Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PCIe-6733 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Speed High-Precision Analog Output Card (PXIe Interface) |

| Electrical performance | 16 single-ended / 8 differential analog output channels; Resolution: 16-bit (65,536 discrete levels); Output ranges: ±10 V, ±5 V, 0–10 V, 0–5 V (software-selectable per channel); Max output current: ±10 mA per channel; Slew rate: 3 V/µs |

| Physical size | Dimensions (L×W×H): 160 mm × 100 mm × 20 mm (standard 3U PXIe form factor); Weight: Approximately 230 g |

| Interface type | PXIe 1.0 compliant (x1 lane, 2.5 Gbps bandwidth); 68-pin VHDCI connector (analog output signals); PXIe Trigger Bus (8 lines) for synchronization; PXIe Backplane Clock (100 MHz) |

| Communication protocol | PXIe bus for data transfer; Compatible with NI-DAQmx driver; Supports DMA (Direct Memory Access) with scatter-gather; Supports SCPI and LabVIEW FPGA programming |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | 3U PXIe chassis mounting (compatible with PXIe 1.0+ chassis); ESD protection (±15 kV air discharge) required; Powered by PXIe backplane (no external power supply) |

| Performance indicators | Output accuracy: ±0.01% full scale (FS) at 25 °C; Linearity error: ±0.005% FS; Per-channel update rate: 2 MS/s; Aggregate update rate: 32 MS/s; Onboard FIFO buffer: 64 kB |

| Power requirements | Typical power consumption: 9 W; Peak power consumption: 14 W (during maximum update rate operation) |

| Compatibility | Supported OS: Windows 10/11 (64-bit); Compatible software: NI LabVIEW, LabWindows/CVI, C/C++, .NET; Integrates with NI TestStand and PXIe Chassis Configuration Utility |

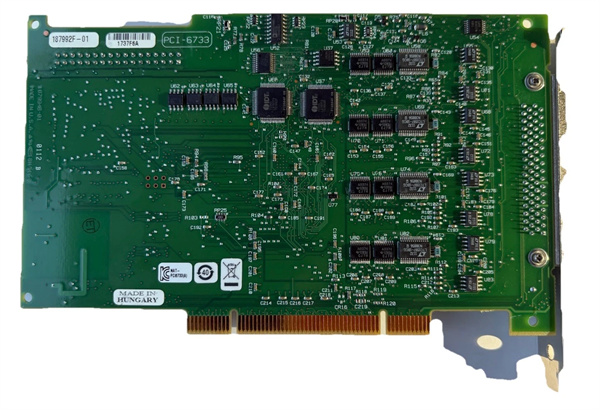

NI PCI-6733

Product introduction

The NI PCIe-6733 is a high-speed high-precision analog output card developed by National Instruments (NI), belonging to NI’s PXIe Analog Output product series—engineered for modular, high-throughput automation systems requiring 16-channel analog signal generation. As a PXIe upgrade to the PCI-based NI PCI-6713, the NI PCIe-6733 retains the same 16-bit resolution and ±0.01% FS accuracy but delivers 2× faster per-channel update rates (2 MS/s vs. 1 MS/s) and PXIe’s native high-bandwidth (2.5 Gbps) for seamless integration into modular test racks (e.g., ATE systems).

In automation systems, the NI PCIe-6733 acts as a “high-speed precision signal core” for coordinated multi-module operations. For example, in a semiconductor wafer test facility, it uses 16 channels to output analog voltages (0–10 V) for calibrating 16 wafer prober sensors simultaneously—each channel delivering 152.59 µV step adjustments at 2 MS/s, cutting calibration time by 40% compared to the NI PCI-6713. Its PXIe Trigger Bus also synchronizes with NI PXIe-6259 DAQ cards within 1 ns, ensuring signal generation and data acquisition align perfectly for high-speed wafer defect detection.

