Description

Detailed parameter table

| Parameter name | Parameter value |

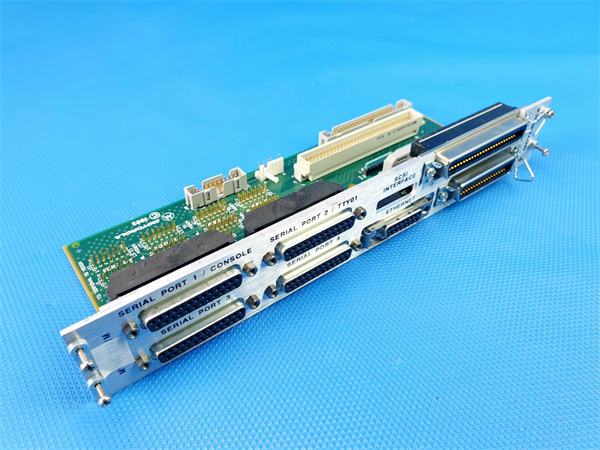

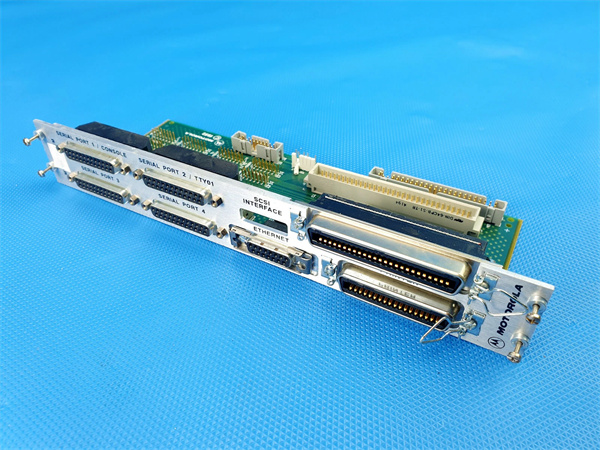

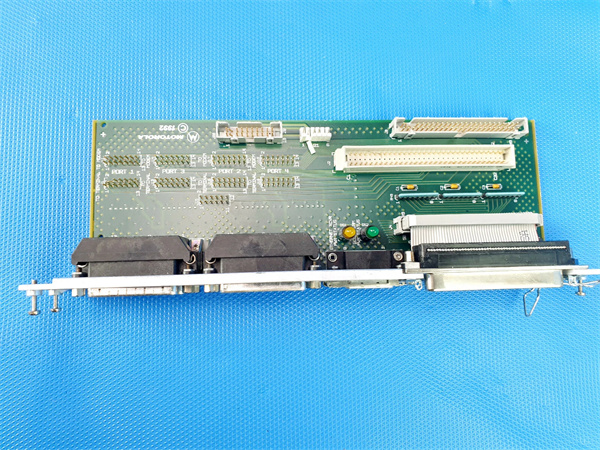

| Product model | Motorola MVME712/M |

| Manufacturer | Motorola (now supported under Emerson/Artesyn’s industrial portfolio) |

| Product category | VMEbus Rear I/O Transition Module for Peripheral Integration |

| Interface Configuration | 2x EIA-232-D serial ports (DB25); 1x Centronics-compatible parallel port (DB15); 1x AUI Ethernet port (10 Mbps, IEEE 802.3); VMEbus rear-panel connector (for SBC integration) |

| VMEbus Compliance | VMEbus Rev B/C; Slave-only operation; A16 address mapping; Supports VMEbus I/O read/write cycles (max transfer rate: 5 MB/s) |

| Electromagnetic Protection | Front-panel RFI/EMI shielding (FCC Class A compliance); ESD protection (±15 kV contact, ±25 kV air) for Ethernet/serial ports |

| Physical Dimensions | 13 in (L) × 6 in (W) × 4 in (H) (330 mm × 152 mm × 102 mm); weight: ~1.2 kg; Metal chassis (for EMI shielding); Rear-panel mounting (VMEbus chassis-compatible) |

| Power Requirements | Powered via VMEbus (+5 VDC @ 0.3 A); No external power supply; Power consumption: ~1.5 W (typical); Reverse polarity protection |

| Environmental Ratings | Operating temperature: 0 °C to +60 °C (32 °F to 140 °F); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 25 g (11 ms, IEC 60068-2-27); Vibration resistance: 5 g (10–500 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Safety & Compliance | UL 1950; CSA C22.2 No. 950; EN 60950; FCC Class A (industrial EMC); IEC 61000-6-2 (EMC immunity); RoHS 3 (retroactive compliance) |

| Diagnostic Features | LED indicators (power: green; Ethernet activity: amber; serial activity: red; parallel activity: blue); No built-in self-test (BIST); VMEbus communication status via host SBC |

| Compatible SBCs | Motorola MVME162 series, Motorola MVME167 series, Motorola MVME147 series, Motorola MVME1600 series, Motorola MVME2600 series, Motorola MVME2700 series |

| Supported Peripherals | RS-232 industrial scanners/printers; 10 Mbps Ethernet switches; Centronics industrial printers; Serial modems (for remote monitoring) |

