Description

Detailed parameter table

| Parameter name | Parameter value |

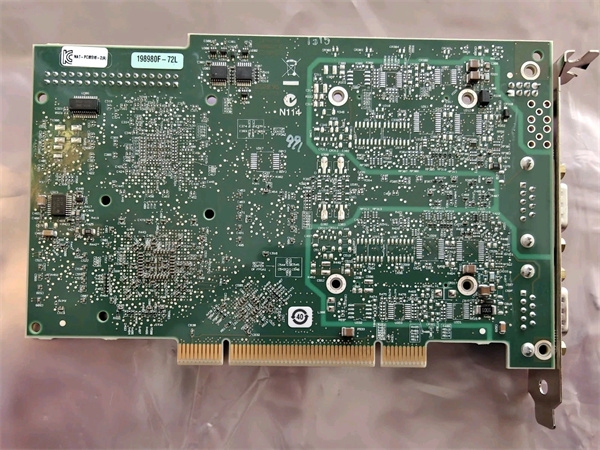

| Product model | PCI-8516 |

| Manufacturer | National Instruments (NI) |

| Product category | PCI-Based CAN/LIN Interface Card |

| Electrical performance | Power supply: +5V DC (from PCI bus); Current consumption: Max 120 mA; CAN bus termination: Selectable 120Ω resistor per channel |

| Physical size | Form factor: 32-bit/33 MHz PCI (half-length); Dimensions: 146 mm × 107 mm (5.75 in × 4.21 in); Weight: ~100 g (0.22 lbs) |

| Interface type | 2 x CAN/LIN channels (isolated); DB9 connectors (male) for CAN/LIN bus; Internal PCI interface for host PC communication |

| Communication protocol | CAN 2.0A (11-bit ID) / 2.0B (29-bit ID); LIN 1.3/2.0/2.1; Support for CAN FD (optional via firmware update for select versions); Compatible with CANopen, DeviceNet, J1939 protocols |

| Environmental requirements | Operating temperature: 0°C to 55°C (32°F to 131°F); Storage temperature: -20°C to 70°C (-4°F to 158°F); Relative humidity: 10% to 90% (non-condensing); Vibration: 5 g rms (10 Hz to 500 Hz) |

| Installation method | 32-bit PCI slot (33 MHz) in industrial PCs/servers; Requires NI-DAQmx or NI-CAN software for configuration |

| Performance indicators | Data transfer rate: CAN: Up to 1 Mbps; LIN: Up to 20 kbps; Message buffer: 8 kB FIFO per channel (transmit/receive); Timestamp resolution: 1 µs; Isolation voltage: 250 Vrms (channel-to-channel, channel-to-ground) |

| Compatibility | Supported OS: Windows 10/11 (64-bit), Windows Server 2019/2022; Compatible with NI LabVIEW, LabWindows/CVI, C/C++, Python (via NI-DAQmx API) |

| Safety certifications | CE, FCC Class A, UL/cUL 61010-1 (for industrial control equipment); RoHS compliant |

| Additional features | Hot-swap support (with compatible PCI slots); LED status indicators (power, CAN/LIN bus activity, error); Integrated bus fault protection (overvoltage/short-circuit) |

NI PCI-8516

Product introduction

The PCI-8516 from National Instruments (NI) is a high-performance PCI-based CAN/LIN interface card, engineered to enable reliable communication between industrial PCs and CAN/LIN networks. As a key component of NI’s industrial communication portfolio, it bridges the gap between host computing systems and embedded CAN/LIN devices—such as automotive ECUs, industrial sensors, and control modules—making it ideal for test, measurement, and automation applications.

Designed for flexibility, the PCI-8516 supports both CAN (2.0A/2.0B) and LIN (1.3/2.0/2.1) protocols, allowing it to integrate with legacy and modern embedded systems. In automotive development, for example, it enables engineers to monitor and control CAN-based powertrain modules or LIN-based body electronics. For industrial automation, it facilitates data exchange between PLCs and CANopen-enabled actuators. By leveraging NI’s intuitive software tools (e.g., LabVIEW), the PCI-8516 simplifies configuration, data logging, and real-time analysis, empowering users to build custom test benches or automation workflows with minimal coding.

Core advantages and technical highlights

Isolated channels for robust operation

The PCI-8516 features 250 Vrms isolation per channel, protecting both the card and host PC from electrical noise, ground loops, and voltage spikes common in industrial/automotive environments. In automotive manufacturing plants—where machinery generates heavy electromagnetic interference (EMI)—this isolation ensures uninterrupted CAN/LIN communication, preventing data corruption or hardware damage. For example, when testing electric vehicle (EV) battery management systems (BMS), the PCI-8516’s isolation shields the test PC from high-voltage transients, ensuring safe and accurate data collection.

Dual CAN/LIN channels for multi-network support

With two independent CAN/LIN channels, the PCI-8516 enables simultaneous communication with separate networks—eliminating the need for multiple interface cards. In a smart factory, this means one card can connect to a CAN-based motor control network and a LIN-based sensor network, streamlining system architecture and reducing PC slot usage. The channels also support mixed-mode operation (e.g., one CAN, one LIN), making the PCI-8516 versatile for applications like automotive infotainment testing, where both protocols are used.

High-speed data handling and precise timing

The PCI-8516 delivers CAN data rates up to 1 Mbps and 1 µs timestamp resolution, critical for time-sensitive applications like real-time control or event logging. In aerospace testing, for instance, it can capture and timestamp CAN messages from flight control systems with microsecond accuracy, enabling engineers to correlate events (e.g., sensor readings, actuator commands) for post-test analysis. The 8 kB FIFO buffers per channel prevent data loss during high-traffic periods, ensuring no critical messages are dropped—even when the host PC is busy processing other tasks.

