Description

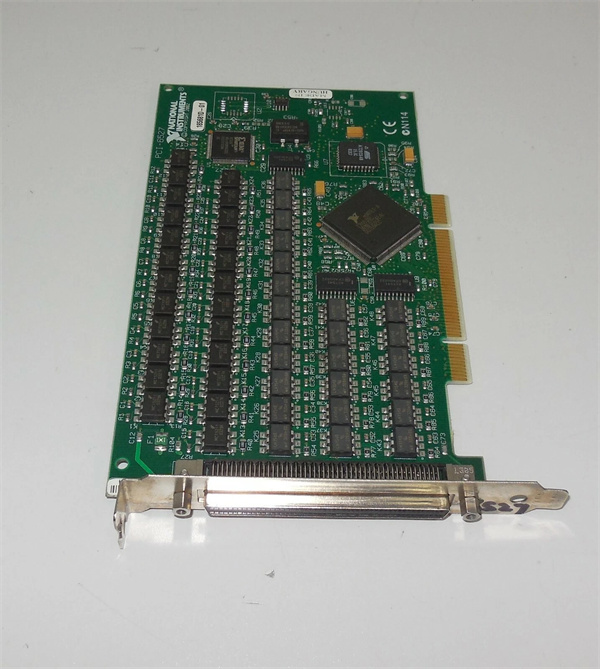

NI PCI – 6527 Product Description

1. General Information

Product Model: NI PCI – 6527

Manufacturer: National Instruments (NI)

Product Category: High – Speed Digital I/O Card (PCI Interface)

2. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Digital I/O Performance | |

| I/O Lines | 32 lines (configurable as input or output); Logic levels: 5 V TTL/CMOS; 24 mA sink/source current per line |

| Timing | High – speed operation up to 80 MHz; Support for hardware – timed digital I/O; Pulse width generation as low as 12.5 ns |

| Data Transfer | PCI bus data transfer; Supports scatter – gather DMA for high – throughput data transfer |

| Physical Size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 200 g |

| Interface Type | PCI 2.3 compliant (32 – bit, 33 MHz); Dual 68 – pin SCSI – II connectors for digital signals; RTSI bus connector (8 – line) for multi – device synchronization |

| Communication Protocol | PCI bus for data transfer; Compatible with NI – DAQmx (primary) and legacy Traditional NI – DAQ; Supports register – level programming and SCPI |

| Environmental Requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: – 20 °C to 70 °C; Relative humidity: 10% to 90% (non – condensing); Operating altitude: Up to 2000 m; Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half – sine) |

| Installation Method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); Easy – to – install design for seamless integration into existing systems |

| Performance Indicators | Digital I/O setup time: 10 ns; Hold time: 5 ns; Maximum data transfer rate: 132 MB/s (PCI bus limit); Channel – to – channel skew: < 5 ns |

| Power Requirements | Powered by PCI bus (typical: 8 W); Peak power consumption: 12 W |

| Compatibility | Works with Windows 7/10/11 (32 – bit/64 – bit); Compatible with NI LabVIEW (v2010+), LabWindows/CVI, C/C++, .NET, Python; Full NI – DAQmx support for high – speed digital I/O operations |

NI PCI-6527

3. Product Introduction

The NI PCI – 6527 is a high – speed digital I/O card from National Instruments, designed to meet the demands of applications that require rapid and reliable digital signal handling. It is an ideal solution for engineers and scientists working on projects such as high – speed data acquisition, industrial automation, and test and measurement systems.

Unlike some general – purpose digital I/O cards, the PCI – 6527 focuses on delivering high – speed performance. With its 32 configurable I/O lines, it can interface with a wide range of digital devices, from simple sensors and actuators to complex digital systems. The card’s ability to operate at speeds up to 80 MHz makes it suitable for applications where timing is critical, such as in high – speed serial communication protocols or high – speed data logging.

