Description

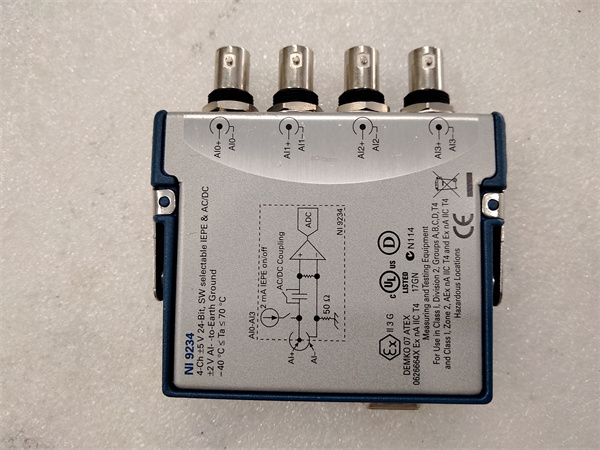

NI-9234 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI-9234 |

| Manufacturer | NI |

| Product category | C Series Sound and Vibration Input Module |

| Number of Input Channels | 4 (Simultaneously Sampled) |

| Resolution | 24-bit |

| Maximum Sampling Rate per Channel | 51.2 ks/s |

| Input Voltage Range | ±5 V |

| Sensor Compatibility | Integrated Electronic Piezoelectric (IEPE) and non – IEPE sensors (e.g., accelerometers, tachometers, proximity probes), Smart TEDS sensors |

| Coupling Options | Software – selectable AC/DC coupling |

| IEPE Signal Conditioning | Yes (Software – selectable for each channel) |

| Anti – aliasing Filters | Built – in, automatically adjust to sample rate |

| Dynamic Range | 102 dB |

| Shock Resistance | 50 g |

| Vibration Resistance | 5 g |

| Weight | 6.1 oz (173 g) |

| Part Numbers | 779680 – 01 (Non – conformal coated), 779680 – 03 (Conformal coated) |

| Connector Type | Four BNC connectors for signal input |

| Platform Compatibility | CompactDAQ, CompactRIO, Single – module USB carrier (NI USB – 9162) |

NI-9234

Product introduction

The NI-9234 is a high – performance C Series sound and vibration input module by NI, designed to meet the exacting requirements of various industries for accurate and reliable signal measurement. This module is a cornerstone in applications where precise monitoring and analysis of sound and vibration signals are crucial.

Featuring four simultaneously sampled analog input channels, the NI – 9234 can capture multiple signals at once, ensuring comprehensive data collection. With a 24 – bit resolution, it offers a high level of precision in measuring signals from a wide range of sensors. It is compatible with both integrated electronic piezoelectric (IEPE) and non – IEPE sensors, such as accelerometers for measuring vibrations, tachometers for rotational speed sensing, and proximity probes for detecting the proximity of objects. The module also supports Smart TEDS sensors, which can store calibration and identification data, streamlining the sensor setup process. Its software – selectable AC/DC coupling and IEPE signal conditioning for each channel provide users with the flexibility to adapt to different measurement scenarios.

Core advantages and technical highlights

High – Resolution Signal Measurement: The 24 – bit resolution of the NI – 9234 enables it to measure signals with exceptional accuracy, detecting even the slightest changes in sound and vibration. This high resolution is especially important in applications where small signal variations carry significant information, such as in precision machinery condition monitoring or in acoustic research for detecting subtle sound patterns.

Simultaneous Multi – Channel Sampling: The ability to sample four channels simultaneously ensures that correlated signals can be captured accurately. In applications like multi – axis vibration analysis in industrial machinery or in vehicle noise, vibration, and harshness (NVH) testing, where multiple sensors are used to measure different aspects of a system’s behavior, the simultaneous sampling feature of the NI – 9234 helps in obtaining synchronized data for comprehensive analysis.

Versatile Sensor Compatibility: The module’s compatibility with a wide variety of sensors, including both IEPE and non – IEPE types, makes it a versatile choice for different applications. Whether it’s connecting to accelerometers in a manufacturing plant to monitor equipment health or using proximity probes in a research laboratory to study mechanical interactions, the NI – 9234 can interface with these sensors seamlessly. The support for Smart TEDS sensors further simplifies the sensor integration process, as the module can automatically access the sensor’s calibration and identification information.

Advanced Signal Conditioning: The software – selectable AC/DC coupling and IEPE signal conditioning allow users to optimize the module for specific measurement requirements. For example, in applications where only the alternating current (AC) component of a signal is of interest, such as in measuring the vibration of a rotating machine where the DC offset is not relevant, the AC coupling can be selected. On the other hand, for applications that require measuring the DC component or a combination of AC and DC, the DC coupling option is available. The software – selectable IEPE signal conditioning is useful when connecting to IEPE sensors, as it can be enabled or disabled for each channel as needed.

Automatic Anti – aliasing Filters: The built – in anti – aliasing filters that automatically adjust to the user – specified sampling rate are a significant advantage. Anti – aliasing filters prevent high – frequency signals from being misinterpreted as lower – frequency signals, which can occur when the sampling rate is not high enough. By automatically adjusting to the sampling rate, the NI – 9234 ensures that the measured signals are accurate and free from aliasing artifacts, regardless of the sampling rate chosen by the user.

