Description

Detailed parameter table

| Parameter name | Parameter value |

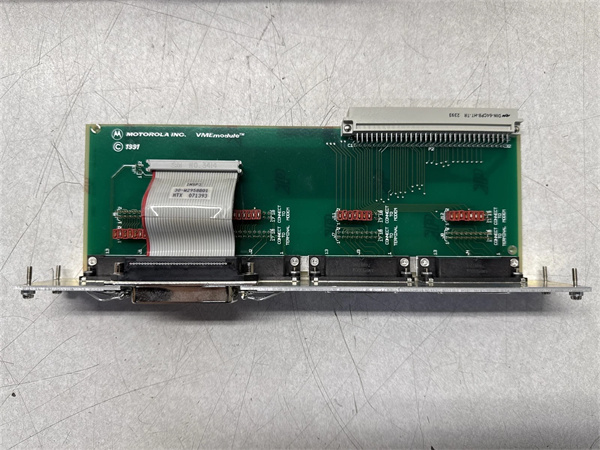

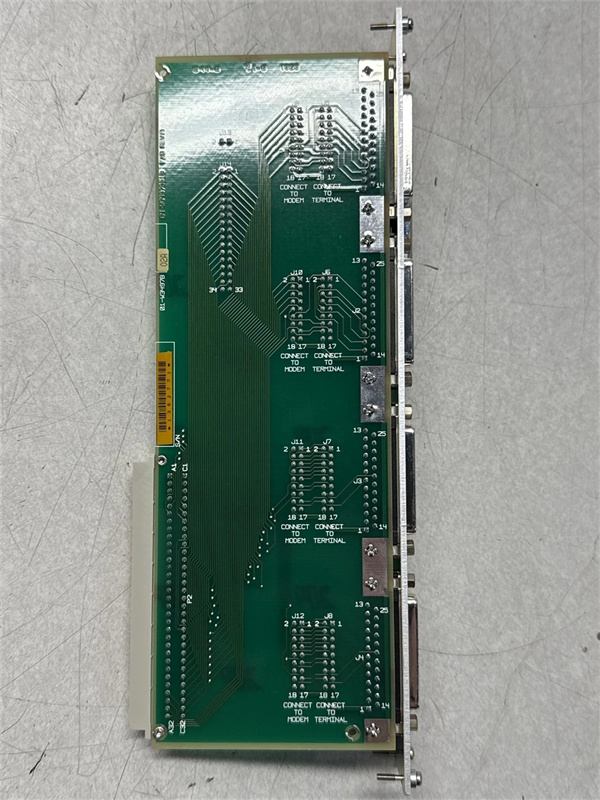

| Product model | Motorola MVME715P |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged VMEbus Rear I/O Transition Module for Industrial Peripheral Integration |

| Interface Configuration | 4x EIA-232-D/422/485 serial ports (DB25, isolated); 2x 10/100Base-T Ethernet ports (RJ45, isolated); 1x Centronics-compatible parallel port (DB25); 1x SCSI-2 interface (vibration-resistant); 2x USB 1.1 ports (for diagnostic tools); VMEbus rear-panel connector (for SBC/I/O module integration) |

| VMEbus Compliance | VMEbus Rev C/D; Slave-only operation; A16/A24 addressable; Interrupt support: 4 programmable levels (for serial/Ethernet activity); Max data transfer rate: 12 MB/s (compatible with VME64x) |

| Electromagnetic Protection | Front-panel RFI/EMI shielding (FCC Class B compliance); ESD protection (±15 kV contact, ±25 kV air) for all external ports; Surge protection (2 kV) for Ethernet/serial ports |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 254 mm (D); weight: ~650 g; Reinforced conformal coating (IPC-CC-830 Class 3); Gold-plated edge connectors (200 microinches, corrosion-resistant); Metal EMI/RFI shield (faraday cage design) |