Core advantages and technical highlights

PXIe High-Bandwidth for Faster Data Transfer: The NI PCIe-6733 leverages PXIe x1 lane (2.5 Gbps) bandwidth—5× faster than the NI PCI-6713’s PCI bus (33 MHz, 132 MB/s). This enables real-time playback of large complex waveforms (e.g., 64 kB FIFO preloads 32,000 data points per channel) without latency. For instance, in an automotive radar test rig, the NI PCIe-6733 generates 16 channels of analog radar simulation signals at 2 MS/s—PXIe’s high bandwidth ensures waveform data is transferred from the host PC to the card in 20 µs, avoiding signal gaps that would invalidate test results.

Enhanced Synchronization for Modular Systems: Unlike the NI PCI-6713’s RTSI bus (limited to PCI devices), the NI PCIe-6733 supports PXIe Trigger Bus and Backplane Clock—enabling sub-1 ns synchronization with other PXIe modules (e.g., digitizers, signal generators). In an aerospace flight control test, the NI PCIe-6733 synchronizes 16 channel outputs (simulating actuator commands) with a NI PXIe-5112 digitizer (capturing sensor feedback) across a 10-slot PXIe chassis—ensuring all modules operate in lockstep, critical for validating flight control algorithms.

Dual-Mode Operation (Standard/FPGA): The NI PCIe-6733 integrates a Xilinx Artix-7 FPGA, supporting LabVIEW FPGA programming for custom signal generation (e.g., proprietary protocols or real-time waveform modification). This is a key upgrade from the NI PCI-6713 (no FPGA). For example, in a medical imaging system test, engineers program the FPGA to generate 16 channels of analog signals with dynamic amplitude adjustments (responsive to real-time feedback from a NI PXIe-6259 DAQ card)—mimicking patient tissue impedance variations that standard waveform generation can’t replicate.

Typical application scenarios

In aerospace manufacturing, the NI PCIe-6733 is used for multi-channel actuation test systems. For a commercial aircraft’s flight control unit (FCU) test, it outputs 16 channels of analog signals (±10 V) at 2 MS/s to simulate 16 actuator commands (e.g., aileron, elevator positions). The NI PCIe-6733’s PXIe synchronization aligns these signals with a NI PXIe-6259 DAQ card (measuring FCU output currents) within 1 ns—ensuring engineers accurately verify FCU response times (< 100 µs) to meet FAA standards. Its 64 kB FIFO buffer also preloads 10 seconds of test waveforms, enabling unattended testing of 50+ FCUs per day.

In automotive ADAS (Advanced Driver-Assistance Systems) testing, the NI PCIe-6733 simulates multi-sensor inputs. It generates 16 channels of analog signals (0–5 V) at 2 MS/s to mimic data from cameras, radar, and LiDAR sensors—feeding into an ADAS ECU (Electronic Control Unit) to test collision avoidance algorithms. The NI PCIe-6733’s FPGA programming capability lets engineers dynamically adjust signal amplitudes (e.g., simulating rain-induced radar signal attenuation) in real time, while PXIe high bandwidth ensures no signal latency—critical for validating ECU decision-making at highway speeds.

NI PCI-6733

Related model recommendations

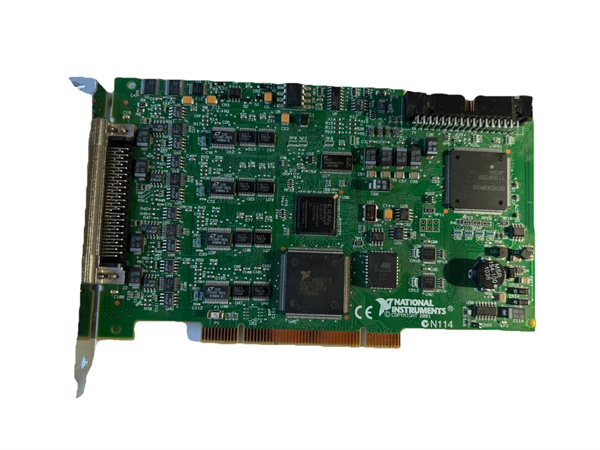

NI PCI-6713: The PCI-based predecessor of the NI PCIe-6733, offering 16 channels, 16-bit resolution, but 1 MS/s per-channel update rate. It is a cost-effective alternative for non-modular systems (e.g., standalone industrial control) and can be upgraded to NI PCIe-6733 for modular high-speed needs.

