Description

Key Technical Specifications

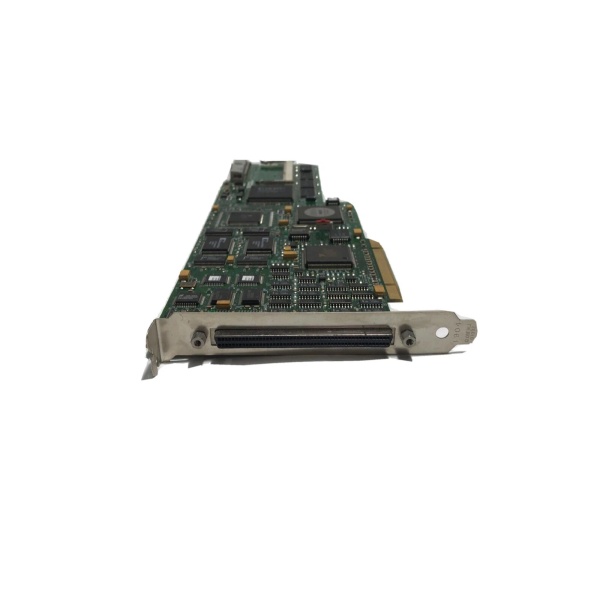

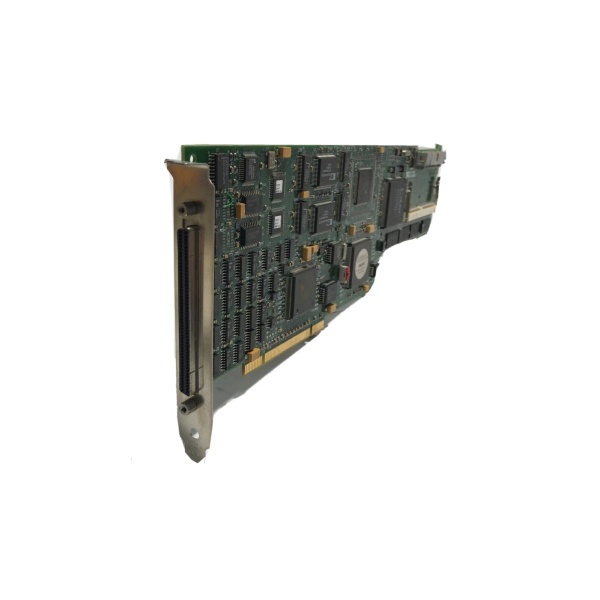

- Model Number: PCI-1424

- Manufacturer: National Instruments (NI)

- Interface Standard: Camera Link Base (1x), Compliant with Camera Link 1.2

- Image Support: 24-Bit RGB Color, 8/10/12-Bit Monochrome (Software-Configurable)

- Pixel Clock: Up to 85 MHz (Max Data Rate: 255 Mbps)

- Bus Interface: 32-Bit PCI (33 MHz), Plug-and-Play Compliant

- Data Transfer: Direct Memory Access (DMA) to Host RAM

- On-Board Memory: 16 MB DDR SDRAM Frame Buffer (Multi-Frame Capture Support)

- Triggering: External TTL Trigger Input, Software Trigger, Camera Trigger Output

- I/O Signals: 4x TTL Inputs (Camera Control), 4x TTL Outputs (Status/Control)

- Connectors: 1x 26-Pin SCSI-II (Camera Link), 1x 15-Pin D-Sub (I/O/Trigger)

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Power Consumption: 7W Typical, 10W Maximum (From PCI Bus)

- Isolation: 2500V AC Input-to-Chassis Isolation (I/O Lines)

- Software Compatibility: NI-IMAQ Driver, LabVIEW, Vision Development Module, C/C++, Windows 2000/XP/Vista/7 (32/64-Bit)

NI PCI-1424

Field Application & Problem Solved

In industrial manufacturing—automotive assembly lines, electronics PCB production, and packaging facilities—machine vision systems are the backbone of quality control, but connecting high-speed cameras to industrial PCs was a persistent headache before dedicated frame grabbers. Legacy solutions relied on parallel ports or low-bandwidth interfaces that dropped frames at high speeds, while generic frame grabbers lacked Camera Link compatibility or required CPU-intensive data transfer that slowed production lines. For example, an electronics factory inspecting 100 PCBs per minute needed to capture 12-bit monochrome images at 15 fps to detect solder bridges, but older interfaces couldn’t keep up—leading to missed defects and wasted product.

