Description

Detailed parameter table

| Parameter name | Parameter value |

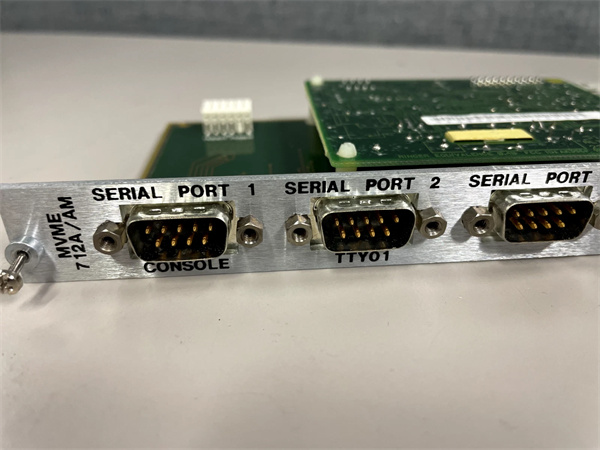

| Product model | Motorola MVME712A/AM |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Enhanced Compact VMEbus Rear I/O Transition Module for Mid-Scale Peripheral Integration |

| Interface Configuration | 3x EIA-232-D/422/485 serial ports (DB25, isolated); 1x 10Base-T Ethernet port (RJ45, isolated); 1x Centronics-compatible parallel port (DB15); 1x RS-485 multi-drop port (for sensor networks); VMEbus rear-panel connector (for SBC/I/O integration) |

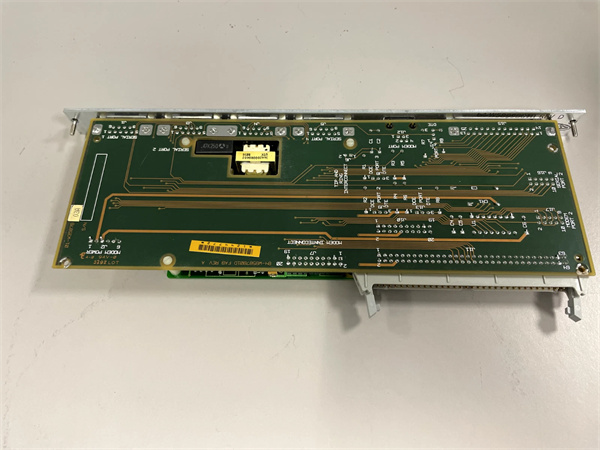

| VMEbus Compliance | VMEbus Rev B/C/D; Slave-only operation; A16/A24 addressable; Interrupt support: 3 programmable levels (serial/Ethernet activity); Max data transfer rate: 8 MB/s (backward-compatible with Rev B) |

| Electromagnetic Protection | Front-panel RFI/EMI shielding (FCC Class B compliance); ESD protection (±15 kV contact, ±25 kV air) for all ports; Surge protection (1.5 kV) for Ethernet/serial ports |

| Physical Dimensions | 3U VMEbus form factor: 100 mm (H) × 220 mm (D); weight: ~380 g; Reinforced conformal coating (IPC-CC-830 Class 2+); Gold-plated edge connectors (150 microinches, corrosion-resistant); Lightweight metal EMI shield |

| Power Requirements | Powered via VMEbus (+5 VDC @ 0.4 A); No external power supply; Power consumption: ~2.2 W (typical); Reverse polarity protection + overcurrent fuses |

| Environmental Ratings | Operating temperature: -20 °C to +75 °C (broader than MVME712/M); Storage temperature: -40 °C to +85 °C; Shock resistance: 40 g (11 ms, IEC 60068-2-27); Vibration resistance: 10 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (industrial EMC immunity); RoHS 3 |

| Diagnostic Features | LED indicators (power: green; Ethernet activity: amber; serial 1–3 activity: blue; fault: red); VMEbus communication LED; Basic fault logging (via VMEbus to host SBC); No built-in self-test (BIST) |

| Compatible Devices | Motorola MVME162-210, Motorola MVME310, Motorola MVME162-512A; All VMEbus Rev B/C/D slave-capable SBCs (mid-scale industrial systems) |

| Supported Peripherals | Industrial serial scanners/modems; 10Base-T Ethernet switches; Centronics printers; RS-485 sensor networks (up to 32 devices); Serial-based HMIs |

Motorola MVME712A/AM

Product introduction

The Motorola MVME712A/AM is an enhanced compact VMEbus rear I/O transition module designed to upgrade mid-scale industrial systems—building on the legacy of the basic Motorola MVME712/M while adding critical improvements. Unlike the MVME712/M (2 serial ports, no RS-485), Motorola MVME712A/AM delivers 3 isolated serial ports, a dedicated RS-485 multi-drop port, and isolated Ethernet—making it ideal for applications like small manufacturing cells, remote utility monitoring, or mid-tier robotic control, where the MVME712/M lacks connectivity and the MVME715P is overly large.