NI PXIe-6738: A higher-channel variant of NI PCIe-6733, with 32 analog output channels (double the NI PCIe-6733) and identical 2 MS/s per-channel rate. It is ideal for large-scale systems (e.g., 32-sensor calibration labs) requiring more channels.

NI PXIe-6259: A multifunction DAQ card that pairs with NI PCIe-6733. The NI PCIe-6733 generates test signals, while the NI PXIe-6259 acquires DUT responses—synchronized via PXIe Trigger Bus for precision test systems.

NI PXIe-1075: A 5-slot PXIe chassis compatible with NI PCIe-6733. It provides PXIe backplane power and synchronization, enabling modular integration of the NI PCIe-6733 with other PXIe modules.

NI LabVIEW FPGA 2024: Essential software for NI PCIe-6733, enabling FPGA programming to implement custom signal generation logic (e.g., dynamic waveform adjustment). It unlocks the card’s advanced capabilities beyond standard analog output.

NI TB-4353: A precision terminal block for NI PCIe-6733, offering 68-pin VHDCI connectivity and built-in signal conditioning for bridge sensors. It ensures accurate signal transmission between the NI PCIe-6733 and DUTs.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCIe-6733, power off the PXIe chassis (e.g., NI PXIe-1075) and confirm an empty 3U PXIe slot. Wear an ESD wristband (rated ±15 kV) and work on a grounded bench to protect the card’s FPGA and analog circuits. Align the NI PCIe-6733 with the chassis guide rails, insert firmly until the backplane connector is fully seated, then secure with the chassis front panel screw. Connect DUTs to the 68-pin VHDCI connector using shielded twisted-pair cables (50 Ω impedance-matched). Install the latest NI-DAQmx driver and PXIe Chassis Configuration Utility, then use NI Measurement & Automation Explorer (MAX) to detect NI PCIe-6733 and run a precision self-test (verifying output accuracy and PXIe synchronization).

Maintenance suggestions: Calibrate NI PCIe-6733 every 6 months using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±0.01% FS accuracy—PXIe chassis temperature fluctuations > 2 °C can degrade precision. Inspect the VHDCI connector monthly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust. If NI PCIe-6733 experiences FPGA communication errors, reinstall the LabVIEW FPGA driver or update the card’s firmware via MAX. Avoid exposing NI PCIe-6733 to vibration > 5 g (e.g., during chassis transportation) to prevent damage to its precision DACs and FPGA. Replace the card’s backplane connector pins (available via NI’s spare parts program) every 5 years to ensure reliable PXIe communication.

Service and guarantee commitment

National Instruments (NI) provides a 3-year standard warranty for NI PCIe-6733, covering defects in materials and workmanship—specifically including PXIe backplane compatibility and FPGA functionality. For extended protection, the ServicePlus Premium plan extends coverage to 7 years, including annual factory calibration (traceable to NIST) for all 16 channels, priority technical support (2-hour response time for PXIe synchronization issues), and expedited repairs (turnaround time < 2 business days).

NI’s global technical team (specialized in PXIe modular systems) offers 24/7 support for NI PCIe-6733, assisting with FPGA programming, PXIe chassis integration, and high-speed waveform troubleshooting. Customers gain free access to exclusive resources: application notes on PXIe multi-module synchronization, LabVIEW FPGA example code for NI PCIe-6733, and a user community for sharing modular test best practices. For out-of-warranty repairs, NI’s Precision Restore Service restores NI PCIe-6733 to factory specs—replacing aged FPGA components and verifying 2 MS/s update rate and ±0.01% FS accuracy—reflecting NI’s confidence in the card’s durability and commitment to supporting high-speed modular automation workflows.