For example, in a high – speed data acquisition system for a research laboratory, the PCI – 6527 can be used to capture digital signals from multiple sources simultaneously. It can accurately record the state changes of digital sensors at high frequencies, ensuring that no data is lost during the acquisition process. In an industrial automation setting, it can control high – speed actuators with precise timing, enabling smooth and efficient operation of manufacturing processes.

The PCI – 6527 also offers excellent compatibility with NI’s software ecosystem. Through NI – DAQmx, it can be easily integrated with popular programming environments like LabVIEW, LabWindows/CVI, and Python. This allows users to develop custom applications quickly and efficiently, taking full advantage of the card’s capabilities.

4. Core Advantages and Technical Highlights

4.1 High – Speed Operation

The PCI – 6527’s ability to operate at up to 80 MHz sets it apart from many other digital I/O cards. This high – speed performance enables it to handle rapid digital signal transitions, making it suitable for applications such as high – speed serial data transfer, where signals change state at very high frequencies. For instance, in a high – speed data communication system, the card can accurately transmit and receive digital data at speeds that meet the requirements of modern high – bandwidth applications. The short pulse width generation of 12.5 ns also allows for precise control of digital signals, which is crucial in applications like high – speed pulse – based control systems.

4.2 Configurable I/O Lines

With 32 configurable I/O lines, the PCI – 6527 offers great flexibility. Users can easily configure these lines as either input or output, depending on their application needs. This flexibility makes it suitable for a wide range of applications. In a test and measurement setup, some lines can be configured as inputs to receive digital signals from devices under test, while others can be used as outputs to control the test equipment. In an industrial control system, the configurable I/O lines can interface with various sensors and actuators, allowing for comprehensive control and monitoring of the production process.

4.3 Scatter – Gather DMA

The card’s support for scatter – gather DMA significantly improves data transfer efficiency. When transferring large amounts of digital data, scatter – gather DMA can split the data into smaller blocks and transfer them to non – contiguous memory locations, reducing the CPU load. This is especially beneficial in applications where high – volume data transfer is required, such as in high – speed data logging systems. For example, when logging digital data from multiple sensors at high speeds, the scatter – gather DMA on the PCI – 6527 can ensure that the data is transferred to the computer’s memory quickly and efficiently, without overloading the CPU.

4.4 RTSI Bus for Synchronization

The inclusion of an 8 – line RTSI (Real – Time System Integration) bus connector allows for easy synchronization with other NI devices. In multi – device setups, such as a complex test and measurement system with multiple DAQ cards and other instruments, the RTSI bus can be used to ensure that all devices operate in perfect synchronization. This is crucial for applications where accurate timing between different devices is required, such as in a multi – channel data acquisition system where all channels need to be sampled simultaneously.

5. Typical Application Scenarios

5.1 High – Speed Data Acquisition in Research Labs

In a research laboratory studying high – speed physical phenomena, the NI PCI – 6527 can be used to capture digital signals from multiple sensors. For example, in a study of high – speed chemical reactions, digital sensors may be used to detect the state changes of various reactants at high frequencies. The PCI – 6527 can accurately record these digital signals at speeds up to 80 MHz, providing researchers with high – resolution data for analysis. The 32 configurable I/O lines allow for connection to multiple sensors simultaneously, and the scatter – gather DMA ensures efficient data transfer to the computer for further processing.

5.2 Industrial Automation

In an industrial manufacturing plant, the PCI – 6527 can play a vital role in automating production processes. It can be used to control high – speed actuators, such as those in a high – speed packaging machine. The card’s ability to generate short pulse widths (as low as 12.5 ns) enables precise control of the actuators, ensuring accurate and efficient packaging. The configurable I/O lines can also interface with various sensors on the production line, such as proximity sensors and limit switches, to monitor the status of the manufacturing process. In case of any 异常,the card can quickly send out digital signals to trigger alarms or corrective actions.

5.3 Test and Measurement Systems

For test and measurement applications, the PCI – 6527 is an excellent choice. In a semiconductor testing facility, it can be used to interface with semiconductor devices under test. The 32 I/O lines can be configured to send and receive digital signals to and from the semiconductor device, while the high – speed operation of the card allows for rapid testing of high – speed digital circuits. The RTSI bus can be used to synchronize the PCI – 6527 with other test equipment, such as signal generators and oscilloscopes, ensuring accurate and consistent test results.