This Camera Link base frame grabber solves those issues by providing a dedicated, high-speed path between cameras and host PCs. You’ll find it in automotive plants verifying part placement on engine assemblies, electronics factories inspecting PCB solder joints and component alignment, and packaging facilities checking label accuracy and barcode readability. It’s also a critical component in legacy system upgrades—integrating with existing Camera Link cameras to add automated inspection without replacing expensive optics or rewiring production lines.

Its core value is reliable, real-time image acquisition that keeps pace with manufacturing speeds. The 85 MHz pixel clock handles high-frame-rate cameras, while DMA transfer offloads data processing from the CPU—ensuring the inspection system doesn’t bottleneck production. For plant managers, this means consistent defect detection and reduced waste; for test engineers, it’s a plug-and-play solution that integrates seamlessly with LabVIEW-based automation tools.

Installation & Maintenance Pitfalls (Expert Tips)

- Camera Link Cable Length & Quality: Camera Link Base cables are limited to 10 meters—exceeding this or using unshielded cables causes signal reflections and frame dropouts. I’ve seen a 12-meter cable in an automotive plant cause 30% frame loss; replacing it with a shielded 8-meter cable resolved the issue. For runs over 10 meters, use a Camera Link extender or fiber-optic adapter—don’t skimp on cable quality, as cheap cables introduce noise in industrial environments.

- Pixel Clock Mismatch: Rookies often assume the grabber will auto-negotiate pixel clock speed with the camera—this is a mistake. If the camera’s output clock exceeds the grabber’s 85 MHz limit (e.g., 100 MHz), images become corrupted or the system fails to acquire data. Use NI MAX to verify the camera’s pixel clock setting and match it to the grabber’s capabilities. In a PCB factory, a misconfigured 90 MHz clock caused “garbled image” errors until we adjusted the camera to 80 MHz.

- Insufficient Host RAM for Multi-Frame Capture: The 16 MB on-board buffer is temporary—continuous capture (e.g., 1 hour of inspection) requires sufficient host RAM to store images before processing. A packaging facility with 2 GB RAM experienced buffer overflow during 30-minute runs; upgrading to 4 GB RAM eliminated data loss. Calculate RAM needs upfront: a 10 MP 24-bit image = 30 MB per frame × 15 fps × 3600 seconds = 1.62 TB—use disk streaming for long-duration captures to avoid RAM exhaustion.

- Outdated NI-IMAQ Drivers: Legacy NI-IMAQ drivers (pre-4.0) don’t support 12-bit monochrome cameras or 64-bit OSes, and may cause communication failures with newer Camera Link modules. I’ve fixed countless “camera not detected” issues by updating to NI-IMAQ 5.0+—it includes bug fixes for high-temperature operation and improved compatibility with modern cameras. Even in legacy systems, updating drivers is critical—don’t assume “if it ain’t broke, don’t fix it” when dealing with vision system reliability.

NI PCI-1424

Technical Deep Dive & Overview

The PCI-1424’s performance is rooted in its dedicated Camera Link interface controller and DMA data transfer architecture. The Camera Link controller decodes the camera’s video stream (color or monochrome) and routes it to the 16 MB on-board frame buffer, which acts as a high-speed buffer to prevent frame drops during peak acquisition. This buffer is critical for handling transient speed bursts—e.g., when a production line speeds up temporarily—ensuring no images are lost.

DMA transfer is a game-changer for industrial applications: it bypasses the CPU, sending image data directly to host RAM. This eliminates the CPU bottleneck common with older frame grabbers, allowing the PC to run inspection software (e.g., LabVIEW Vision) simultaneously with data acquisition. For real-time defect detection, this means immediate pass/fail decisions—critical for stopping production when a defective part is detected.

The grabber’s support for 24-bit color and 8/10/12-bit monochrome makes it flexible across industries: color for label matching in packaging, high-bit-depth monochrome for solder joint contrast analysis in electronics. The 4x TTL inputs/outputs enable tight integration with industrial control systems—triggering image capture when a part enters the camera’s field of view (via a proximity sensor) and sending pass/fail signals to a PLC to divert defective parts.

Ruggedization features include 2500V AC isolation (protecting against voltage transients in factories) and an extended temperature variant (-40°C to 85°C) for unconditioned cabinets. While the PCI bus is aging, its 132 MB/s bandwidth is sufficient for Camera Link Base’s 255 Mbps data rate—making the PCI-1424 a reliable choice for legacy industrial PCs.

For field engineers, the PCI-1424’s biggest strength is its simplicity and compatibility. It works with thousands of Camera Link cameras, integrates seamlessly with LabVIEW, and requires minimal maintenance—making it a trusted component in critical quality control systems. It’s not the fastest frame grabber on the market, but it’s the one you can count on to keep production lines running and defects out of finished products.