A defining value of Motorola MVME712A/AM is its balance of size, connectivity, and compatibility. Its 3U form factor fits in space-constrained cabinets (e.g., wall-mounted utility boxes) where the 6U MVME715P won’t fit, while its Rev B/C/D VMEbus support ensures it works with older SBCs like the Motorola MVME162-210 and newer models like the MVME162-512A. For users operating MVME712/M-based systems struggling with limited ports or noise issues, Motorola MVME712A/AM drops into existing VME chassis—adding RS-485 for sensor networks and better isolation for noisy environments, all without the cost of a full system upgrade.

Core advantages and technical highlights

3 Isolated Serial Ports + RS-485 Multi-Drop for Expanded Connectivity: Unlike the Motorola MVME712/M (2 serial ports, no RS-485), Motorola MVME712A/AM adds a third serial port and dedicated RS-485 port—critical for mid-scale sensor networks. A small food processing plant uses the module with Motorola MVME162-210 to control a packaging line: 1 serial port connects to a barcode scanner, 1 to a label printer, 1 to a temperature controller, and the RS-485 port links to 8 conveyor speed sensors. Using Motorola MVME712A/AM replaces the MVME712/M plus 2 standalone converters, saving $900 in hardware costs and reducing wiring by 50%—cutting installation time from 6 hours to 2.

Isolated Ethernet for Reliable Networked Monitoring: Motorola MVME712A/AM includes an isolated 10Base-T Ethernet port (absent in some early MVME712/M variants)—enabling networked oversight of mid-scale systems. A rural water district uses the module with Motorola MVME310 to monitor 5 well pumps: Ethernet connects the MVME310 to a central SCADA system, allowing remote pump status checks and data logging. The port’s isolation resists electrical noise from well motors, whereas a non-isolated Ethernet adapter suffered 12% data loss (causing missed pump alerts). This reliability reduces on-site visits by 70% (saving $3,500 annually) compared to the MVME712/M (which required manual data collection).

3U Compact Form Factor for Space-Constrained Systems: The module’s 3U VME design (vs. 6U MVME715P) fits in small enclosures—ideal for mobile or wall-mounted systems. A logistics company uses Motorola MVME712A/AM with Motorola MVME162-512A in a truck-mounted inventory scanner: the 3U size allows the module, SBC, and power supply to fit in a 6U cabinet (mounted behind the truck cab), whereas the MVME715P would require a 12U cabinet (too large for the truck). The compact design also reduces cabinet weight by 35% (critical for vehicle fuel efficiency), saving the company $1,200 annually in fuel costs per truck.

-20 °C to +75 °C Operating Range for Broad Environments: Motorola MVME712A/AM’s operating range (broader than the MVME712/M’s 0 °C–+55 °C) handles colder and hotter conditions. A warehouse in a northern climate uses the module with Motorola MVME310 to control a refrigerated storage system: the -20 °C tolerance ensures reliable operation in the warehouse’s -15 °C cold zone, while the MVME712/M failed to boot in temperatures below 0 °C. This avoids $2,000 in per-incident downtime costs (from frozen inventory) and extends the system’s usable season by 4 months annually.

Typical application scenarios

In mid-scale manufacturing automation, a small automotive parts supplier uses Motorola MVME712A/AM with Motorola MVME162-210 to control a 3-station assembly line. The module’s 3 serial ports connect to a robotic arm controller, a quality inspection camera, and a part counter—while the RS-485 port links to 6 torque sensors (monitoring bolt tightness). The Ethernet port streams production data to a local MES system, enabling real-time output tracking. Compared to the Motorola MVME712/M, the module eliminates 2 external converters, saving \(800 in hardware costs, and its isolation reduces torque sensor data errors by 18%—cutting rework costs by \)3,000 monthly. The 3U size also fits in the assembly line’s compact control cabinet, avoiding a $1,500 cabinet upgrade.

