Description

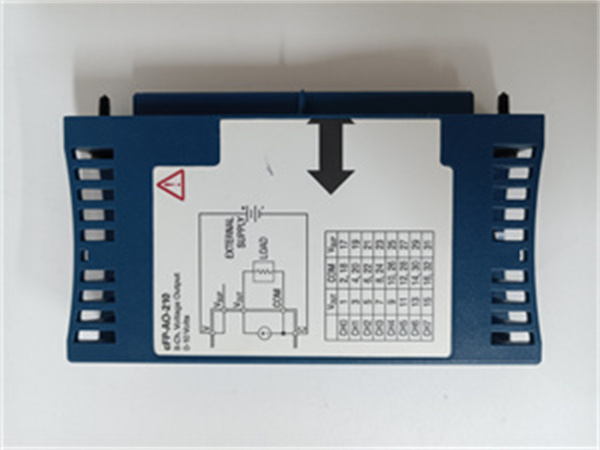

NI CFP – AO – 210 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | CFP – AO – 210 |

| Manufacturer | National Instruments |

| Product category | Compact FieldPoint analog voltage output module |

| Channels | 8 voltage output channels |

| Resolution | 12 – bit |

| Output ranges | 0 – 10 V (with an over – ranging value of 0.2 V, so the actual full – scale range is 0 – 10.2 V) |

| Output impedance | Not specified in some sources, but typical values for such modules are low (e.g., a few ohms) |

| Update rate | 200 Hz for all channels |

| Output current per channel | Up to 1 mA without external supply; can reach up to 10 mA with an optional 15 – 30 VDC external power supply |

| Over – ranging feature | 0.2 V over – ranging for each channel to account for field device errors |

| Monitoring circuit | Each channel has a circuit to detect current flowing in or out of the channel. Alerts and adjusts output if current exceeds limits (1 mA without external supply, 10 mA with external supply) |

| Slew rate | 0.5 V/µs |

| Status indicators | Red status LEDs for each channel to indicate current – limit violations |

| Physical dimensions | 5.00 x 2.60 x 0.94 inches (127 x 66.04 x 23.88 mm) and weighs 4.1 oz (116.23 g) |

| Operating temperature | – 40 °C to 70 °C |

| Storage temperature | – 55 °C to 100 °C |

| Relative humidity | Not specified in all sources, but typical industrial – grade modules can handle 10 – 90% non – condensing |

| Operating vibrations (random/sinusoidal) | 5 grms / 5 g (10 Hz – 500 Hz) |

| Compliance standards | Meets relevant industry standards for electrical safety and electromagnetic compatibility. Comes with NIST – traceable calibration certificates |

NI CFP-AO-210

Product introduction

The National Instruments CFP – AO – 210 is a high – performance 8 – channel analog voltage output module tailored for Compact FieldPoint systems. It serves as a crucial component for converting digital control signals into precise analog voltage outputs, making it an essential part of industrial control, automation, and monitoring applications.

As part of the Compact FieldPoint family, the CFP – AO – 210 combines reliability, flexibility, and ease of use. Its 12 – bit resolution ensures accurate voltage output levels, which are vital for controlling various industrial actuators, valves, and gauges. The module offers a standard output range of 0 – 10 V per channel, with an additional 0.2 V of over – ranging capacity. This over – ranging feature allows for compensation of length and balance errors in field devices, enhancing the overall accuracy of the control system. With a 200 Hz update rate for all channels, the CFP – AO – 210 can respond quickly to changes in control signals, making it suitable for applications where real – time control is required. It also comes equipped with built – in monitoring circuits for each channel and on – board diagnostics, ensuring trouble – free operation and simplifying maintenance.

Core advantages and technical highlights

Precise voltage output with 12 – bit resolution

The 12 – bit resolution of the NI CFP – AO – 210 enables it to generate highly accurate analog voltage signals. This level of precision is crucial in applications where fine – grained control is necessary, such as in precision manufacturing processes. For example, in a semiconductor manufacturing plant, the CFP – AO – 210 can be used to control the voltage applied to wafer – handling robots with great accuracy. The small voltage steps provided by the 12 – bit resolution ensure that the robots move smoothly and precisely, reducing the risk of damaging delicate semiconductor wafers. In medical equipment, such as infusion pumps, the accurate voltage output can be used to control the flow rate of medications with high precision, ensuring patient safety.

