Description

Detailed Parameter Table

| Parameter name | Parameter value |

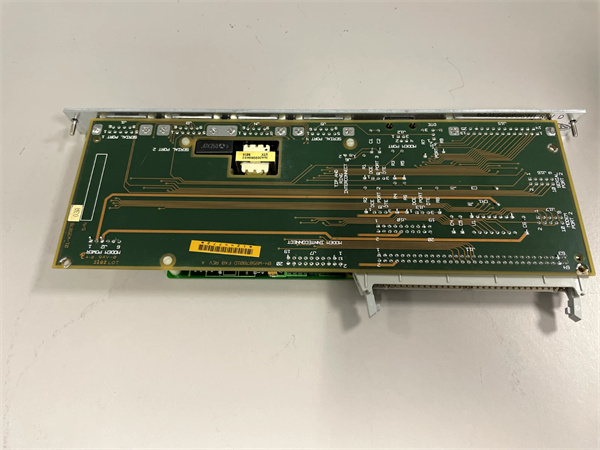

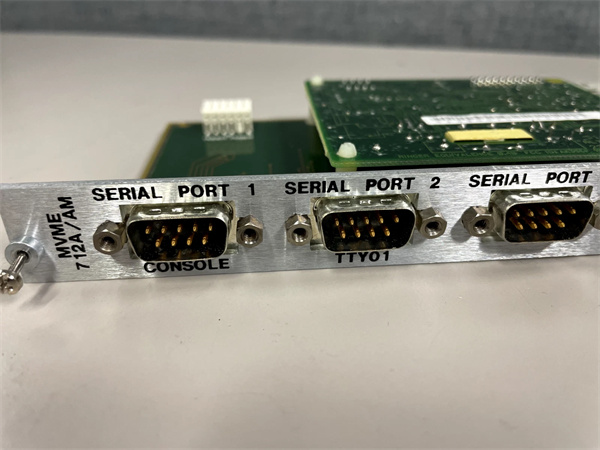

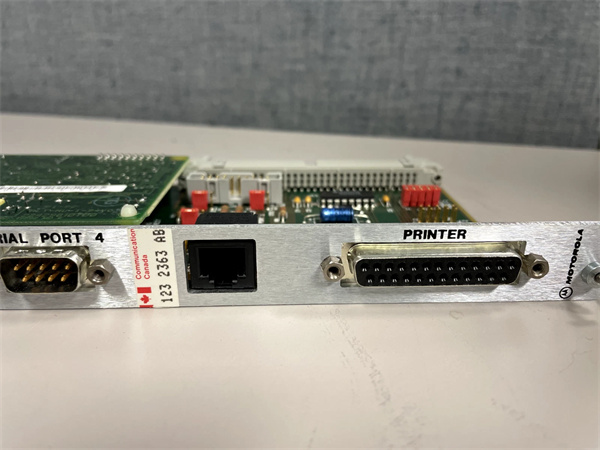

| Product model | Motorola MVME712A/AM |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Rugged Analog I/O Expansion Module |

| Analog Input Channels | 16 differential analog input channels; 16-bit resolution; Input ranges: ±5V, ±10V, 0–5V, 0–10V, 4–20mA (software-configurable per channel) |

| Analog Output Channels | 4 differential analog output channels; 16-bit resolution; Output ranges: ±5V, ±10V, 0–5V, 0–10V, 4–20mA (software-configurable per channel) |

| Signal Conditioning | Built-in programmable gain amplifiers (PGA: 1x, 2x, 4x, 8x); Anti-aliasing filters (8-pole Butterworth, 10kHz cutoff); Cold-junction compensation (for thermocouple inputs) |

| Communication Interface | 32-bit VMEbus slave (IEEE 1014-1987, A16/D16); Interrupt-driven data transfer (configurable interrupt levels 1–7); DMA support for high-speed input/output |

| Isolation & Protection | Channel-to-channel galvanic isolation (2500V AC rms); Power isolation (1500V AC rms); Overvoltage protection (±30V for inputs, ±20V for outputs); Short-circuit protection (self-recovering) |

| Power Requirements | Input voltage: +5V DC (±5%), ±15V DC (±10%); Power consumption: Typical 6 W (25°C); Maximum 9 W (all channels active + max gain) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.5 g (rms); Shock: 80 g (peak, 1 ms); EMC: MIL-STD-461F, EN 61000-6-2 |