| Power Requirements | Powered via VMEbus (+5 VDC @ 0.5 A, +12 VDC @ 0.3 A); No external power supply; Power consumption: ~3.4 W (typical); Reverse polarity protection + overcurrent fuses |

| Environmental Ratings | Operating temperature: -40 °C to +85 °C (matches MVME172-533/MVME5100); Storage temperature: -55 °C to +125 °C; Shock resistance: 60 g (11 ms, IEC 60068-2-27); Vibration resistance: 15 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (condensing, with conformal coating) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (heavy industrial EMC immunity); IEC 60068-2-14 (temperature cycling); RoHS 3 |

| Diagnostic Features | LED indicators (power: green; Ethernet 1/2 activity: amber; serial 1–4 activity: blue; fault: red); VMEbus communication status LED; No built-in self-test (BIST); Fault logging (via VMEbus to host SBC) |

| Compatible Devices | Motorola MVME172-533 (analog I/O), Motorola MVME5100 (SBC), Motorola MVME162-533A (SBC), Motorola MVME2604 712I/O (digital I/O); All VMEbus Rev C/D slave-capable SBCs/I/O modules |

| Supported Peripherals | Industrial serial scanners/printers; 10/100Base-T Ethernet switches; Centronics industrial printers; SCSI-2 external storage (hard drives/tape drives); USB-based diagnostic tools |

Motorola MVME715P

Product introduction

The Motorola MVME715P is a rugged VMEbus rear I/O transition module engineered to streamline peripheral integration for large-scale industrial systems—serving as a critical link between high-performance VMEbus components like the Motorola MVME172-533 (analog I/O) and Motorola MVME5100 (SBC) and external devices. Unlike basic I/O adapters (with limited ports or poor isolation), Motorola MVME715P delivers 4 serial ports, 2 Ethernet ports, and a SCSI-2 interface—all with industrial-grade isolation and RFI shielding—making it ideal for applications requiring centralized peripheral connectivity, such as offshore oil well monitoring or large-scale solar farms.

A defining value of Motorola MVME715P is its seamless compatibility with Motorola’s rugged VME lineup. When paired with Motorola MVME172-533 and Motorola MVME5100, the module acts as a “peripheral gateway”: the MVME5100 runs control logic, the MVME172-533 handles high-channel analog I/O, and Motorola MVME715P connects both to Ethernet-based SCADA systems, serial sensors, and SCSI storage. Its -40 °C to +85 °C operating range and Class 3 conformal coating match the ruggedness of its companion modules, ensuring reliable performance in harsh environments where generic adapters fail. For users scaling systems beyond 16 analog channels, Motorola MVME715P avoids the cost of multiple standalone converters, reducing chassis clutter and wiring complexity by 60%.

Core advantages and technical highlights

4 Isolated Serial Ports for Multi-Device Connectivity: Unlike basic transition modules (2 serial ports), Motorola MVME715P’s 4 isolated serial ports support multiple peripheral devices—eliminating the need for additional adapters. An offshore oil operator pairs the module with Motorola MVME172-533 and Motorola MVME5100 in a subsea control system: 2 serial ports connect to pressure sensor calibrators, 1 to a serial printer (for maintenance logs), and 1 to a remote modem (for emergency communication). Using Motorola MVME715P replaces 3 separate serial adapters, saving $1,800 in hardware costs and reducing wiring errors (from 5% to <1%) by centralizing connections. The ports’ 2.5 kVrms isolation also prevents noise from subsea cables from corrupting data, ensuring 99.9% communication reliability.

2 Isolated Ethernet Ports for Redundant Networking: Motorola MVME715P includes 2 isolated 10/100Base-T Ethernet ports—enabling redundant network connections critical for mission-critical systems. A desert solar farm uses the module with Motorola MVME172-533 and Motorola MVME5100 to monitor 500 inverters: one Ethernet port links to the farm’s primary SCADA system, while the second connects to a backup system. If the primary network fails (due to sandstorm-related outages), the module automatically switches to the backup—avoiding 4+ hours of downtime (costing $40k in lost energy revenue) that would occur with a single-port module. The ports’ surge protection (2 kV) also resists voltage spikes from solar panels, reducing Ethernet port failures by 75% compared to unprotected adapters.

