted the mode to match the 5 MHz synchronous rate.

- Overcurrent Damage from Direct Load Driving: The 24 mA per channel drive is for logic-level signals—connecting relays, motors, or LEDs directly burns out I/O lines. Use opto-isolators or relay drivers for loads >5 mA. An aerospace facility fried 8 channels by powering 30 mA indicator LEDs; adding a $5 opto-isolator module prevented further damage and downtime.

- Outdated NI-DAQmx Drivers Limit High-Speed Functionality: Legacy drivers (pre-17.0) don’t support DMA for high-speed transfers, forcing the card to use PIO mode (slower and CPU-intensive). Update to NI-DAQmx 18.0+—it unlocks full DMA performance and fixes timing resolution bugs. A semiconductor factory’s test throughput doubled after updating drivers, as the card shifted from 2 MHz (PIO) to 10 MHz (DMA) operation.

NI PCI-DIO-32HS

Technical Deep Dive & Overview

The PCI-DIO-32HS’s high-speed performance is rooted in its dedicated digital I/O controller and DMA architecture. The controller features hardware-based timing and synchronization, enabling precise control of signal edges down to 100 ns (10 MHz). This is critical for applications like IC testing, where nanosecond-level timing accuracy determines test validity.

The 32 channels are split into two 16-bit ports (Port 0/Port 1) or four 8-bit ports, configurable via software to match application needs. Each port includes an 8 KB FIFO buffer, which stores data before DMA transfer to the host PC—preventing underruns/overruns during high-speed acquisition or generation. DMA transfer bypasses the CPU, ensuring deterministic data flow even at maximum rates, a key advantage over low-cost I/O cards that rely on CPU-intensive PIO.

Isolation (2500V AC) and ESD protection (±15kV) make the card rugged enough for industrial environments, where voltage transients and electrostatic discharge are common. The overcurrent protection on each channel automatically shuts down the line if current exceeds 24 mA, preventing permanent damage from wiring errors or load faults.

While the PCI bus is aging, its 132 MB/s bandwidth is sufficient for the card’s maximum data rate (32 channels × 5 MHz × 1 bit = 20 MB/s), ensuring no bottlenecks. The card’s software compatibility with LabVIEW and NI-DAQmx provides a familiar interface for test engineers, enabling rapid development of custom digital patterns and control sequences.

For field engineers and test technicians, the PCI-DIO-32HS’s biggest strength is its reliability at high speeds. It’s a purpose-built tool for time-critical digital I/O tasks, delivering consistent performance in harsh industrial and test environments. While newer PCIe cards offer higher bandwidth, the PCI-DIO-32HS remains a trusted workhorse in legacy systems and applications where 10 MHz performance is sufficient—proven by its decades-long track record in aerospace, defense, and electronics manufacturing.