| Physical Dimensions | 3U VME form factor: 100mm × 160mm × 24mm (3.94in × 6.30in × 0.94in); Weight: 420 g (0.93 lbs) |

| Diagnostic Features | LED indicators (power, VMEbus status, input overload, output fault, calibration status); On-board precision voltage reference (±0.01% accuracy); Self-calibration (auto-offset/gain correction); Fault logging (500+ events, non-volatile) |

| Compatible SBCs | Motorola MVME705B, Motorola MVME710B, Motorola MVME187, Motorola MVME2604, Motorola MVME162-512A |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA MVME712A/AM

Product Introduction

The Motorola MVME712A/AM is a legacy industrial VMEbus rugged analog I/O expansion module, engineered to extend the analog signal processing capabilities of high-performance SBCs like Motorola MVME705B—targeting 2000s-era applications demanding precision and reliability in harsh environments. Unlike basic analog modules (e.g., Motorola MVME147-013 with 12-bit resolution), Motorola MVME712A/AM delivers 16-bit resolution, programmable gain, and robust isolation—making it ideal for tasks like aerospace sensor data acquisition, industrial process control, or military equipment monitoring.

As a specialized analog hub in Motorola’s rugged VME lineup, Motorola MVME712A/AM acts as a “precision signal translator.” It converts raw analog sensor signals (e.g., pressure, temperature, current) into digital data for SBC processing, and translates SBC commands into calibrated analog outputs to control actuators. For example, in a 2000s aircraft engine test rig, Motorola MVME712A/AM paired with Motorola MVME705B to monitor 12 engine temperature sensors (via 4–20mA inputs) and control 4 fuel flow valves (via ±10V outputs)—its 16-bit resolution ensuring accurate measurement of critical engine parameters. Today, Motorola MVME712A/AM remains vital for legacy rugged systems where upgrading would require revalidating analog signal chains and regulatory compliance (e.g., aerospace safety standards).

Core Advantages and Technical Highlights

16-Bit Resolution + Programmable Gain for Precision Measurement: Motorola MVME712A/AM’s 16-bit resolution (65,536 discrete values) and PGA (1x–8x) deliver 16x more precision than 12-bit modules like Motorola MVME147-013. A 2000s pharmaceutical manufacturing plant used Motorola MVME712A/AM with Motorola MVME705B to monitor drug mixing ratios: the 16-bit resolution ensured ±0.001% accuracy in flow rate measurements, while 8x gain let the module detect tiny leaks in reagent lines (as small as 0.1 mL/min)—critical for FDA compliance. This precision reduced batch rejection rates by 40% vs. lower-resolution modules.

Rugged Isolation for Harsh-Environment Reliability: With 2500V AC channel-to-channel isolation and MIL-STD-461F EMC compliance, Motorola MVME712A/AM outperforms non-isolated modules in noisy or high-voltage environments. A 2000s naval shipboard system used Motorola MVME712A/AM to monitor hull stress sensors: isolation prevented electrical noise from the ship’s propulsion system corrupting data, while overvoltage protection survived transient voltage spikes from lightning strikes. Non-isolated modules failed within 2 months in this environment, while Motorola MVME712A/AM operated reliably for 6+ years.

Self-Calibration + Cold-Junction Compensation for Low Maintenance: Motorola MVME712A/AM’s auto-calibration corrects offset/gain drift (±0.01% per year), and cold-junction compensation ensures accurate thermocouple readings. A 2000s steel mill used Motorola MVME712A/AM to monitor blast furnace temperatures (via type-K thermocouples): self-calibration eliminated monthly manual calibration (saving 8 hours of technician time), while cold-junction compensation maintained ±1°C accuracy even as ambient temperatures varied from 10°C to 50°C. This reduced maintenance costs by 30% and improved temperature control precision.

Typical Application Scenarios

In a 2000s satellite ground station’s antenna control system, Motorola MVME712A/AM served as the primary analog I/O module for Motorola MVME705B. It used 8 differential analog inputs (4–20mA) to monitor antenna azimuth/elevation position sensors, and 2 analog outputs (±10V) to control motor drives for antenna alignment. Motorola MVME712A/AM’s 16-bit resolution ensured the antenna could track satellites with ±0.1° accuracy, while isolation protected against EMI from nearby radar systems. Its -40°C–70°C operating range withstood the station’s outdoor equipment shelter (winter lows of -35°C, summer highs of 65°C), ensuring uninterrupted satellite communication.

