Description

Detailed parameter table

**

| Parameter name | Parameter value |

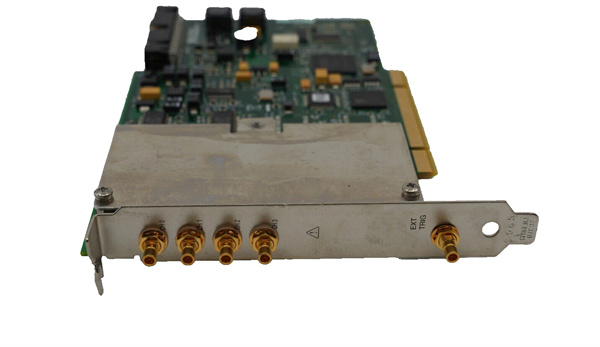

| Product model | NI PCI-4474 |

| Manufacturer | National Instruments (NI) |

| Product category | Sound and Vibration DSA Device (PCI Interface) |

| Electrical performance | Number of channels: 4 simultaneously sampled differential analog input channels; ADC resolution: 24-bit; Sampling rate: Programmable, up to 102.4 ks/s; Dynamic range: >110 dB (at 51.2 ks/s with 16k FFT); AC/DC coupling: Software-selectable; High pass filter cut off frequency: 3.4 Hz; Input impedance: N/A (depends on coupling and sensor type); Measurement functions: Suitable for sound and vibration examination, can measure dynamic signals from powered systems like turbines, blowers, etc. |

| Physical size | Dimensions (L×W): 17.5 cm × 10.7 cm (6.9 in × 4.2 in); Weight: Approximately 184 g (6.5 oz) |

| Interface type | PCI interface (compatible with relevant PCI standards); SMB front connectors for analog input; Digital trigger connector: SMB male |

| Communication protocol | Communicates via PCI bus; Compatible with NI-DAQmx driver software; Supports integration with software like LabVIEW, LabWindows/CVI, or Measurement Studio |

| Environmental requirements | Operating temperature: 0 °C to 50 °C; Storage temperature: -20 °C to 70 °C; Operating random vibration: 5 to 500 Hz (0.3 grms); Non – operating random vibration: 5 to 500 Hz (2.4 grms); Relative humidity: N/A (but should be non – condensing in general); Operating altitude: N/A (but common industrial/lab altitude ranges applicable) |

| Installation method | Installs into a standard PCI slot in a PC; Mounting requires proper electrostatic discharge (ESD) precautions. |

| Performance indicators | Low noise and low distortion, achieved through advanced delta – sigma ADCs; Exceptional linearity due to 1 – bit quantifier oversampling; Can perform arranged examination on dynamic signals; Supports online processing for condition – based monitoring and predictive maintenance applications |

| Power requirements | Power consumption details not fully specified, but draws power from the PCI bus; Current requirements: 2000 mA max (PCI – 4474) |

| Compatibility | Works with operating systems compatible with NI – DAQmx driver (e.g., Windows operating systems commonly used in industrial and lab settings); Compatible with NI LabVIEW, LabWindows/CVI, Measurement Studio, and other software that can interface with NI – DAQmx |

| Special features | Self – calibration on software command; External calibration recommended at least once a year; Insensitive to DNL distortion related to traditional data acquisition devices; Recommended warm – up time of 15 minutes |

NI PCI-4474

Product introduction

The NI PCI-4474 is a high – performance sound and vibration dynamic signal acquisition (DSA) device developed by National Instruments (NI), a globally recognized leader in test, measurement, and automation solutions. Engineered to meet the demanding requirements of applications that demand precise sound and vibration analysis, the PCI – 4474 brings laboratory – grade measurement capabilities directly to a PC’s PCI slot.

Designed for engineers, researchers, and technicians involved in fields such as mechanical engineering, acoustics, and quality control, the NI PCI – 4474 offers four simultaneously sampled differential analog input channels. Equipped with 24 – bit ADCs, it provides the essential precision for accurate sound and vibration measurements. This device is not just a simple data acquisition card; it is a comprehensive solution for applications where the integrity of dynamic signals is crucial. Whether it’s analyzing the vibration patterns of a high – speed turbine or measuring the sound quality of a new audio device, the PCI – 4474 is up to the task.