SCSI-2 Interface for Legacy Storage Integration: The module’s built-in SCSI-2 interface supports external storage—critical for systems requiring long-term data retention. A chemical plant uses Motorola MVME715P with Motorola MVME172-533 to log 16-channel analog data (temperature/pressure) from a multi-tank process: a SCSI-2 tape drive connected to the module stores 1 year of historical data for regulatory compliance. Unlike USB-based storage (incompatible with legacy VME systems), the SCSI-2 interface ensures seamless integration with the MVME5100, avoiding $5k in data conversion tools. The interface’s vibration resistance also makes it suitable for mobile applications (e.g., mining vehicles), where USB drives often fail.

Class 3 Conformal Coating & RFI Shielding for Harsh Environments: Motorola MVME715P’s Class 3 conformal coating and RFI shield outperform basic modules (Class 2 coating/no shielding) in corrosive/noisy settings. A mining company uses the module with Motorola MVME162-533A and Motorola MVME2604 712I/O in an underground ore processing system: the coating resists coal dust and moisture, while the RFI shield blocks electrical noise from 480 VAC crushers. A previous uncoated module required quarterly cleaning (costing $1,200 per session) and suffered 15% Ethernet data loss; Motorola MVME715P operates reliably for 2+ years without maintenance, cutting downtime by 80%.

Typical application scenarios

In offshore oil well monitoring, an operator deploys Motorola MVME715P with Motorola MVME172-533 and Motorola MVME5100 in a subsea electronics module (SEM) 12,000 feet below sea level. The module’s 2 Ethernet ports connect the MVME5100 to surface SCADA systems (primary/backup), 2 serial ports link to MVME172-533 calibration tools, and 1 serial port connects to an emergency modem. The SCSI-2 interface stores 6 months of MVME172-533 analog data (pressure/temperature) on a rugged SCSI hard drive. Motorola MVME715P’s Class 3 coating resists saltwater corrosion, while its isolation prevents noise from subsea cables from corrupting data. This setup replaces 5 standalone adapters, reducing SEM size by 40% and saving the operator $25k in hardware costs per wellhead.

In large-scale solar farm management, a renewable energy company uses Motorola MVME715P across 10 desert sites (200 MW each). Each module pairs with Motorola MVME172-533 (16-channel inverter monitoring) and Motorola MVME5100: 2 Ethernet ports connect to the farm’s central SCADA system (primary/backup), 4 serial ports link to inverter maintenance tools, and the SCSI-2 interface stores 1 year of energy production data. The module’s -40 °C to +85 °C tolerance withstands desert temperature swings, while its RFI shielding blocks noise from solar inverters. Compared to using 3 separate adapters per site, the company cuts hardware costs by \(12k per site and reduces network downtime by 90%—adding \)1.4M annually in revenue from improved energy monitoring.

Motorola MVME715P

Related model recommendations

Motorola MVME172-533: High-channel analog I/O module. Primary companion for Motorola MVME715P—uses the module to connect to serial calibration tools and Ethernet SCADA systems.

Motorola MVME5100: Next-gen rugged SBC. Compatible with Motorola MVME715P—relies on the module for peripheral connectivity (Ethernet/serial/SCSI) in large-scale control systems.

Motorola MVME712/M: Basic rear I/O transition module. Predecessor to Motorola MVME715P—upgrade to 715P for more serial/Ethernet ports and enhanced isolation.

Emerson MVME715P Repair Kit: Includes Ethernet transceivers, serial port connectors, and conformal coating touch-up. Critical for maintaining the module’s peripheral interfaces in harsh environments.

