Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PCI – 7811R |

| Manufacturer | National Instruments |

| Product Category | Digital Reconfigurable I/O Device |

| Form Factor | PCI (compatible with standard PCI slots) |

| FPGA | Virtex – II 1M gate FPGA |

| Digital I/O Lines | 160 lines, configurable as inputs, outputs, counters, or custom logic |

| On – board Memory | 80 KB |

| Data Streaming | Supports DMA data streaming |

| Power Requirements | +3.3 VDC, +5 VDC (650 mA at +5 VDC, 9 mA at +3.3 VDC) |

| Connector | Coordinated connector intersection box with screw terminal or link options |

| Certification | NI CompactRIO extreme industrial certifications and ratings |

| Operating Temperature | Refer to NI’s official documentation for specific temperature range suitable for industrial use |

| Storage Temperature | As per NI’s guidelines for proper storage conditions |

| Relative Humidity | Operating humidity range specified in NI’s product documentation for reliable operation |

| Compliance Standards | Meets relevant industry standards for electrical safety, electromagnetic compatibility, and industrial – grade reliability |

| Software Compatibility | LabVIEW, LabVIEW FPGA module for custom FPGA programming; can be controlled via LabVIEW on Windows or LabVIEW Real – Time (RT) targets even without the FPGA module for existing FPGA VIs |

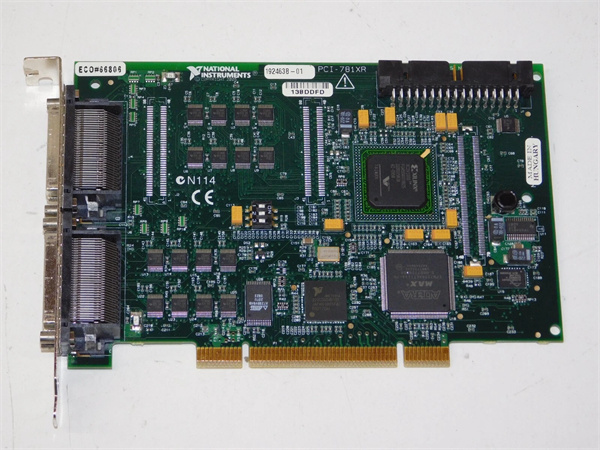

NI PCI-7811R

Product introduction

The National Instruments PCI – 7811R is a high – performance digital reconfigurable I/O device that belongs to NI’s esteemed R series. This device is engineered to meet the diverse and demanding requirements of applications that necessitate flexible digital I/O operations and on – board processing capabilities.

At its core, the PCI – 7811R features a Virtex – II 1M gate Field – Programmable Gate Array (FPGA). This FPGA lies at the heart of the device’s versatility, allowing users to redefine the functionality and timing of the digital I/O lines according to their specific application needs. Whether it’s implementing custom logic for a unique control algorithm or precisely synchronizing multiple digital signals, the FPGA empowers users with a high degree of customization.

The device comes with 160 digital I/O lines that can be configured in multiple ways. These lines can function as traditional digital inputs or outputs, counters for counting events or measuring frequencies, or be used to implement custom logic circuits. This flexibility makes the PCI – 7811R suitable for a wide range of industries and applications, from industrial automation to scientific research.

The coordinated connector intersection box, which is part of each module, offers screw terminal or link options. This provides adaptable and cost – effective signal wiring solutions, ensuring easy integration with various external devices and systems. Additionally, the PCI – 7811R carries the NI CompactRIO extreme industrial certifications and ratings. This means it is built to withstand harsh industrial environments, ensuring reliable operation in settings where temperature, humidity, and electrical noise can pose challenges.

Core advantages and technical highlights

Programmable FPGA for Customization: The programmable FPGA chip on the PCI – 7811R is a game – changer. It enables users to customize the I/O logic and signal processing functions. For example, in a robotics application, users can program the FPGA to implement a custom motion control algorithm. By directly programming the FPGA, the PCI – 7811R can handle the complex and precise timing requirements for controlling the movement of robotic joints, providing a more efficient and tailored solution compared to off – the – shelf controllers.

High – Speed Data Acquisition and Processing: The PCI – 7811R excels in high – speed data acquisition and processing. It can rapidly capture and analyze various digital signals in real – time. In a high – speed manufacturing process, such as a semiconductor wafer inspection line, the PCI – 7811R can quickly acquire digital signals from multiple sensors placed along the production line. It can then process this data in real – time to detect any defects or anomalies in the semiconductor wafers, ensuring high – quality production and minimizing downtime.

Multi – Channel I/O Support: With 160 digital I/O lines, the PCI – 7811R supports multiple I/O channels. This allows it to handle multiple signal sources simultaneously. In an industrial control system that monitors and controls a large number of sensors and actuators, the PCI – 7811R can interface with all these devices through its numerous I/O channels. For instance, in a large – scale power plant, the PCI – 7811R can be used to monitor the status of hundreds of relays, switches, and sensors, and control the operation of various motors and valves, all through its multi – channel I/O capabilities.

DMA Data Streaming: The support for DMA (Direct Memory Access) data streaming ensures efficient data transfer between the PCI – 7811R and the host computer’s memory. This is crucial in applications where large amounts of data need to be transferred quickly, such as in high – speed data logging applications. In a data – intensive scientific experiment, where large volumes of digital data are being generated continuously, the DMA data streaming feature of the PCI – 7811R allows for seamless and fast transfer of this data to the host computer for further analysis, without overloading the system’s resources.