At its heart, the NI PCI – 4474 combines advanced hardware design with powerful software compatibility. Leveraging NI’s NI – DAQmx driver, it seamlessly integrates with a wide range of software tools. LabVIEW, for example, allows users to create custom, intuitive interfaces for real – time data visualization and analysis. This integration enables the creation of applications for condition – based monitoring and predictive maintenance, where the ability to process and act on data in real – time can prevent equipment failures and reduce maintenance costs.

Core advantages and technical highlights

High – Resolution and Wide Dynamic Range

The NI PCI – 4474 sets itself apart with its 24 – bit ADC resolution, which enables it to capture minute details in sound and vibration signals. This high resolution, combined with a dynamic range of over 110 dB (at 51.2 ks/s with a 16k FFT), ensures that even the most subtle signal variations are accurately measured. For instance, in a structural vibration analysis of a precision instrument, the PCI – 4474 can detect vibrations as small as a fraction of a micron, providing engineers with the data needed to ensure the instrument’s optimal performance. This level of precision is critical in applications where small changes in vibration or sound can indicate potential problems, such as in aerospace component testing.

Advanced Delta – Sigma ADC Technology

The device utilizes advanced delta – sigma ADCs, which are key to its low – noise and low – distortion performance. These ADCs, with their 1 – bit quantifier oversampled at a multiple of the specified sampling rate, produce exceptional linearity. The resulting measurements are highly accurate and free from the non – linear distortion issues often associated with traditional data acquisition devices. In audio test and measurement applications, this means that the PCI – 4474 can accurately reproduce the true characteristics of sound signals, whether it’s measuring the frequency response of a speaker or the harmonic distortion of an amplifier.

Versatile Signal Conditioning and Analysis

With software – selectable AC/DC coupling and a 3.4 Hz high – pass filter, the NI PCI – 4474 can be configured to handle a wide variety of input signals. The ability to perform arranged examination on dynamic signals from powered systems, such as turbines, blowers, pumps, and motors, makes it a versatile tool in industrial settings. The on – board processing capabilities further enhance its utility, allowing for real – time data analysis. For example, in a machine condition monitoring application, the PCI – 4474 can analyze vibration signals in real – time to detect early signs of bearing wear or misalignment, enabling proactive maintenance and reducing unplanned downtime.

Self – Calibration and Reliable Operation

The PCI – 4474 features self – calibration on software command, which helps maintain measurement accuracy over time. Additionally, external calibration is recommended at least once a year for the highest – precision applications. The device’s robust design, with specified operating and non – operating vibration tolerances, ensures reliable performance in challenging environments. In industrial plants or research labs where equipment is subject to mechanical vibrations, the PCI – 4474 can continue to operate accurately, providing consistent and trustworthy data for analysis.

Typical application scenarios

Noise and Vibration Diagnostics in Industrial Machinery

In industrial settings, the NI PCI – 4474 is widely used for diagnosing the health of machinery. For example, in a large – scale manufacturing plant, the device can be installed to monitor the vibration of large motors. By continuously measuring and analyzing the vibration signals, it can detect early signs of imbalance, misalignment, or bearing wear. The 24 – bit resolution allows for the detection of even the smallest changes in vibration patterns, which may indicate potential failures. This early detection can prevent costly breakdowns, reduce maintenance costs, and improve overall plant productivity. The device’s ability to handle multiple channels simultaneously also enables the monitoring of different parts of the machinery at the same time, providing a comprehensive view of its operational health.

Audio Test and Measurement in Product Development

For companies involved in audio product development, such as speaker manufacturers or audio equipment producers, the NI PCI – 4474 is an invaluable tool. It can be used to measure the sound quality of speakers, headphones, or microphones with high precision. By accurately measuring parameters like frequency response, distortion, and sound pressure level, engineers can optimize the design of their products. For instance, when developing a new high – end speaker system, the PCI – 4474 can be used to measure the sound output at different frequencies and volumes. The data obtained can then be used to fine – tune the speaker’s design, ensuring that it delivers the best possible audio experience to the end – user.

Structural Vibration Analysis in Aerospace and Automotive Industries

In the aerospace and automotive industries, understanding the structural vibration of components is crucial for safety and performance. The NI PCI – 4474 can be used to analyze the vibration of aircraft wings during flight simulations or automotive chassis during road tests. In aerospace, even the smallest vibration can affect the aerodynamics and structural integrity of an aircraft. The PCI – 4474’s high – resolution measurements can help engineers identify areas of concern and make design improvements. Similarly, in the automotive industry, measuring the vibration of a car’s chassis can help improve ride comfort and durability. By accurately measuring and analyzing these vibrations, manufacturers can develop more robust and comfortable vehicles.