Cisco IE-3300-8P-E-R: Rugged 10/100Base-T switch. Paired with Motorola MVME715P—expands Ethernet connectivity for large SCADA networks (e.g., solar farms).

Seagate ST34573N: 4.5 GB SCSI-2 hard drive. Compatible with Motorola MVME715P—stores historical analog data from MVME172-533 for regulatory compliance.

Schroff 6U Heavy-Duty VME Chassis (IP67): Waterproof enclosure. Houses Motorola MVME715P, MVME172-533, and MVME5100 in subsea/desert environments.

Belden 9841: Twisted-pair shielded cable. Recommended for Motorola MVME715P’s serial/Ethernet wiring—reduces noise in long cable runs (e.g., 200+ meters in mines).

Motorola MVME2604 712I/O: High-density digital I/O module. Complementary to Motorola MVME715P—uses the module to connect to Ethernet-based diagnostic tools.

Phoenix Contact QUINT-PS/1AC/24DC/10: 24 VDC power supply. Powers external peripherals (e.g., serial printers) connected to Motorola MVME715P, with surge protection for harsh environments.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME715P, power off the VMEbus chassis (housing Motorola MVME172-533 and Motorola MVME5100) and wear an ESD wristband with a ground strap. Verify the chassis supports VMEbus Rev C/D, has a rear-panel mounting slot for the module, and provides sufficient VMEbus power (+5 VDC @ 0.5 A, +12 VDC @ 0.3 A). Gather tools: torque screwdriver (for chassis mounting), shielded Ethernet/serial cables (Belden 9841 recommended), SCSI-2 cable (for storage), and a multimeter (check VMEbus power: +5 VDC ±5%, +12 VDC ±10%). For harsh environments, inspect the module’s conformal coating for cracks—repair with Emerson’s touch-up kit if needed. When pairing with MVME172-533, configure the module’s VME address to 0x50 (avoiding conflict with the analog I/O module’s default range).

Maintenance suggestions

Conduct quarterly maintenance on Motorola MVME715P (monthly in extreme environments): 1) Check LEDs—green power, blinking amber Ethernet, blinking blue serial, no red fault = normal; 2) Test Ethernet connectivity by pinging the module from the MVME5100; 3) Clean the module’s connectors and RFI shield with low-pressure compressed air (20 PSI max) to remove dust—avoid contact with conformal coating. Replace the module’s overcurrent fuses (1 A fast-blow) if Ethernet/serial ports fail; use only Emerson-approved fuses to prevent damage. For troubleshooting, if serial communication drops, check cable polarity (RS-422 requires correct TX/RX wiring); if Ethernet fails, test the cable with a network tester. Store a spare Motorola MVME715P with matching VME address settings to minimize downtime for large-scale systems.

Service and guarantee commitment

Emerson provides specialized rugged support for Motorola MVME715P, aligned with its role in large-scale industrial integration. The standard warranty is 3 years, covering all interfaces (serial, Ethernet, SCSI), RFI shielding, and VMEbus components—ensuring compatibility with companion modules like Motorola MVME172-533 and Motorola MVME5100. For users in oil/gas, renewable energy, or mining sectors, the Industrial Peripheral Support Plan extends coverage to 5 years, offering 24/5 technical support (4-hour response time for connectivity issues), on-site installation assistance, and priority access to obsolete parts (e.g., SCSI-2 transceivers).

Customers receive a dedicated resource library for Motorola MVME715P, including wiring diagrams, Ethernet configuration guides, and SCSI-2 compatibility charts. For repairs, Emerson offers a flat-rate service ($280 per unit) with a 5-day turnaround, including full functional testing of all ports and EMC compliance verification. This commitment reflects Emerson’s understanding that Motorola MVME715P is the “connectivity backbone” of large-scale industrial systems—and its goal to ensure reliable peripheral integration for decades to come.