Easy software integration with NI ecosystems

The PCI-8516 is fully compatible with NI’s software suite, including LabVIEW, LabWindows/CVI, and the NI-CAN API. This integration reduces development time: users can drag-and-drop CAN/LIN functions in LabVIEW to build custom dashboards, automate test sequences, or log data to databases. For example, a automotive engineer can use LabVIEW to create a real-time monitoring tool that displays CAN bus traffic from the PCI-8516 and triggers alerts for error frames. The card also supports third-party tools (e.g., Python, C/C++) via NI-DAQmx, ensuring compatibility with existing workflows.

Typical application scenarios

Automotive ECU Testing

In automotive engineering, the PCI-8516 is a staple for ECU (Electronic Control Unit) validation. For powertrain ECUs, it connects to the CAN bus to send/receive control commands (e.g., fuel injection timing) and log sensor data (e.g., engine temperature). For body electronics (e.g., door locks, lighting), it uses LIN to simulate user inputs and verify ECU responses. During end-of-line testing, the PCI-8516 automates test sequences—such as checking if the ECU correctly processes CAN messages from the BMS—reducing manual effort and ensuring consistent results across production lines.

Industrial Automation Control

In smart manufacturing, the PCI-8516 enables industrial PCs to communicate with CANopen-enabled devices (e.g., servo drives, variable-frequency drives). For a robotic assembly line, it sends CAN messages to control robot joint positions and receives feedback (e.g., torque, speed) for closed-loop control. The card’s isolation protects the PC from noise generated by motors, ensuring reliable communication even in harsh factory environments. Additionally, its LIN support allows integration with low-cost sensors (e.g., proximity sensors) for status monitoring, creating a unified control system.

Aerospace/Defense Embedded Systems

In aerospace applications, the PCI-8516 is used to test and monitor CAN-based avionics systems (e.g., flight control, navigation). During ground testing, it connects to the aircraft’s CAN bus to simulate sensor data (e.g., altitude, airspeed) and validate how the flight controller responds. The card’s precise timestamping helps engineers analyze latency between command issuance and actuator response, critical for ensuring system safety. Its rugged design (wide temperature range, vibration resistance) also makes the PCI-8516 suitable for field testing in harsh environments.

NI PCI-8516

Related model recommendations

NI PCI-8512

A single-channel CAN interface card, serving as a cost-effective alternative to the PCI-8516 for applications needing only CAN (no LIN). Ideal for simple CAN networks (e.g., industrial sensor monitoring) where dual channels are unnecessary.

NI PCI-8513

Dual-channel CAN FD interface card—an upgrade from the PCI-8516 for high-speed CAN FD networks (up to 8 Mbps). Suitable for modern automotive/EV testing, where CAN FD is used for high-bandwidth data (e.g., EV battery telemetry).

NI USB-8502

USB-based CAN/LIN interface (instead of PCI), offering portability for field testing. Complements the PCI-8516 for scenarios where a PC with a PCI slot is unavailable (e.g., on-vehicle diagnostics).

NI cRIO-9853

CompactRIO-based CAN module, designed for embedded systems (not PC-based). Works with the PCI-8516 in hybrid setups—e.g., the PCI-8516 logs data in a lab, while the cRIO-9853 controls CAN devices in a field-deployed system.

NI PCIe-8522

PCI Express (PCIe) version of the PCI-8516, offering faster host PC communication (via PCIe 1x) and higher bandwidth. Recommended for high-traffic networks (e.g., automotive ADAS testing) where PCI bus speed is a bottleneck.

NI 9850

C Series CAN module for NI CompactDAQ chassis. Paired with the PCI-8516, it extends CAN/LIN connectivity to distributed measurement systems (e.g., monitoring multiple CAN buses across a factory floor).

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the PCI-8516, power off the host PC and ground yourself to avoid electrostatic discharge (ESD). Ensure the PC has an available 32-bit/33 MHz PCI slot (half-length compatible). Remove the PC’s side panel, align the PCI-8516 with the slot, and press firmly until it seats. Secure the card with a screw to prevent vibration damage. Connect CAN/LIN devices to the DB9 ports—use twisted-pair cables for optimal noise immunity, and enable the 120Ω termination resistor if the card is at the end of the bus. Install NI-CAN software (from NI’s website) and restart the PC to detect the card automatically.

Maintenance suggestions

For long-term performance, inspect the PCI-8516 quarterly: check for loose DB9 connections, dust accumulation on the card (clean with compressed air), and LED status (steady green = normal, flashing red = error). If communication fails, verify the CAN/LIN bus wiring (ensure no short circuits) and update the NI-CAN firmware via NI Package Manager. Replace damaged DB9 cables immediately to avoid signal degradation. Store spare PCI-8516 cards in ESD-safe packaging, and only use NI-certified replacement parts (e.g., fuses) to maintain compliance with safety standards.

Service and guarantee commitment

NI backs the PCI-8516 with a 2-year standard warranty, covering defects in materials and workmanship. For extended protection, customers can purchase NI’s ServicePlus plan, which includes 3–5 years of warranty, priority technical support, and firmware updates. NI’s global support team (available 24/7 via email, phone, and online chat) provides assistance with installation, troubleshooting, and software integration—including custom code examples for LabVIEW. If a PCI-8516 fails within the warranty period, NI offers fast replacement (next-business-day shipping for critical applications) to minimize downtime. This commitment reflects NI’s confidence in the PCI-8516’s durability and its dedication to customer success in test and automation projects.