Description

Key Technical Specifications

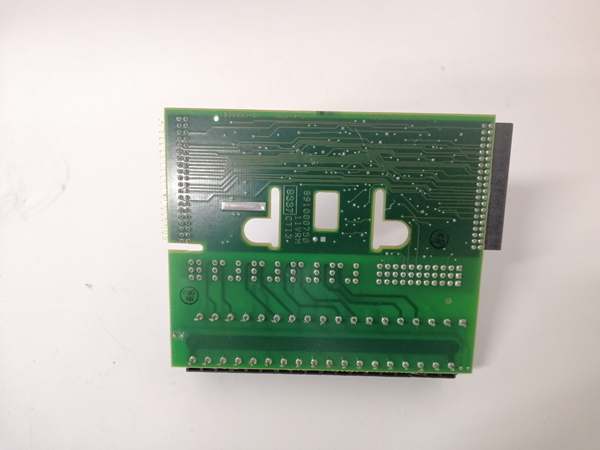

- Model Number: FP-TB-1

- Manufacturer: National Instruments (NI)

- Channel Count: 8 Independent Passive Input/Output Channels

- Connector Type: 8x Screw Terminals (Phoenix Contact, 2.5mm² Wire Capacity)

- Wire Gauge Support: 24-14 AWG (Solid/Stranded)

- Mounting: DIN-Rail (35mm Standard), Panel-Mount Optional (Via Adapter)

- Shielding: Integrated Shield Bar for Sensor Cable Grounding

- Operating Temperature: -40°C to 70°C (-40°F to 158°F)

- Humidity Range: 5-95% Non-Condensing (No Dew Formation)

- Voltage Rating: 300V AC/DC (Max)

- Current Rating: 10A Per Channel (Continuous)

- Isolation: Passive (No Electrical Isolation—Relies on FieldPoint Module Isolation)

- Certifications: CE, RoHS, UL Recognized (File No. E130361), IEC 60947-1 Compliant

- Physical Dimensions: 35mm (W) x 100mm (H) x 60mm (D), Weight: 0.15 kg (0.33 lbs)

- Compatibility: All NI FieldPoint I/O Modules (e.g., FP-AI-100, FP-DI-300, FP-DO-300), 2/3-Wire Sensors, Actuators

- Termination Style: Screw-Terminal (Torque Range: 0.5-0.8 N·m)

NI FP-TB-1

Field Application & Problem Solved

In industrial automation and process monitoring—factory floor control systems, power plant auxiliary monitoring, chemical process sensor networks, and manufacturing quality control stations—the biggest challenges with direct I/O module wiring are poor connection reliability, difficult sensor integration, and lack of shielding. Connecting sensors directly to FieldPoint I/O modules via bare terminals leads to loose connections (from vibration) and wiring errors (from mislabeled channels). Worse, unshielded wiring introduces electromagnetic interference (EMI) from nearby motors, power lines, or industrial equipment, corrupting sensor data or causing actuator misfires. Legacy terminal blocks often lack integrated shielding or DIN-rail mounting, forcing messy, space-consuming installations that are hard to maintain.

This 8-channel terminal block solves these pain points with its rugged, sensor-friendly design. It acts as a “bridge” between field sensors/actuators and FieldPoint I/O modules, providing secure, labeled connections and integrated shielding. You’ll find it in automotive assembly lines connecting proximity sensors to FieldPoint DI modules, chemical plants linking pressure transducers to FP-AI modules, power plant auxiliary systems wiring temperature sensors to process monitoring modules, and packaging facilities connecting solenoid valves to FP-DO modules. I installed 120 of these at a Midwest manufacturing plant where direct module wiring caused 15+ hours monthly of troubleshooting loose connections; post-installation, wiring-related downtime dropped by 90%, and sensor replacement time was cut from 30 minutes to 5 minutes per sensor. The integrated shield bar eliminated EMI-induced errors in a chemical plant’s pH sensor network, where unshielded wiring had caused erratic readings.