NI PCI-4474

Related model recommendations

NI PCI – 4472

The NI PCI – 4472 is another member of the NI dynamic signal acquisition family. It offers 8 – channel input, which can be useful in applications where a larger number of measurement points are required, such as in large – scale machinery monitoring or multi – sensor data acquisition. While it has a different channel configuration compared to the PCI – 4474, it shares similar high – performance capabilities in terms of dynamic signal acquisition. It may be a suitable choice for users who need to expand their measurement capabilities beyond the 4 – channel limit of the PCI – 4474.

NI PXI – 4472

The NI PXI – 4472 is a PXI – based version of the dynamic signal acquisition device. It is designed for use in modular test systems and offers the advantage of the PXI platform, such as high – speed data transfer and synchronization capabilities. If you are working in a PXI – based test environment and require sound and vibration measurement capabilities similar to the PCI – 4474, the PXI – 4472 could be a great option. It also has different power requirements and physical dimensions compared to the PCI – 4474, which may be more suitable for certain system integration scenarios.

NI LabVIEW

NI LabVIEW is an essential software for maximizing the capabilities of the NI PCI – 4474. It provides a graphical programming environment that allows users to easily create custom applications for data acquisition, analysis, and visualization. With LabVIEW, you can quickly build interfaces to display real – time sound and vibration data from the PCI – 4474, perform complex signal processing algorithms, and create automated test sequences. For example, you can use LabVIEW to create a dashboard that shows the vibration levels of multiple channels in real – time, with alarms that trigger when certain thresholds are exceeded.

NI – DAQmx

The NI – DAQmx driver software is the backbone of the NI PCI – 4474’s operation. It provides the necessary interface between the hardware and the software applications. Ensuring that you have the latest version of NI – DAQmx installed is crucial for optimal performance and compatibility. The driver software allows for easy configuration of the PCI – 4474’s settings, such as sampling rate, channel configuration, and trigger options. It also enables seamless integration with other NI software tools and third – party applications that support NI – DAQmx.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCI – 4474, power off the PC and ensure that it has an available PCI slot that is compatible with the device. Wear an ESD wristband to protect the card from electrostatic discharge, as static electricity can damage the sensitive components. Gently insert the PCI – 4474 into the PCI slot, making sure it is properly seated, and then secure it with the appropriate chassis screw.

Connect the input signals to the SMB front connectors using suitable cables. For accurate sound and vibration measurements, use high – quality shielded cables to minimize noise interference. When connecting sensors, ensure that the connections are secure and that the sensor output is compatible with the input requirements of the PCI – 4474.

Download and install the latest version of the NI – DAQmx driver software from NI’s official website. After installation, use NI’s Measurement & Automation Explorer (MAX) to detect the PCI – 4474. In MAX, you can configure the device settings, such as sampling rate, channel configuration, and calibration options.

Maintenance suggestions

To maintain the accuracy and performance of the NI PCI – 4474, it is recommended to perform self – calibration on a regular basis, at least once every few months. This can be done through software commands within the NI – DAQmx driver or using compatible applications like LabVIEW.

Inspect the SMB connectors regularly for any signs of damage, corrosion, or loose connections. If any issues are detected, clean the connectors using a suitable contact cleaner and ensure that the connections are tightened properly. Avoid exposing the PC and the PCI – 4474 to extreme temperatures, humidity, or mechanical vibrations outside of the specified operating conditions, as this can affect the device’s performance and lifespan.

If you notice any abnormal behavior or inaccurate measurements, use MAX to run diagnostic tests on the PCI – 4474. Update the NI – DAQmx driver software whenever new versions are available to ensure compatibility with the latest operating systems and to benefit from bug fixes and performance improvements.

Service and guarantee commitment

National Instruments (NI) provides a standard warranty for the NI PCI – 4474, which covers defects in materials and workmanship. The exact duration of the warranty can be found in NI’s official product documentation. For customers who require additional protection, NI offers extended warranty plans, such as the ServicePlus Premium plan. This plan not only extends the warranty period but also includes benefits like priority technical support, annual calibration services, and expedited repairs.

NI’s global technical support team is available to assist users with any questions or issues related to the PCI – 4474. Whether it’s a problem with installation, calibration, or software integration, you can reach out to NI’s support via phone, email, or online chat. Additionally, NI provides a wealth of online resources, including application notes, user manuals, and example code, to help users make the most of the PCI – 4474 in their applications.