Industrial – Grade Reliability: Thanks to its NI CompactRIO extreme industrial certifications and ratings, the PCI – 7811R is designed to operate reliably in harsh industrial environments. It can withstand temperature variations, humidity, and electrical interference. In a steel manufacturing plant, where there are high temperatures, dust, and strong electromagnetic fields, the PCI – 7811R can continue to function accurately, providing stable digital I/O operations for controlling the various machinery and processes involved in steel production.

Typical application scenarios

Industrial Automation: In industrial automation, the PCI – 7811R plays a vital role. It can be used to control and monitor complex manufacturing processes. For example, in an automotive assembly line, the PCI – 7811R can be configured to control the movement of robotic arms that perform tasks such as welding, painting, and assembling parts. Its digital inputs can receive signals from sensors that detect the presence and position of parts on the assembly line, while its digital outputs can activate the motors and actuators of the robotic arms. The programmable FPGA allows for the implementation of custom control algorithms to ensure smooth and efficient operation of the assembly line.

Test and Measurement in Electronics: In the electronics industry, the PCI – 7811R is used for testing and validating electronic components and devices. It can generate and measure digital signals to test the functionality of integrated circuits (ICs), printed circuit boards (PCBs), and other electronic assemblies. For instance, in an IC testing facility, the PCI – 7811R can be programmed to apply a series of digital test patterns to an IC and measure its output responses. The high – speed data acquisition and processing capabilities of the PCI – 7811R enable quick and accurate testing, helping to identify any faulty components and ensure the quality of the final products.

Scientific Research Experiments: In scientific research, the PCI – 7811R is a valuable tool. It can be used in experiments that require precise control and measurement of digital signals. In a physics experiment studying the behavior of particles in a particle accelerator, the PCI – 7811R can be used to control the timing of various detectors and magnets. Its programmable FPGA can be configured to implement complex trigger and data acquisition logic, ensuring that the experiment can accurately capture and analyze the data related to particle interactions.

NI PCI-7811R

Related model recommendations

NI PCI – 7813R: This is another compactRIO controller with real – time system integration. It offers a more advanced 3M gate Virtex – II FPGA compared to the 1M gate FPGA in the PCI – 7811R. In applications that require even more complex FPGA – based processing, such as in high – end signal processing for radar systems or advanced scientific simulations, the PCI – 7813R can provide the additional processing power. It also has similar industrial – grade certifications, making it suitable for harsh environment applications.

NI USB – 7845R: A USB – based alternative to the PCI – 7811R, the USB – 7845R offers the flexibility of reconfigurable I/O with the convenience of USB connectivity. This makes it ideal for applications where portability is a key factor, such as in field – based testing or in scenarios where a PCI slot may not be available. For example, in a mobile testing laboratory that needs to quickly set up and test various electronic devices in different locations, the USB – 7845R can be easily connected to a laptop via USB and used to perform digital I/O operations.

NI LabVIEW Professional Development System: This software suite is essential for programming and controlling the PCI – 7811R. LabVIEW’s graphical programming environment, especially when combined with the LabVIEW FPGA module, makes it easy to develop custom applications for the PCI – 7811R. Engineers can use LabVIEW to create intuitive user interfaces for controlling the device, as well as to program the FPGA to implement custom logic. It also allows for seamless integration with other NI hardware and software products, enhancing the overall functionality and usability of the PCI – 7811R in a variety of applications.

Installation, commissioning and maintenance instructions

Installation Preparation: Before installing the PCI – 7811R, ensure that the host computer has an available standard PCI slot. Power off the computer and use a screwdriver to open the computer case. Ground yourself using an anti – static wristband to prevent electrostatic discharge (ESD) damage to the card. Install the necessary NI software, which typically includes the NI – RIO device drivers. These drivers can usually be obtained from the NI website or from the provided installation media. Align the PCI – 7811R with the PCI slot and firmly press it into place until it is fully seated. Secure the card to the computer case with the provided screw. Close the computer case and power on the computer.

Commissioning: After installation, open the NI – Measurement & Automation Explorer (MAX). This utility allows you to configure and test the PCI – 7811R. In MAX, you can set up the digital I/O lines according to your application requirements, configure the FPGA settings if you are using custom FPGA programming, and test the device’s functionality. For example, you can connect a simple digital device, such as an LED or a digital logic probe, to one of the I/O lines and use MAX to send and receive digital signals to verify the proper operation of the card. If there are any issues, double – check the connections, software settings, and ensure that the drivers are up to date.

Maintenance Suggestions: Regularly inspect the PCI – 7811R for any signs of physical damage, such as bent pins on the connectors or visible signs of wear. Clean the card and its connectors periodically using compressed air to remove dust and debris, which can affect the electrical connections. If you are using custom FPGA programming, keep a backup of your FPGA code in case you need to re – upload it. Periodically check for software updates from NI, as these may include bug fixes, performance improvements, and new features. If the card experiences issues such as incorrect digital signal readings or communication problems, first check the software settings, update the drivers, and then verify the physical connections. In case of persistent problems, contact NI’s technical support for further assistance.

Service and guarantee commitment

National Instruments provides a standard warranty for the PCI – 7811R, covering defects in materials and workmanship. The warranty period gives users confidence in the product’s quality, knowing that if the device fails due to manufacturing issues, it will be repaired or replaced. NI also offers a global technical support team that is available to assist users with any questions or problems related to the PCI – 7811R. Whether it’s software configuration, hardware compatibility, or troubleshooting, the support team can be reached via email, phone, or online forums.

In addition, NI provides a wealth of online resources for the PCI – 7811R, including user manuals, application notes, and software development kits. These resources help users get the most out of the device, from initial installation to developing complex applications. For customers with critical applications, NI may offer extended support contracts, which can include priority technical assistance, software updates, and additional calibration services, ensuring the long – term reliability and performance of the PCI – 7811R.