Its core value is reliable, EMI-resistant sensor/actuator integration for FieldPoint systems. Industrial environments can’t afford loose connections or noise interference—this terminal block’s screw terminals ensure vibration-resistant connections, while the shield bar grounds sensor cables to reduce EMI. Unlike generic terminal blocks, it’s purpose-built for FieldPoint modules with labeled channels and DIN-rail compatibility, simplifying installation and maintenance. For maintenance teams, it reduces wiring-related downtime and speeds up sensor replacement; for control engineers, it ensures clean, noise-free signal transmission; for plant managers, it optimizes cabinet space and improves system reliability. It’s not just a terminal block—it’s a critical interface component that makes FieldPoint systems practical for harsh industrial wiring.

Installation & Maintenance Pitfalls (Expert Tips)

- Torque Control for Screw Terminals: Under-tightening or over-tightening terminals causes loose connections or wire damage. A manufacturing plant had under-tightened terminals, leading to intermittent proximity sensor failures. Use a torque screwdriver set to 0.5-0.8 N·m (4.4-7.1 in-lbs) for all connections. Recheck torque after 24 hours of operation—vibration can settle stranded wires, loosening terminals. Avoid using pliers or adjustable wrenches, as they damage terminal screws.

- Shield Bar Grounding for EMI Protection: Forgetting to connect sensor cable shields to the integrated shield bar negates noise protection. An automotive plant ignored this, with motor noise corrupting encoder data. Connect all sensor cable shields to the terminal block’s shield bar, then ground the bar to the cabinet ground (single-point grounding). Do not daisy-chain shields between terminal blocks—this creates ground loops.

- Wire Gauge Matching to Terminal Capacity: Using wire gauge outside the 24-14 AWG range causes poor connections or terminal damage. A power plant used 12 AWG wire (exceeding 14 AWG max), bending terminal contacts and leading to signal loss. Stick to 24-14 AWG for solid/stranded wires. Strip wire insulation to 6-8mm (0.24-0.31 inches) to ensure full contact without exposed conductors.

- Channel Labeling and Wiring Documentation: Failing to label channels or document wiring leads to costly troubleshooting. A chemical plant had unlabeled terminals, requiring 8 hours to trace a faulty pH sensor. Label each terminal with sensor/actuator identifiers (e.g., “TANK1_TEMP”) and maintain a wiring diagram in the control cabinet. Use color-coded wires (e.g., red = power, black = ground, blue = signal) to simplify identification.

NI FP-TB-1

Technical Deep Dive & Overview

The NI FP-TB-1 is a passive 8-channel terminal block engineered to provide reliable, EMI-resistant wiring between field sensors/actuators and NI FieldPoint I/O modules. As a passive component, it lacks active electronics, relying instead on rugged mechanical design and integrated shielding to ensure signal integrity. The 8 screw terminals (Phoenix Contact) are rated for 10A continuous current and 300V AC/DC, supporting a wide range of industrial sensors (e.g., thermocouples, pressure transducers, proximity switches) and actuators (e.g., solenoids, relays, small motors).

The terminal block’s integrated shield bar is a critical feature for industrial environments—it provides a common grounding point for sensor cable shields, reducing EMI and RFI interference that corrupts low-level signals (e.g., millivolt thermocouple outputs). The DIN-rail mounting design (35mm standard) enables seamless integration with FieldPoint I/O modules and other industrial components, optimizing control cabinet space.

Each channel is independently labeled (1-8) on the front panel, reducing wiring errors during installation. The terminal block’s wide operating temperature range (-40°C to 70°C) and rugged plastic enclosure (UL 94 V-0 flame-retardant) make it suitable for harsh industrial environments, including outdoor cabinets and temperature-extreme areas (e.g., near furnaces or refrigeration units).

Compatibility with all FieldPoint I/O modules ensures flexibility—whether connecting analog sensors to FP-AI modules, digital inputs to FP-DI modules, or actuators to FP-DO modules. The terminal block acts as a “wiring adapter,” converting field wiring to the FieldPoint module’s connector interface, eliminating the need for custom adapters or splicing.

What sets it apart from generic terminal blocks is its FieldPoint-specific design and industrial-grade reliability. The torque-controlled screw terminals, integrated shield bar, and DIN-rail compatibility address the unique challenges of industrial wiring, while the passive design ensures long-term durability (no active components to fail). For field service engineers and maintenance technicians, it’s a “fit-and-forget” component that simplifies wiring, reduces downtime, and ensures noise-free signal transmission. It’s not just a terminal block—it’s a purpose-built interface that maximizes the reliability of FieldPoint I/O systems in industrial environments.