Description

Key Technical Specifications

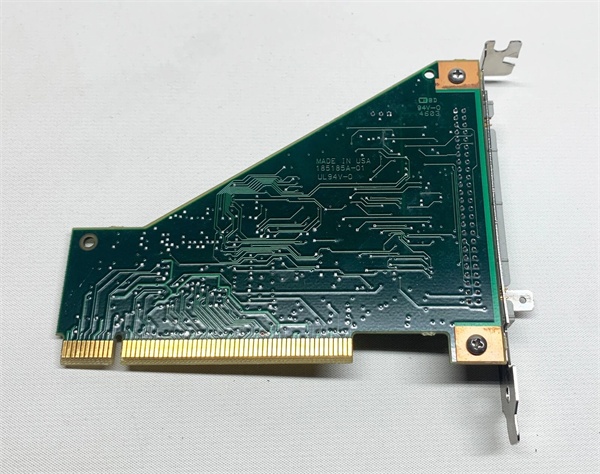

| Technical Indicator | Details |

|---|---|

| Manufacturer | National Instruments (NI) |

| Core Chip | 1 x 82C55A Programmable Peripheral Interface (PPI) chip |

| Digital I/O Configuration | 24 bidirectional digital I/O channels, accessible via a 50-pin male ribbon cable connector |

| Electrical Performance | 5V TTL/CMOS compatible; 2.4mA single-ended digital I/O channel current drive; digital input/output voltage range of 0V – 5V |

| Data Transfer Rate | Up to 50 KB/s maximum rate, typical constant sustainable rate of 1 – 10 bytes per second (with NI-DAQ software) |

| Power Supply Requirement | Operates at +5VDC (±5%), requiring 400mA current; I/O connector output power ranges from +4.65V to +5.25V |

| Physical Size & Weight | Dimensions of 4.8 x 3.7 inches; weight of 1.9 ounces |

| Operating & Storage Environment | Operating temperature: 0°C – 55°C; Storage temperature: -20°C – 70°C; Operating random vibration: 0.31 grms (5 – 500Hz); Non-operating random vibration: 2.5 grms (5 – 500Hz) |

| Special Functions | DC 1500V voltage isolation, reverse connection protection; relay alarm output, fiber link fault and power fault alarm output |

| Software & System Compatibility | Supports Windows, Linux systems; compatible with LabVIEW, MATLAB, NI-DAQmx drivers; supports programming languages such as C/C++ |

NI PCI-6503

Field Application & Problem Solved

In traditional digital I/O applications, many old-fashioned data acquisition cards had obvious drawbacks. For example, they required manual adjustment of jumpers and switches to set base addresses and interrupt levels during use, which was not only cumbersome to operate but also prone to configuration errors. In addition, some industrial on-site devices had problems such as complex wiring and poor signal stability when connecting to computers, and external power supply of some cards also brought inconvenience to on-site deployment. Meanwhile, in teaching and small laboratory scenarios, equipment compatibility and operation difficulty were important factors restricting the efficiency of experiments.

The NI PCI-6503 effectively addresses these pain points. Its completely jumper-free and switch-free design enables automatic allocation of all resources during startup, eliminating the need for manual parameter setting. For instance, in the electronic component production line, it connects to testing instruments to control the start and stop of the testing process and collect whether the product’s output signals are qualified, which simplifies the testing setup and reduces human operation errors. In university electronic technology laboratories, students use it to connect computers and signal generators. With its plug-and-play feature, they can quickly build experimental platforms and complete experiments on digital signal interaction. Moreover, its 1500V voltage isolation and reverse connection protection functions ensure stable operation even in harsh industrial environments with voltage fluctuations, avoiding damage to the card and connected equipment due to abnormal circuits.

Installation & Maintenance Pitfalls (Expert Tips)

- Driver Matching Errors: Using mismatched NI-DAQ software versions may lead to low transfer rates or failure to recognize the card. Some users arbitrarily install the latest NI-DAQmx driver, which may be incompatible with the card’s hardware logic. It is recommended to install the driver version verified by NI for the PCI-6503. You can query the matching driver list on NI’s official website to ensure the card achieves the standard 50 KB/s transfer rate and stable operation of various working modes.