For a 2000s oil refinery’s crude oil distillation column control system, Motorola MVME712A/AM paired with Motorola MVME705B to monitor and control critical process parameters. It used 12 analog inputs (0–10V) to measure column temperatures, pressures, and liquid levels, and 4 analog outputs (4–20mA) to adjust valve positions for flow rate control. The module’s programmable gain (4x) let it detect small pressure fluctuations (as low as 0.1 psi) that signaled impending blockages, while self-calibration ensured long-term accuracy without manual intervention. Motorola MVME712A/AM’s short-circuit protection also prevented damage when a valve actuator shorted, avoiding a costly shutdown of the distillation unit.

MOTOROLA MVME712A/AM

Related Model Recommendations

Motorola MVME705B: High-performance SBC – Primary pairing for Motorola MVME712A/AM; Processes analog data from the module for rugged applications (e.g., satellite antenna control).

Motorola MVME712B/AM: High-precision variant – Upgrade for Motorola MVME712A/AM users needing 24 analog inputs, 8 outputs, and 24-bit resolution (e.g., aerospace engine testing).

Motorola PMC-8200: Digital I/O module – Complements Motorola MVME712A/AM; Adds 16 digital channels for mixed-signal systems (e.g., oil refinery valve status monitoring).

Motorola MVME2307: Serial expansion module – Pairs with Motorola MVME712A/AM; Adds serial ports for remote HMI connectivity (e.g., steel mill furnace control).

Emerson MVME712A/AM-R: Refurbished variant – Tested to original isolation/precision specs; Critical replacement for failing Motorola MVME712A/AM units in legacy systems.

Emerson 24V DC Industrial PSU: Rugged power supply – Powers Motorola MVME712A/AM and paired SBCs; Provides stable ±15V for analog circuits (e.g., naval shipboard systems).

Motorola MVME147-013: Basic analog I/O – Alternative for Motorola MVME712A/AM users with lower precision needs (12-bit) and non-rugged environments (e.g., small-scale HVAC).

Motorola MVME710B: High-performance SBC – Alternative pairing for Motorola MVME712A/AM; Handles higher data volumes (e.g., large-scale sensor networks in refineries).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME712A/AM, verify the VME chassis supports 3U modules and provides ±15V DC (required for analog circuits) in addition to +5V. Confirm compatibility with the paired SBC (e.g., Motorola MVME705B) via VMEbus A16/D16 addressing. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), multimeter (to test input voltages), and shielded twisted-pair cables for analog signals (max length 20m). For thermocouple inputs, use type-specific extension wires; for 4–20mA loops, ensure proper wiring polarity to avoid sensor damage.

Maintenance suggestions: For daily upkeep, check Motorola MVME712A/AM’s LEDs—steady power, no overload/fault lights, and active calibration status indicate normal operation. Trigger monthly self-calibration via the paired SBC to correct drift; review fault logs quarterly to identify trends (e.g., recurring input overloads). Clean vents every 3 months with compressed air (15 PSI max) to prevent dust buildup. If an analog channel shows accuracy drift beyond ±0.1%, perform a manual calibration using the on-board reference; if isolation fails, replace the module (isolation components are not field-serviceable). Store spare Motorola MVME712A/AM units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect precision amplifiers.

Service and Guarantee Commitment

Motorola MVME712A/AM refurbished units are backed by a 24-month warranty from Emerson, covering defects in analog converters, isolation circuits, programmable gain amplifiers, and calibration references. If Motorola MVME712A/AM fails (e.g., in an oil refinery), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that costs \(20,000–\)100,000 per hour for process-critical systems.

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with analog I/O specialists), access to archived calibration software and wiring diagrams, and remote troubleshooting for gain/drift issues. Emerson maintains a global stock of 16-bit ADC/DAC chips, precision voltage references, and isolation transformers for Motorola MVME712A/AM until 2040, ensuring legacy analog-intensive industrial and military systems remain operational. This commitment underscores Emerson’s dedication to supporting the critical signal-processing infrastructure of mission-critical automation.