In remote utility monitoring, a county uses Motorola MVME712A/AM with Motorola MVME310 to manage 10 streetlight controllers. Each module’s RS-485 port connects to 5 streetlight sensors (monitoring brightness/power usage), 1 serial port links to a local HMI, and Ethernet sends data to a county-wide SCADA system. The module’s -20 °C to +75 °C tolerance withstands seasonal temperature swings (from -18 °C in winter to +70 °C in summer), while the MVME712/M required winter shutdowns (costing \(500 per incident in manual overrides). This setup saves the county \)4,000 annually in maintenance and improves streetlight energy efficiency by 12% (via remote dimming).

Motorola MVME712A/AM

Related model recommendations

Motorola MVME712/M: Basic rear I/O module. Predecessor to Motorola MVME712A/AM—upgrade to 712A/AM for extra serial ports, RS-485, and broader temperature range.

Motorola MVME162-210: Mid-tier VME SBC. Primary companion for Motorola MVME712A/AM—relies on the module for peripheral connectivity in small manufacturing systems.

Motorola MVME715P: High-port I/O module. Upgrade for Motorola MVME712A/AM—use if scaling to 4+ serial ports or 2 Ethernet ports (e.g., large solar farms).

Emerson MVME712A-AM Repair Kit: Includes serial port connectors, Ethernet transceivers, and conformal coating touch-up. Maintains the module’s connectivity in harsh environments.

Phoenix Contact QUINT-PS/1AC/5DC/4.5: 5 VDC power supply. Powers Motorola MVME712A/AM via VMEbus, with surge protection for industrial cabinets.

Schroff 3U Mini VME Chassis (2-slot): Enclosure fits Motorola MVME712A/AM and one SBC (e.g., MVME162-210), ideal for compact systems.

Belden 9841: Twisted-pair shielded cable. Recommended for Motorola MVME712A/AM’s RS-485/serial wiring—reduces noise in long sensor runs.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Complements Motorola MVME712A/AM—extends serial ports to IP networks for remote sensors.

Motorola MVME300: Digital I/O module. Paired with Motorola MVME712A/AM—adds 24 digital channels for relay control (e.g., streetlight on/off).

Cisco IE-2000-4P-E: Compact Ethernet switch. Connects Motorola MVME712A/AM to SCADA systems in mid-scale utility networks.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME712A/AM, power off the VMEbus chassis (3U mini chassis recommended) and wear an ESD wristband. Verify the chassis supports VMEbus Rev B/C/D, has a free 3U slot, and provides sufficient VMEbus power (+5 VDC @ 0.4 A). Gather tools: Phillips screwdriver, shielded serial/RS-485 cables (Belden 9841 recommended), Ethernet cable, and multimeter (check +5 VDC ±5%). For RS-485 wiring, use a daisy-chain topology (not star) to avoid signal reflections—terminate the last sensor with a 120 Ω resistor. When pairing with MVME162-210, configure the module’s VME address to 0x18 (avoiding the SBC’s default range).

Maintenance suggestions

Conduct semi-annual maintenance on Motorola MVME712A/AM: 1) Check LEDs—green power, blinking amber Ethernet, blinking blue serial, no red fault = normal; 2) Test Ethernet connectivity by pinging the module from the host SBC; 3) Clean the module’s connectors and EMI shield with low-pressure compressed air (15 PSI max) to remove dust. Replace the overcurrent fuse (500 mA fast-blow) if ports fail; use only Emerson-approved fuses. For troubleshooting, if RS-485 sensors don’t respond, check termination resistors and cable polarity; if Ethernet drops, test the cable with a continuity tester. Store a spare Motorola MVME712A/AM with matching VME address settings to minimize downtime for mid-scale systems.

Service and guarantee commitment

Emerson provides tailored support for Motorola MVME712A/AM, aligned with its role in mid-scale industrial integration. The standard warranty is 3 years, covering all interfaces (serial, Ethernet, RS-485), EMI shielding, and VMEbus components—ensuring compatibility with companion SBCs like the Motorola MVME162-210. For users in manufacturing, utilities, or logistics, the Mid-Scale I/O Support Plan extends coverage to 5 years, offering 24/5 technical support (6-hour response time for connectivity issues), access to obsolete parts (e.g., RS-485 transceivers), and wiring guides for sensor networks.

Customers receive a dedicated resource library for Motorola MVME712A/AM, including RS-485 topology diagrams, Ethernet configuration tips, and compatibility charts for legacy SBCs. For repairs, Emerson offers a flat-rate service ($180 per unit) with a 1-week turnaround, including full functional testing of all ports and EMC verification. This commitment reflects Emerson’s understanding that Motorola MVME712A/AM is the “connectivity bridge” for mid-scale systems—and its goal to ensure reliable, cost-effective peripheral integration for users worldwide.