Multiple output ranges and over – ranging capabilities

With an output range of 0 – 10 V per channel and an over – ranging value of 0.2 V, the CFP – AO – 210 offers flexibility in handling different types of loads and compensating for errors in the field. In industrial settings, many sensors and actuators have nominal operating ranges within this spectrum. The over – ranging feature is particularly useful when dealing with long cable runs or when the connected devices have small inherent errors. For instance, in a large – scale industrial plant with extensive wiring, the over – ranging can account for voltage drops along the cables, ensuring that the actuators receive the correct voltage for proper operation. This eliminates the need for complex external circuitry to adjust for these errors, reducing system complexity and cost.

High update rate and fast slew rate

The 200 Hz update rate for all channels means that the CFP – AO – 210 can quickly adapt to changes in the digital control signals. In fast – paced industrial processes, such as high – speed packaging lines, the module can rapidly adjust the voltage outputs to control the speed and position of conveyor belts and packaging machinery. The fast slew rate of 0.5 V/µs ensures that the voltage transitions are smooth and rapid, minimizing any potential glitches or overshoots in the output signal. This is important in applications where sudden changes in voltage could cause mechanical stress or inaccurate operation of the connected devices. For example, in a servo – motor control system, the fast slew rate allows for quick and precise changes in the motor’s speed and direction, enabling smooth and efficient motion control.

Built – in monitoring and diagnostic features

Each channel of the CFP – AO – 210 is equipped with a monitoring circuit that detects the current flowing in or out of the channel. If the current exceeds the maximum allowable value (1 mA without external supply or 10 mA with external supply), the module takes immediate action. It lights a red status LED for the affected channel, reports the error to the system module, and adjusts the output voltage to limit the current to the maximum permitted value. This proactive approach to fault detection and correction helps in preventing damage to the connected devices and ensures the continuous operation of the control system. In a complex industrial automation system, these diagnostic features can significantly reduce downtime by quickly identifying and resolving issues related to over – current conditions.

Typical application scenarios

In industrial automation, the NI CFP – AO – 210 is widely used to control a variety of actuators. In a manufacturing plant, it can be used to control pneumatic and hydraulic valves that regulate the flow of fluids in production processes. For example, in a food and beverage factory, the CFP – AO – 210 can adjust the opening and closing of valves in the filling and bottling lines, ensuring accurate filling levels. It can also control the speed of motors driving conveyor belts, allowing for smooth and efficient material handling. In a chemical processing plant, the module can be used to control the temperature and pressure of reactors by adjusting the voltage applied to heating elements and pressure regulators.

In environmental control systems, the CFP – AO – 210 plays a vital role. In a large – scale greenhouse, it can be used to control the opening and closing of vents and shades based on temperature, humidity, and light sensors. By accurately adjusting the voltage outputs, the module can maintain optimal environmental conditions for plant growth. In a building’s HVAC (Heating, Ventilation, and Air Conditioning) system, the CFP – AO – 210 can control the speed of fans and the opening of dampers, regulating the indoor temperature and air quality. This helps in energy conservation and providing a comfortable indoor environment for occupants.

In test and measurement applications, the module is used to generate precise analog signals for calibrating and testing other devices. In a calibration laboratory, the CFP – AO – 210 can be used to generate known voltage signals to calibrate voltage – measuring instruments such as multimeters and oscilloscopes. In a product testing facility, it can be used to simulate real – world input signals for testing the performance of sensors and control systems. For example, in the testing of automotive sensors, the CFP – AO – 210 can generate voltage signals that mimic the outputs of sensors in different driving conditions, allowing manufacturers to verify the accuracy and reliability of their products.