NI PCI-6527

6. Related Model Recommendations

6.1 NI PCI – 6534

The PCI – 6534 is a high – performance digital I/O card that offers even higher speeds (up to 100 MHz) compared to the PCI – 6527. It also has 32 I/O lines and is suitable for applications where extreme high – speed digital signal handling is required. However, it may be more expensive than the PCI – 6527, so it is a better choice for applications that specifically need the extra speed and can justify the higher cost.

6.2 NI USB – 6501

The USB – 6501 is a more portable and cost – effective option. It offers 8 digital I/O lines and is powered by USB, making it easy to use in field applications or in situations where a PCI slot is not available. While it does not have the high – speed capabilities of the PCI – 6527, it can still handle basic digital I/O tasks for applications that do not require high – speed operation.

6.3 NI LabVIEW 2024

LabVIEW 2024 is an essential software for maximizing the capabilities of the PCI – 6527. It provides a graphical programming environment that allows users to easily develop applications for digital I/O control, data acquisition, and synchronization. With LabVIEW, users can create custom interfaces to control the PCI – 6527, display real – time data, and perform complex data analysis.

6.4 NI DAQmx Driver

The NI DAQmx driver is crucial for the proper functioning of the PCI – 6527. It provides a common API for communicating with the card and simplifies the process of configuring and using the digital I/O lines, as well as handling data transfer. Regularly updating the DAQmx driver ensures compatibility with the latest operating systems and software, and may also include performance improvements and bug fixes.

7. Installation, Commissioning and Maintenance Instructions

7.1 Installation Preparation

Before installing the PCI – 6527, power off the PC and ensure that it has an available PCI 2.1/2.2/2.3 slot. Wear an ESD (Electro – Static Discharge) wristband and use a grounded workbench to protect the card from electrostatic damage. Insert the card firmly into the PCI slot, making sure that the PCI edge connector is fully seated. Secure the card with the chassis screw to prevent it from moving.

Connect the digital devices to the dual 68 – pin SCSI – II connectors on the card. Use appropriate cables and connectors to ensure a proper electrical connection. For multi – device synchronization, connect the RTSI bus cable to other NI devices as required.

Download the latest NI – DAQmx driver from NI’s official website. Install the driver on the computer and use NI Measurement & Automation Explorer (MAX) to detect the PCI – 6527. Run basic self – tests in MAX to verify that the card is functioning properly.

7.2 Maintenance Suggestions

To ensure the long – term reliable operation of the PCI – 6527, it is recommended to perform regular checks. Inspect the connectors on the card periodically to make sure they are clean and free of corrosion. Use a lint – free cloth and isopropyl alcohol to clean the contacts if necessary.

Monitor the card’s operating temperature. Although it has an operating temperature range of 0 °C to 55 °C, it is advisable to keep the temperature as stable as possible within this range. High temperature fluctuations can affect the card’s performance over time.

Update the NI – DAQmx driver regularly to benefit from the latest features, bug fixes, and compatibility improvements. Also, back up any custom configurations or calibration data related to the card to a secure location in case of system failures or hardware replacements.

8. Service and Guarantee Commitment

National Instruments provides a standard 1 – year warranty for the PCI – 6527, covering defects in materials and workmanship. For users who require extended protection, NI offers additional service plans. The NI Hardware Service Program can extend the coverage for up to three years, providing benefits such as priority repair services, firmware updates, and factory calibration.

In case the card requires repair or calibration, users can navigate to the NI Service Request Manager (SRM) via ni.com/ask. Select the relevant task (repair or calibration), enter the product details, and provide the necessary information. NI will then contact the user to proceed with the repair or calibration process.

NI also maintains a user forum where customers can share experiences, ask questions, and get support from other users and NI experts. This community – driven support can be valuable for users looking for practical tips and solutions for using the PCI – 6527 in their applications.