Description

Key Technical Specifications

| Parameter | Details |

|---|---|

| Manufacturer | National Instruments (NI) |

| Bus Interface | PCI bus, plug-and-play compatible |

| Analog Input | 8 single-ended or 4 differential channels; 12-bit successive approximation ADC; maximum sampling rate of 100 ks/s; software-programmable voltage range (0 – 10V unipolar or ±5V bipolar) |

| Analog Output | 2 channels of 12-bit DAC; update rate between 20 s/s – 1 ks/s; resolution of 2.44 mv; supports independent configuration of unipolar/bipolar operation |

| Digital I/O | 24 TTL-compatible lines, can be configured as three 8-bit ports; supports input, output, bidirectional and handshake modes; maximum sink current of 2.5 ma per digital output line |

| Counters/Timers | 3 16-bit counters; maximum source frequency of 8 MHz, base clock frequency of 2 MHz; based on two 82C53 integrated circuits |

| Protection Performance | Analog input has ±35V overvoltage protection when powered on and ±25V when powered off; digital I/O has ±0.5V protection when powered off |

| Other Features | Self-calibration circuit for analog I/O; configuration parameters and calibration constants stored in EEPROM |

| Physical & Power | Weight 0.77kg, size 6.9×4.2 inches; 425ma current consumption at +5V DC; I/O connector is 50-pin male |

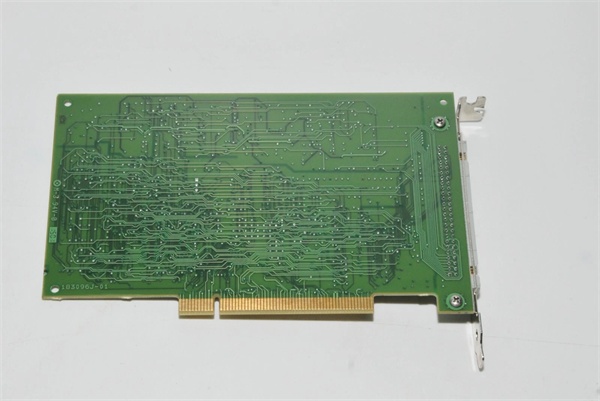

NI PCI-1200

Field Application & Problem Solved

In small and medium-sized laboratories, small production workshops and low-cost test projects, many users face the dilemma of balancing data acquisition needs and costs. High-end data acquisition cards are too expensive, while low-cost general-purpose cards often have single functions and poor stability. For example, in a university laboratory, students need to collect temperature and pressure signals in physics experiments, but they cannot afford high-priced professional equipment; in a small electronic component production workshop, it is necessary to monitor the voltage and current of the production line in real time and control the start and stop of small motors, but complex control systems are not cost-effective.

The NI PCI-1200 solves these problems with its multi-function integration and low-cost advantages. In university laboratories, it can connect temperature and pressure sensors to complete signal collection for student experiments, and cooperate with software to realize simple data analysis such as signal waveform display. In small workshops, it not only monitors the electrical parameters of the production line, but also controls the action of relays through digital I/O to realize the on-off control of the production line. In addition, it is also used in the development of small medical monitoring equipment to collect weak physiological signals such as human body micro-voltage, and provides analog output signals to drive the display of related instruments.

Its core value lies in the cost-effective integration of multiple functions. For users who do not require ultra-high sampling rate and high precision, it avoids the need to purchase multiple single-function modules, simplifies the system structure, reduces equipment costs and installation complexity.

Installation & Maintenance Pitfalls (Expert Tips)

- Ignoring Analog Input Wiring Differences: When switching between single-ended and differential analog input modes, incorrect wiring is a common mistake. For example, if differential wiring is used when the card is set to single-ended mode, signal crosstalk will occur. When collecting weak signals such as temperature sensors, differential wiring must be used to improve anti-interference ability, and the input lines should be kept away from power lines. A small workshop once had unstable temperature data collection, which was later found to be using single-ended wiring in a noisy environment; switching to differential wiring solved the problem.

- Overlooking Analog Output Update Rate Limitations: The analog output update rate of this card is up to 1 ks/s, which cannot meet the high-speed continuous output requirements. If it is used to drive high-speed actuators that require real-time parameter adjustment, it will cause control lag. A user once tried to use it to control the speed of a high-speed motor, resulting in unstable motor speed. Replacing it with a high-update-rate DAQ card or reducing the motor control frequency solved the problem.

- Digital I/O Current Overload: The maximum sink current of each digital output line is only 2.5 ma. Novices often directly connect high-power devices such as small fans to the digital I/O port, which will burn the I/O line. When controlling high-power equipment, a relay or solid-state relay must be added for current expansion. A laboratory once burned two digital ports due to directly connecting a 12V small fan; adding a relay module later avoided similar failures.

- Outdated Driver Compatibility Issues: The card has been discontinued by NI. Using it on Windows 10 and above systems with outdated NI-DAQ drivers will cause recognition failures or functional abnormalities. It is recommended to install a compatible version of the NI-DAQ driver (such as versions before NI-DAQmx 19.0). Many users have encountered the problem that the card cannot be recognized after system upgrade; downgrading the driver to a compatible version restored normal use.

NI PCI-1200

Technical Deep Dive & Overview

The NI PCI-1200 achieves a balance between cost and functionality through a streamlined hardware design. Its 12-bit successive approximation ADC meets the precision needs of most non-high-end test scenarios, and the 100 ks/s sampling rate is sufficient for low-frequency signal collection such as temperature, pressure and slow-changing voltage. The self-calibration circuit of analog I/O is a highlight. It can automatically compensate for offset and gain errors, avoiding the trouble of manual calibration for users and ensuring long-term stability of data.

In terms of data transmission, relying on the PCI bus, it can stably transmit the collected data to the host computer, which is more reliable than the early ISA bus. The 24-bit digital I/O lines and 3 counters/timers expand the application scenarios of the card. The counters can be used for event counting such as product counting on the production line and pulse width measurement, while the digital I/O can realize linkage control with other equipment.

Although compared with modern high-speed DAQ cards, its sampling rate and precision are not outstanding, and it only supports the outdated PCI bus (most new computers no longer have PCI slots), it still has irreplaceable value in legacy systems. A large number of small workshops and laboratories still use old industrial computers with PCI slots. The PCI-1200 can continue to play a role in these systems without the need to replace the entire control host, which greatly reduces the upgrade cost of the user’s system. For scenarios that do not pursue extreme performance, it is a practical and cost-effective data acquisition and control solution.