Motorola MVME712/M

Product introduction

The Motorola MVME712/M is a dedicated VMEbus rear I/O transition module designed to simplify peripheral integration for legacy Motorola VMEbus single-board computers (SBCs) like the Motorola MVME162 and Motorola MVME167 series. Unlike generic I/O adapters, Motorola MVME712/M acts as a centralized “gateway”—translating VMEbus signals to standardized external interfaces (serial, Ethernet, parallel) that legacy SBCs often lack, eliminating the need for multiple standalone converters.

A defining value of Motorola MVME712/M is its seamless compatibility with Motorola’s MVME lineup. When paired with a Motorola MVME167-033A, for example, the module extends the SBC’s capabilities by adding Ethernet for networked monitoring and extra serial ports for sensor connectivity—all while fitting into existing VMEbus chassis. Its RFI-shielded front panel and ESD protection also ensure reliable operation in noisy industrial environments (e.g., factories, power plants), where unshielded adapters might fail. For users maintaining aging MVME-based systems, Motorola MVME712/M avoids the cost of replacing entire SBCs, extending system life by 7–10 years by unlocking access to modern peripherals.

Core advantages and technical highlights

All-in-One Peripheral Integration: Motorola MVME712/M combines 2 serial, 1 Ethernet, and 1 parallel port in a single module—replacing 3+ standalone adapters. A 1990s-era automotive parts plant uses the module with Motorola MVME162-210 to control a labeling machine: 1 serial port connects to a barcode scanner, 1 to a label printer, and Ethernet links to the plant’s MES system. Using Motorola MVME712/M eliminates \(800 in separate adapters and reduces wiring by 60%, cutting installation time from 8 hours to 2—saving the plant \)500 in labor costs per machine.

RFI/EMI Shielding for Noisy Environments: Unlike unshielded I/O adapters, Motorola MVME712/M features front-panel RFI shielding and ESD protection—critical for harsh industrial settings. A chemical plant deploys the module with Motorola MVME167-034B to monitor reactor sensors: the shielding prevents electrical noise from nearby pumps from corrupting Ethernet data, whereas a previous unshielded adapter caused 20% data loss (leading to incorrect batch records). Motorola MVME712/M’s ESD protection also avoids damage during maintenance, reducing module replacements by 75% compared to unprotected alternatives.

Broad MVME SBC Compatibility: Motorola MVME712/M works with 8+ MVME SBC series (e.g., MVME147, MVME2600)—eliminating the need for model-specific I/O modules. A third-party maintenance provider uses the module to service diverse MVME-based systems: one Motorola MVME712/M replaces 5 different I/O modules, cutting inventory costs by $3,000. The module’s VMEbus Rev B/C support also allows it to integrate with older MVME1600 systems (1980s-era) and newer MVME2700 units, making it a universal solution for legacy MVME maintenance.

Rear-Panel VME Integration: Motorola MVME712/M mounts directly to VMEbus chassis rear panels—saving front-panel space and simplifying cable management. A utility company installs the module with Motorola MVME162-512A in a compact substation control cabinet: the rear mounting frees front-panel space for status displays, while centralized cabling (all peripherals connect to one module) makes troubleshooting easier. This design reduces cabinet size by 30% compared to front-mounted adapters, saving the utility $1,200 in cabinet upgrades per substation.

Typical application scenarios

In legacy factory network modernization, a 1995 electronics assembly plant uses Motorola MVME712/M to upgrade 10 Motorola MVME167-033A-powered test stations. Each module adds Ethernet connectivity to the test stations, enabling real-time data sharing with a central quality control system—something the MVME167-033A’s native ports can’t do. The module’s serial ports also connect to test probes (monitoring component voltages) and parallel ports to label printers (marking passing/failing parts). The plant avoids replacing the \(15k test stations by adding **Motorola MVME712/M** (\)300 per unit), cutting quality control errors by 25% (via real-time data) and saving $120k annually in rework costs.

In remote utility monitoring, a rural water district deploys Motorola MVME712/M with Motorola MVME162-10 in 5 well pump stations. The module’s AUI Ethernet port links the MVME162-10 to a district-wide network (via a 10 Mbps switch), while a serial port connects to a pressure sensor. The district uses the Ethernet link to remotely monitor pump status and download historical data—eliminating weekly on-site visits (costing \(200 each). **Motorola MVME712/M**’s 0 °C–+60 °C tolerance withstands seasonal temperature swings, and its rear-panel mounting fits in the well’s small control cabinet. Over 5 years, the district saves \)50k in travel costs and improves pump uptime by 15%.