NI CFP-AO-210

Related model recommendations

CFP – AI – 111: As described earlier, this 16 – channel analog current input module can be paired with the CFP – AO – 210 in systems where both analog input and output are required. In a closed – loop control system, the CFP – AI – 111 can measure the current from sensors, and the CFP – AO – 210 can generate analog voltage signals to control actuators based on the measured data. For example, in a temperature – controlled system, the CFP – AI – 111 can measure the current from a temperature sensor, and the CFP – AO – 210 can control the power supplied to a heating or cooling element.

Compact FieldPoint Chassis: Appropriate Compact FieldPoint chassis, like the CFP – 2020, are necessary to house the CFP – AO – 210 and other compatible modules. The chassis provides power, communication interfaces, and mechanical support, enabling seamless integration into a complete Compact FieldPoint system.

LabVIEW: NI’s LabVIEW software is a powerful tool for programming and controlling the CFP – AO – 210. It offers a graphical programming environment with pre – built functions for data acquisition, signal processing, and device control. LabVIEW simplifies the development of applications that utilize the CFP – AO – 210, allowing engineers to quickly create custom control systems. For example, engineers can use LabVIEW to create user – friendly interfaces for monitoring and adjusting the voltage outputs of the CFP – AO – 210.

NI – DAQmx: This driver software is essential for communicating with the CFP – AO – 210. It provides a standardized interface for configuring the module, generating output signals, and handling errors. NI – DAQmx is compatible with various programming languages, including C, C++, and Python, giving developers flexibility in choosing the programming environment for their applications.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI CFP – AO – 210, ensure that the Compact FieldPoint system is powered off. Use an anti – static wristband to handle the module to prevent electrostatic discharge damage to the sensitive electronics. Verify that the Compact FieldPoint chassis has an available slot that is compatible with the CFP – AO – 210. Connect the appropriate cables to the module’s output terminals, making sure that the wiring is correct for the intended application. Since the module has 8 voltage output channels, take care to label and connect the cables correctly to the corresponding channels. Mount the module in the chassis and secure it using the provided hardware. After installation, power on the Compact FieldPoint system.

Commissioning

Install the NI – DAQmx driver software on the host computer that is connected to the Compact FieldPoint system. Use the NI – MAX (Measurement & Automation Explorer) utility to configure the CFP – AO – 210. Set the output ranges for each channel according to the requirements of the connected devices. If an external power supply is used to increase the output current, ensure that it is properly configured. Calibrate the module using NI’s calibration utility to ensure accurate voltage outputs. This calibration may involve measuring the actual voltage outputs at known settings and adjusting the module’s internal parameters if necessary. Test the module by generating test signals from the host system and verifying that the correct voltage levels are outputted on each channel. If using LabVIEW, create a simple control VI (Virtual Instrument) to start adjusting and monitoring the voltage outputs of the CFP – AO – 210.

Maintenance suggestions

Regularly inspect the module’s connectors for any signs of corrosion, loose connections, or physical damage. Corrosion can affect the electrical conductivity and lead to inaccurate voltage outputs. If any issues are detected, clean the connectors using a suitable contact cleaner. Monitor the status LEDs on the module. The red status LEDs should only light up in case of over – current conditions. If a red LED is constantly on or blinking, check the connected loads and the module configuration to ensure that the current levels are within the specified limits. Calibrate the CFP – AO – 210 periodically, following NI’s recommended calibration intervals, to maintain voltage output accuracy. In case of a suspected module failure, use the on – board diagnostics and NI – MAX to troubleshoot the issue. If the problem persists, contact NI’s technical support for further assistance.

Service and guarantee commitment

The NI CFP – AO – 210 typically comes with a standard warranty, which covers defects in materials and workmanship for a specified period, usually 1 – 3 years depending on the region and purchase terms. NI’s global technical support team is available to provide assistance for installation, configuration, and troubleshooting. They can be reached via phone, email, or online support forums. NI also offers calibration services, either on – site or at their accredited calibration facilities, to ensure that the module continues to meet its specified accuracy requirements. For customers with complex or custom applications, NI’s professional services team can provide consulting, system integration, and software development services to optimize the use of the CFP – AO – 210 in their specific systems.