Typical application scenarios

In industrial machine condition monitoring, the NI – 9234 plays a vital role. By connecting accelerometers to the module, it can continuously monitor the vibration levels of industrial machinery such as motors, pumps, and compressors. Any abnormal vibrations can be detected early, allowing for preventive maintenance and reducing the risk of unexpected equipment failures. This helps in improving the overall efficiency and reliability of industrial production processes.

In automotive NVH testing, the module is extensively used. It can be connected to multiple sensors placed at different locations in a vehicle, such as on the engine, suspension, and body panels. The NI – 9234 then measures the vibrations and sounds generated during vehicle operation. This data is used by automotive engineers to optimize the vehicle’s design, reducing noise and vibrations to improve the overall driving experience.

In research laboratories, especially those focused on acoustics and mechanical engineering, the NI – 9234 is an essential tool. In acoustic research, it can be used to measure sound pressure levels and analyze the frequency content of sounds. In mechanical engineering research, it can be used to study the dynamic behavior of structures under different loading conditions by measuring vibrations. The high – resolution and versatile signal – handling capabilities of the module make it suitable for such in – depth research applications.

NI-9234

Related model recommendations

NI – 9233: Belongs to the same family of sound and vibration input modules. While it has similar features to the NI – 9234, the NI – 9233 has a lower maximum sampling rate of 50 ks/s compared to the NI – 9234’s 51.2 ks/s. Additionally, the NI – 9233 has a non – linear phase characteristic, which may cause relative phase differences between different frequency components of a signal. It is suitable for applications where the sampling rate and phase linearity requirements are not as strict, such as some basic machinery vibration monitoring in less – critical industrial settings.

NI – 9237: Another module in the series. It also has a maximum sampling rate of 50 ks/s. The NI – 9237 may be a better choice in applications where the specific features it offers, such as its particular synchronization capabilities or its performance in certain environmental conditions, are more relevant. For example, in a multi – module setup where the synchronization requirements are different from what the NI – 9234 can provide, the NI – 9237 might be considered.

NI – 9229: This module has different input characteristics and capabilities. It has a lower resolution compared to the NI – 9234. However, it may be suitable for applications where the measurement requirements are less demanding in terms of resolution, but other features like its input voltage range or its compatibility with specific types of sensors are more important. For instance, in some applications where cost – effectiveness is a major factor and the lower resolution can still meet the measurement accuracy needs, the NI – 9229 could be a viable alternative.

NI – 9239: Similar to the NI – 9234 in some aspects, but with its own unique set of features. It might have different performance characteristics in terms of noise rejection or its response to certain types of signals. In applications where these specific performance aspects are crucial, such as in high – noise environments where the NI – 9239’s noise rejection capabilities are better suited, it can be considered instead of the NI – 9234.

NI – USB – 9234: This is a USB – connected version of the sound and vibration input module. It combines the NI – 9234 module with an NI USB – 9162 carrier. The main advantage of the NI – USB – 9234 is its portability and ease of connection to a computer via USB. It is ideal for applications where mobility is required, such as in field – based vibration and sound measurements or in test setups where quick reconfiguration is needed.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI – 9234, ensure that the host system, whether it’s a CompactDAQ, CompactRIO, or a system with an NI USB – 9162 carrier, is properly configured and powered off. The installation environment should be clean, free from excessive dust, and have minimal electromagnetic interference. When handling the module, use anti – static precautions, such as wearing an anti – static wrist strap, to prevent electrostatic discharge from damaging the sensitive components. For the NI – USB – 9234, make sure the computer has a compatible USB port.

Commissioning: Install the NI – DAQmx 9.2 or later driver software on the host system before using the NI – 9234. After the driver installation, install support for the preferred application development environment, which could be LabVIEW, LabWindows/CVI, C/C++, C#, or Visual Basic.NET. Connect the appropriate sensors to the four BNC connectors on the module, ensuring proper signal connections. Power on the system and use the installed software to configure the module settings, such as the sampling rate, coupling type, and sensor type. Test the module by acquiring sample signals and verifying that the data is being captured correctly.

Maintenance suggestions: For daily maintenance, regularly check the connections of the cables attached to the NI – 9234 to ensure they are secure. Monitor the data acquisition performance and look for any signs of abnormal noise, incorrect signal levels, or data dropouts. In case of issues, first check the software configuration settings to ensure they are correct for the specific application. If a hardware problem is suspected, check for any visible signs of damage to the module or the connectors. If a hardware replacement is needed, follow the installation steps in reverse. Update the NI – DAQmx driver software regularly as per NI’s recommendations to ensure compatibility with the latest software and hardware, and to access any new features or performance improvements.

Service and guarantee commitment

NI stands firmly behind the quality of the NI – 9234. The product comes with a comprehensive quality assurance program. In case of any manufacturing defects, NI offers replacement or repair services within the warranty period. Their dedicated technical support team is available to assist customers with any installation, configuration, or performance – related queries. Whether it’s helping with integrating the module into a complex system, troubleshooting data acquisition issues, or providing guidance on sensor selection, NI’s experts are accessible via various channels. This commitment to quality and after – sales service reflects NI’s confidence in the NI – 9234 and their responsibility to ensure customers can fully utilize this high – performance sound and vibration input module in their applications.