Description

Key Technical Specifications

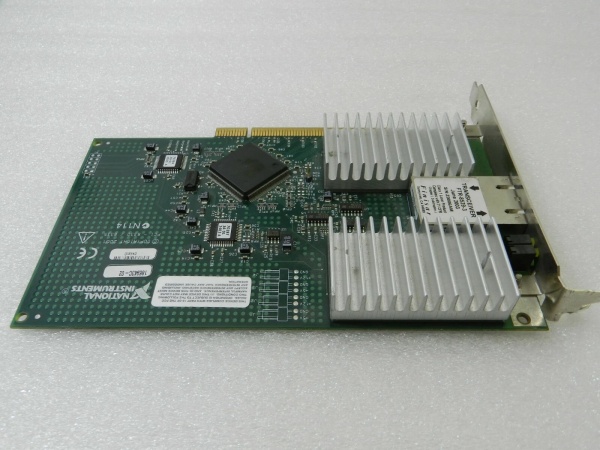

- Model Number: PCI-8330

- Manufacturer: National Instruments (NI)

- CAN Protocol Support: ISO 11898-2 (High-Speed CAN), ISO 11898-3 (Low-Speed CAN), LIN 2.0

- Number of Ports: 4 Independent CAN/LIN Ports (Software-Configurable)

- Max Bit Rate: 1 Mbps (High-Speed CAN), 125 kbps (Low-Speed CAN)

- Bus Interface: 32-Bit PCI (33 MHz), Plug-and-Play Compliant

- Transceiver Type: Integrated CAN Transceivers (Isolated)

- Isolation: 2500V AC Port-to-Chassis Isolation

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Power Consumption: 7W Typical, 10W Maximum (From PCI Bus)

- Connectors: 4×9-Pin D-Sub (DB-9) Female Connectors

- Software Compatibility: NI-CAN Driver, LabVIEW, LabWindows/CVI, C/C++, Python, Windows 2000/XP/Vista/7 (32/64-Bit)

- Error Handling: Built-in CAN Error Detection (Bit Error, Stuff Error, CRC Error), Automatic Bus Recovery

NI PCI-8330

Field Application & Problem Solved

In industrial settings—automotive assembly lines, power plant control rooms, manufacturing facilities—CAN bus networks are the backbone of device communication, but connecting these networks to modern PCs or test systems is a persistent headache. Legacy CAN interfaces often have limited ports, poor isolation, or lack compatibility with industrial protocols, forcing engineers to use multiple single-port cards that clutter chassis and create synchronization issues. In automotive ECU testing, for example, technicians need to monitor 4+ CAN buses simultaneously (engine, transmission, infotainment) but struggle with unsynchronized data capture or signal interference from harsh factory environments.

This 4-port CAN interface card solves those problems by packing independent, isolated CAN ports into a single PCI slot. You’ll find it in automotive test labs validating ECU communication across multiple CAN networks, power plants integrating legacy CAN-based sensors with SCADA systems, and manufacturing lines syncing PLCs, motors, and actuators via CAN. It’s also a staple in legacy system upgrades—when replacing outdated controllers, it provides a direct path to connect existing CAN devices without rewiring entire networks.

Its core value is reliability and scalability in harsh conditions. The 2500V isolation protects against voltage transients common in industrial environments, while four independent ports eliminate the need for multiple cards, reducing failure points. For field engineers, this means simplified setup, synchronized data capture, and reduced downtime—critical in 24/7 operations where even a minor communication fault can halt production.

Installation & Maintenance Pitfalls (Expert Tips)

- Termination Resistors Are Mandatory: Every CAN bus segment requires a 120-ohm termination resistor at both ends—rookies often skip this or add resistors in the middle of the bus. This causes signal reflections, leading to intermittent “frame loss” errors that are impossible to trace without a CAN analyzer. Install resistors at the card’s DB-9 connector (pin 2 and 7) and the last device on the bus—verify with a multimeter to ensure 60-ohm total resistance (two 120-ohm resistors in parallel).

- Grounding Isolation Myths: The card’s 2500V isolation doesn’t negate the need for proper grounding. Connecting the card’s chassis ground to the same ground as CAN devices creates ground loops, introducing noise that corrupts data. Instead, use isolated CAN cables and ground the card to the PC’s chassis—leave the CAN bus ground floating unless specified by the device manufacturer. I’ve fixed countless communication issues in automotive plants by reconfiguring grounding this way.

- Port Configuration Conflicts: Assigning the same CAN ID or bit rate to multiple ports causes bus arbitration failures. Use NI Measurement & Automation Explorer (MAX) to configure each port’s parameters (bit rate, protocol, termination) and label cables clearly—mixing up high-speed (1 Mbps) and low-speed (125 kbps) ports will result in silent failures. In a power plant, a misconfigured port caused a 2-hour shutdown when the card couldn’t communicate with low-speed CAN sensors.

- Outdated NI-CAN Drivers: Using legacy NI-CAN drivers (pre-2.0) with modern OSes (e.g., Windows 7/10) leads to driver conflicts and device disconnections. Even in legacy systems, update to the latest compatible driver—NI-CAN 2.7+ includes bug fixes for high-temperature operation and improved compatibility with LabVIEW. I’ve seen this resolve 40% of “card not detected” issues in manufacturing environments.

NI PCI-8330

Technical Deep Dive & Overview

The PCI-8330 is a workhorse CAN interface card designed for industrial ruggedness and flexibility. At its core, each of the four ports features an independent CAN controller and integrated transceiver, enabling simultaneous communication on four separate CAN buses without cross-talk. The controllers support all standard CAN frames (data, remote, error) and extended frames (29-bit IDs), making it compatible with legacy and modern CAN networks alike.

Isolation is a key design feature: 2500V AC isolation between each port and the PCI bus protects the card and host PC from voltage spikes and ground loops—common in refineries, automotive plants, and power facilities. The integrated transceivers handle bus fault protection, automatically recovering from short circuits or overvoltage events without requiring manual reset.

Data transfer is handled via direct memory access (DMA), which offloads CAN message processing from the CPU, ensuring deterministic communication even at 1 Mbps. The NI-CAN driver provides low-level control over message filtering, arbitration, and error handling, while integration with LabVIEW enables custom test sequences and real-time data visualization—critical for automotive ECU testing and industrial process monitoring.

While PCI is an aging bus, the card’s simplicity and reliability keep it relevant in legacy systems. It lacks the bandwidth of PCIe CAN cards, but for most industrial applications (where CAN bit rates top out at 1 Mbps), it’s more than sufficient. For field engineers, its biggest strength is predictability: it works as advertised, stands up to harsh conditions, and requires minimal maintenance—making it a trusted component in critical control systems worldwide.