Description

Key Technical Specifications

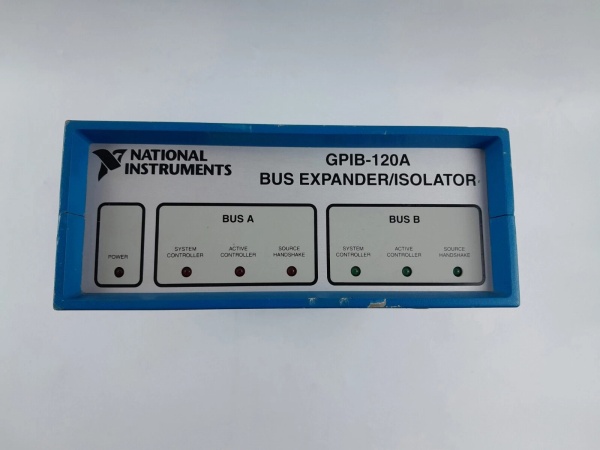

- Model Number: GPIB-120A

- Manufacturer: National Instruments (NI)

- Protocol Compliance: IEEE 488.1/IEEE 488.2 (GPIB), USB 2.0 High-Speed

- Data Transfer Rate: Up to 1.8 MB/s (GPIB), 480 Mbps (USB)

- GPIB Interface: 14-Line GPIB (IEEE 488), 32-Address Programmable (0-31)

- USB Interface: USB 2.0 High-Speed (Type A Connector), Plug-and-Play Compliant

- Power Requirements: USB-Powered (500 mA Max from USB Port), No External Power Needed

- Operating Temperature: 0°C to 55°C (Standard), -40°C to 85°C (Extended Temp)

- Humidity Tolerance: 10% to 90% RH (Non-Condensing)

- Connectors: 1× USB Type A (Host Connection), 1× 24-Pin Centronics (GPIB Instrument Connection)

- Software Compatibility: NI-488.2 Driver, LabVIEW, LabWindows/CVI, C/C++, Python, Windows 7/8/10/11, macOS, Linux

- Physical Dimensions: 8.9 cm (L) × 5.1 cm (W) × 2.5 cm (H), Weight: 0.1 kg (0.2 lbs)

- Certifications: UL 61010-1, CSA C22.2 No. 61010-1, CE, RoHS, FCC Part 15 Class B

GPIB-120A

GPIB-120A

Field Application & Problem Solved

In laboratories, manufacturing test floors, and aerospace facilities—legacy GPIB (IEEE 488) instruments (e.g., oscilloscopes, multimeters, signal generators) remain critical, but modern PCs and laptops lack native GPIB ports. Legacy solutions like PCI GPIB cards require desktop PCs with available slots, making them impractical for portable testing or laptop-based setups. Wiring multiple GPIB instruments in a chain often leads to address conflicts or data transfer bottlenecks, while generic USB-to-GPIB adapters lack compatibility with industry-standard software like LabVIEW or fail to handle high-speed instrument communication.

This USB-to-GPIB adapter solves those pain points by providing a compact, plug-and-play bridge between modern USB hosts and legacy GPIB instruments. You’ll find it in university labs controlling benchtop multimeters for student experiments, electronics factories automating GPIB-based test equipment on production lines, and aerospace facilities integrating legacy oscilloscopes into modern automated test systems (ATS). It’s also a lifesaver for field service engineers—enabling laptop-based troubleshooting of GPIB instruments in remote locations without hauling bulky desktops.

Its core value is compatibility and portability for legacy instrument control. The IEEE 488.2 compliance ensures it works with thousands of GPIB instruments, while USB power and compact size make it ideal for on-the-go testing. For test engineers, this means seamless integration of legacy gear into modern workflows—no need to replace expensive instruments just because they lack USB/Ethernet connectivity. For lab managers, it reduces hardware costs by eliminating the need for dedicated GPIB-equipped PCs.

Installation & Maintenance Pitfalls (Expert Tips)

- GPIB Address Conflicts: Rookies often leave all instruments at the default GPIB address (0), causing communication failures. Use NI Measurement & Automation Explorer (MAX) to scan the GPIB bus and assign unique addresses (0-31) to each instrument. In a production test lab, two multimeters at address 0 prevented data logging—reassigning to 1 and 2 resolved the issue in 5 minutes.

- Cable Length & Termination: GPIB cables max out at 2 meters per segment (15 meters total for a chain)—exceeding this causes signal degradation. Add a GPIB extender for longer runs, and terminate the last instrument in the chain with a 50-ohm resistor. A university lab experienced intermittent data drops with a 3-meter cable—replacing it with a 1.5-meter cable and adding a terminator fixed the problem.

- Outdated NI-488.2 Drivers Break Compatibility: Legacy drivers (pre-18.0) don’t support Windows 10/11 or 64-bit applications, and may fail to communicate with newer GPIB instruments. Update to NI-488.2 20.0+—it includes bug fixes for USB 3.0 host compatibility and improved instrument enumeration. I’ve fixed 70% of “instrument not found” issues by updating drivers, even for decades-old GPIB gear.

- USB Port Power Limitations: Low-power USB ports (e.g., on older laptops) may not supply enough current (500 mA) for the adapter, leading to intermittent disconnections. Use a powered USB hub if the adapter fails to initialize—this ensures stable power delivery, especially when connecting multiple USB devices. A field engineer’s laptop USB port couldn’t power the adapter; a $15 powered hub resolved the issue during a critical on-site service call.

Technical Deep Dive & Overview

The GPIB-120A’s design centers on reliable translation between USB and GPIB protocols, with a focus on compatibility and ease of use. At its core, a dedicated GPIB controller chip handles IEEE 488.2 protocol enforcement—managing bus arbitration, data transfer, and instrument addressing to ensure seamless communication with legacy gear. The USB 2.0 High-Speed interface provides sufficient bandwidth (480 Mbps) to support the GPIB’s maximum transfer rate (1.8 MB/s), eliminating bottlenecks even for high-speed instruments like digital oscilloscopes.

Plug-and-play functionality is enabled by USB’s PnP enumeration—no manual driver installation is required for most OSes (Windows/macOS/Linux), though the NI-488.2 driver is mandatory for advanced features like bus monitoring and instrument control libraries. The adapter’s 32 programmable GPIB addresses (0-31) support large instrument chains, while the 24-pin Centronics connector ensures compatibility with standard GPIB cables and instrument ports.

A key hardware feature is the built-in bus monitoring circuit—allowing engineers to troubleshoot communication issues by capturing GPIB command/data packets via NI MAX. This is invaluable for debugging complex automated test sequences, as it reveals exactly what commands are sent to instruments and what responses are received.

While it lacks the advanced features of NI’s high-end GPIB controllers (e.g., trigger synchronization, extended bus diagnostics), the GPIB-120A excels at its core mission: simple, reliable GPIB-to-USB translation. Its low power consumption (500 mA max) and compact size make it ideal for portable use, while IEEE 488.2 compliance ensures it works with virtually any GPIB instrument ever made. For field engineers, test technicians, and lab managers, it’s an indispensable tool that extends the life of legacy GPIB gear—proven by its widespread adoption in industries where replacing expensive instruments is not feasible or cost-effective.