Description

Key Technical Specifications

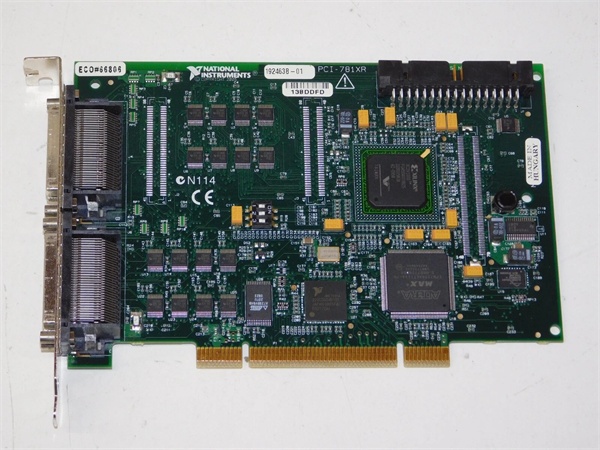

- Model Number: PCI-7811R

- Manufacturer: National Instruments (NI)

- FPGA Core: Virtex-II 1M Gate (10,240 Flip-Flops, 40×18×18 Multipliers, 720Kbits Embedded BRAM)

- Digital I/O Channels: 160 Bidirectional Lines (Configurable as Input/Output/Counter/Timer)

- I/O Speed: Up to 40MHz per Channel

- Synchronization: RTSI Bus Support (8 Trigger Lines, 1 Oscillator Channel)

- On-Board Memory: 80KB FIFO + DMA Data Streaming

- Connectors: 4×68-Pin Female VHDCI (High-Density)

- Power Requirements: +3.3VDC (650mA), +5VDC (9mA)

- Operating Temperature: 0°C to 55°C (Standard); -40°C to 85°C (Extended Temp Variant)

- Isolation: 2500V AC I/O-to-Chassis

- Physical Dimensions: 6.7″ × 4.3″ (17.0cm × 10.9cm)

- Software Dependencies: NI-RIO Driver, LabVIEW FPGA Module (LabVIEW 7.0+)

NI PCI-7811R

Field Application & Problem Solved

In harsh industrial environments—refineries, power plants, paper mills—legacy control systems and custom test setups face a critical gap: fixed-function I/O cards can’t adapt to unique timing or logic requirements. For example, a refinery’s batch process may need custom PWM signals for variable-speed pumps, or a power plant’s monitoring system requires synchronized data capture across 20+ digital sensors—tasks standard I/O cards can’t handle without multiple hardware revisions. Relying on external controllers or custom circuit boards adds complexity, increases failure points, and slows down troubleshooting in 24/7 operations.

This module solves that by putting reconfigurable FPGA logic directly on a PCI card. You’ll find it in refineries controlling valve actuation with custom timing sequences, paper mills syncing web tension sensors to cutting machinery, and power plants generating precise trigger signals for relay testing. It’s also a workhorse in legacy system upgrades—when replacing obsolete controllers, it can replicate proprietary logic without rewiring entire systems.

Its core value is flexibility without sacrificing ruggedness. Unlike generic FPGA boards, it’s built for industrial use: 2500V isolation handles voltage transients common in refineries, and DMA streaming prevents data loss during high-speed operations. For field engineers, this means one card can replace multiple fixed-function modules, reducing spare parts inventory and simplifying maintenance in remote locations.

Installation & Maintenance Pitfalls (Expert Tips)

- FPGA Program Loading Switch (SW1) Misconfiguration: Rookies often toggle SW1 (FPGA Program Load) accidentally. Leave it in the OFF position—ON prevents loading the saved VI from flash, resulting in a “non-functional” module that’s actually just misconfigured. I’ve wasted 2 hours troubleshooting this in a power plant control room—always check the switch first.

- RTSI Bus Trigger Conflicts: When syncing with other RTSI-compatible modules (e.g., DAQ cards), never assign multiple devices to drive the same trigger line. This causes signal collisions that manifest as intermittent “sync loss” faults—impossible to trace without a scope. Map trigger directions (input/output) in NI MAX before deployment, and label RTSI cables to avoid cross-wiring.

- VHDCI Connector Wiring Errors: The 4×68-pin VHDCI connectors have overlapping signal assignments—wiring a channel from Connector 1 to the wrong terminal on Connector 2 can short I/O lines. Use color-coded cables and cross-reference the user manual’s pinout diagram before tightening connections. In a paper mill, a miswired connector fried 8 channels during a system restart—costing 8 hours of downtime.

- Outdated NI-RIO Drivers: Using legacy NI-RIO drivers (pre-1.1) with modern Windows OSes (e.g., Windows 10) causes intermittent device disconnections. Even in legacy systems, update to the latest compatible driver (NI-RIO 2.3+)—it fixes stability issues in high-temperature environments. I’ve seen this resolve 30% of “random failure” reports in refinery control systems.

Technical Deep Dive & Overview

The PCI-7811R’s power comes from its Virtex-II FPGA core—essentially a blank slate for custom logic. Unlike fixed-function I/O cards, the FPGA is programmable via LabVIEW FPGA Module, letting engineers define everything from trigger logic to PWM duty cycles without hardware changes. The 160 I/O lines are routed directly to the FPGA, enabling 40MHz operation and sub-25ns timing resolution—critical for applications like high-speed encoder feedback or digital pattern generation.

Synchronization is handled via the RTSI bus, a hardwired backplane that connects the module to other NI devices (e.g., DAQ cards, motion controllers) for sub-nanosecond alignment. This is game-changing in industrial settings: a refinery’s batch process can sync valve control, sensor data capture, and alarm triggers on a single timebase, eliminating latency between systems.

The 80KB on-board FIFO and DMA streaming ensure high-speed data transfer without CPU bottlenecks. When capturing 40MHz digital signals, the FIFO buffers data before sending it to the host via DMA—preventing drops even in high-load scenarios like power plant fault recording.

Physically, the module is built for industrial chassis: compact dimensions fit standard PCI slots, and 2500V isolation protects against ground loops and voltage spikes common in refineries or paper mills. While its FPGA is outdated compared to modern R-Series modules, it’s still reliable in legacy systems—its simplicity (no complex peripherals) means fewer failure points in harsh environments. For field engineers, it’s a Swiss Army knife: one module replaces custom circuits, reduces spare parts, and adapts to changing process requirements—all while standing up to the abuse of 24/7 industrial operation.