- Incorrect PCI Slot Installation: Inserting the card into an incompatible PCI slot will cause it to fail to work. For example, inserting it into a PCIe slot (with different interface specifications) or a damaged PCI slot will result in the system not detecting the device. Before installation, confirm that the motherboard slot is a standard PCI bus slot. After insertion, press the card firmly to ensure it is fully connected to the slot, and fasten the fixing screw to prevent poor contact caused by vibration.

- Neglecting Power Stability: Unstable power supply of the host computer will affect the card’s signal output accuracy. The PCI-6503 relies on the host’s +5VDC power supply. If the host’s power supply module is aging, it may cause voltage fluctuations beyond ±5%, resulting in distorted digital signals output by the card. It is recommended to use a stable power supply for the host. For industrial on-site applications, you can additionally configure a power filter to reduce the impact of power interference.

- Ignoring Wiring Protection: Lack of protective measures during wiring may damage the card due to overvoltage. Although the card has 1500V voltage isolation, when connecting industrial equipment with large voltage fluctuations, the instantaneous voltage may exceed the bearing limit. It is advisable to use shielded cables for wiring to reduce electromagnetic interference. At the same time, add a surge protector at the connection terminal of external equipment to avoid the card being burned out due to sudden voltage surges.

Field Application & Problem Solved

In traditional digital I/O application scenarios, there were many inconveniences. Early digital I/O cards required manual setting of base addresses and interrupt levels through jumpers and switches, which was not only error-prone but also time-consuming. When used in industrial on-site environments, voltage fluctuations and reverse wiring often damaged the equipment interface. In addition, for teaching and small laboratory scenarios, complex configuration steps also increased the difficulty of use for novices.

The NI PCI-6503 solves these problems well. Its automatic resource allocation function realizes full automatic allocation of resources during startup, eliminating the need for manual parameter setting. For example, in a small electronic component production line, the card is connected to a sorting machine. It can quickly complete the connection with the host computer without complicated configuration, and control the sorting machine to screen unqualified products by collecting the detection signals of sensors. In university electronic experiment courses, students can directly insert the card into the computer’s PCI slot, and use LabVIEW to write simple programs to control the on-off of LED lights, which lowers the threshold for getting started with digital I/O experiments. Its reverse connection protection and 1500V voltage isolation functions also ensure stable operation in industrial environments with harsh power supply conditions, reducing the failure rate caused by wiring and voltage problems.

NI PCI-6503

Technical Deep Dive & Overview

The core advantage of the NI PCI-6503 lies in its user-friendly design and stable basic performance. The 82C55A PPI chip it is equipped with is the key to realizing multiple working modes. This chip allows the card to operate in unidirectional, bidirectional, and handshake modes. In handshake mode, it can complete data interaction and collaborative work with peripheral equipment through interrupt requests, which is very suitable for scenarios such as small – batch production line product testing that require coordinated operation between the host computer and external equipment.

Its plug-and-play and jumper-free design is a major highlight in practical use. Different from traditional digital I/O cards that require opening the chassis for manual configuration, this card can be automatically recognized by the system after being inserted into the PCI slot. The host computer can complete resource allocation during startup, which greatly shortens the time for building test systems. This design is particularly practical in scenarios where test equipment needs to be frequently deployed and adjusted, such as mobile laboratory testing.

However, the product also has obvious limitations. Its maximum transfer rate of 50 KB/s is far lower than that of high-speed digital I/O cards such as NI PCIe-6570. It can only meet simple data collection and control needs, and cannot be applied to high-speed data acquisition scenarios such as high-frequency signal sampling. In addition, as a PCI bus card, it is gradually being replaced by PCIe bus cards with higher bandwidth with the popularity of PCIe interfaces on mainstream motherboards. But for scenarios that do not pursue high performance, such as basic teaching experiments, small-scale process control, etc., the NI PCI-6503 still has strong cost performance and stability, and is still a common choice for maintaining legacy test systems and building low-cost digital I/O solutions.