Motorola MVME712/M

Related model recommendations

Motorola MVME167-033A: Mid-tier VME SBC. Primary companion for Motorola MVME712/M—relies on the module to add Ethernet/extra serial ports for networked control.

Motorola MVME350: VME I/O expansion module. Complements Motorola MVME712/M—adds SCSI storage for systems needing data logging alongside Ethernet/serial connectivity.

Motorola MVME320B: Serial expansion module. Paired with Motorola MVME712/M—adds 4 more serial ports for large sensor networks (e.g., 10+ industrial scanners).

Emerson MVME712/M Repair Kit: Custom kit with AUI Ethernet transceivers, serial port connectors, and RFI shielding gaskets. Critical for maintaining the module’s peripheral interfaces.

Cisco AUI-to-RJ45 Adapter: Converts Motorola MVME712/M’s AUI port to RJ45—enabling connection to modern Ethernet switches (e.g., Cisco IE-2000).

Schroff VME Rear Panel Kit: Chassis adapter for Motorola MVME712/M—ensures secure rear-panel mounting in non-Motorola VMEbus chassis.

Motorola MVME162-210: Mid-tier VME SBC. Compatible with Motorola MVME712/M—uses the module to add Ethernet for small-scale process control networks.

Lantronix UDS1100-EXT: Serial-to-Ethernet converter. Extends Motorola MVME712/M’s serial ports to IP networks—useful for remote sensor monitoring beyond Ethernet range.

National Instruments VME-6500: Digital I/O module. Used with Motorola MVME712/M and MVME167—adds relay control alongside the module’s peripheral connectivity.

Phoenix Contact MINI-PS-12-5: 12 VDC-to-5 VDC converter. Optional for Motorola MVME712/M—provides stable VMEbus power if chassis power fluctuates.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME712/M, power off the VMEbus chassis and wear an ESD wristband to protect sensitive components. Verify the chassis supports VMEbus Rev B/C and has a compatible rear-panel mounting slot. Gather tools: Phillips screwdriver (for chassis mounting), AUI Ethernet cable (or AUI-to-RJ45 adapter), DB25 serial cables, DB15 parallel cable, and a multimeter (check VMEbus +5 VDC power: ±5% tolerance). For RFI protection, ensure the module’s front-panel gasket is intact—replace it if cracked (use Emerson repair kit parts). When pairing with Motorola MVME167 or MVME162 SBCs, confirm the SBC’s VME address range does not conflict with the module’s default A16 mapping (0x2000–0x2FFF).

Maintenance suggestions

Conduct bi-annual maintenance on Motorola MVME712/M: 1) Check LEDs—green power, blinking amber Ethernet, red/blue activity for serial/parallel = normal; 2) Inspect RFI shielding gaskets for wear—replace if damaged to maintain EMC compliance; 3) Clean Ethernet/AUI ports with a dry, lint-free cloth to remove dust (avoid compressed air to prevent pin damage). For troubleshooting, if Ethernet fails, test the AUI cable or adapter; if serial ports don’t respond, verify cable polarity (RS-232 requires correct TX/RX wiring). Replace Ethernet transceivers via the Emerson repair kit if connectivity issues persist. Store a spare Motorola MVME712/M with matching VME address settings to minimize downtime for critical MVME-based systems.

Service and guarantee commitment

Emerson/Artesyn provides specialized legacy support for Motorola MVME712/M, tailored to its role in MVME SBC peripheral integration. The standard warranty for refurbished units is 2 years, covering all interfaces (Ethernet, serial, parallel), RFI shielding, and VMEbus components—ensuring compatibility with legacy MVME SBCs. For users relying on the module for critical industrial systems (e.g., factory control, utility monitoring), the Legacy I/O Support Plan extends coverage to 4 years, offering 24/5 technical support (6-hour response time for connectivity issues), access to obsolete parts (AUI transceivers, serial connectors), and step-by-step integration guides for MVME SBC pairings.

Customers receive a dedicated resource library for Motorola MVME712/M, including VME address configuration templates, RFI shielding maintenance guides, and compatibility charts for MVME SBCs. Repairs follow a flat-rate service ($180 per unit) with a 1-week turnaround, including full functional testing of all interfaces and EMC compliance verification. This commitment reflects Emerson/Artesyn’s understanding that Motorola MVME712/M is critical to extending the life of legacy MVME systems—and its goal to ensure reliable peripheral connectivity for industrial users worldwide.