Description

Detailed parameter table

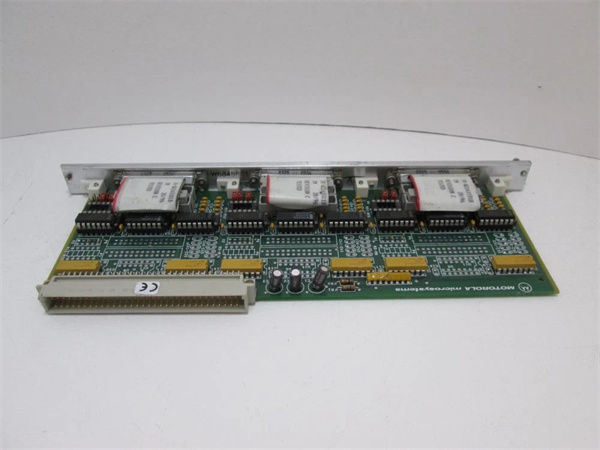

| Parameter name | Parameter value |

| Product model | Motorola MVME705B |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged VMEbus System Controller Module for Chassis Resource Management |

| VMEbus Core Functions | Bus arbitration (supports 16 master devices); Interrupt handling (8 priority levels); System clock distribution (16 MHz/33 MHz selectable); VMEbus reset control (local/remote); JTAG boundary scan support |

| Interface Configuration | 1x VMEbus backplane interface (Rev B/C/D); 1x front-panel debug port (RS-232); 1x system status port (for chassis monitoring); 4x LED indicator ports (for external status panels) |

| Bus Performance | Max arbitration latency: 200 ns; Interrupt response time: <100 ns; Clock jitter: <5 ns; Supports A16/A24/A32 address spaces; D8/D16/D32/D64 data widths |

| Physical Dimensions | 3U VMEbus form factor: 100 mm (H) × 180 mm (D); weight: ~320 g; Reinforced conformal coating (IPC-CC-830 Class 2); Gold-plated edge connectors (150 microinches, corrosion-resistant); Metal EMI shield |

| Power Requirements | Powered via VMEbus (+5 VDC @ 0.3 A, +12 VDC @ 0.2 A); Power consumption: ~1.9 W (typical); Reverse polarity protection + overcurrent fuses (1 A fast-blow) |

| Environmental Ratings | Operating temperature: -20 °C to +75 °C (matches MVME712A/AM); Storage temperature: -40 °C to +85 °C; Shock resistance: 40 g (11 ms, IEC 60068-2-27); Vibration resistance: 10 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (industrial EMC immunity); RoHS 3 |

| Diagnostic Features | LED indicators (power: green; bus activity: amber; arbitration fault: red; clock status: blue); Built-in self-test (BIST) for arbitration logic; Fault logging (via debug port); Remote status monitoring (via system status port) |

| Compatible Devices | Motorola MVME712A/AM (I/O transition), Motorola MVME162-210 (SBC), Motorola MVME172-263/260 (analog I/O), Motorola MVME2604 712I/O (digital I/O); All VMEbus Rev B/C/D master/slave modules |

| Target Applications | Mid-to-large-scale VMEbus chassis (5+ modules); Industrial control systems with multiple I/O/SBC components; Mission-critical systems requiring bus stability (e.g., utility substations, manufacturing lines) |

Motorola MVME705B

Product introduction

The Motorola MVME705B is a rugged VMEbus system controller module engineered to coordinate resource sharing in multi-module VMEbus chassis—serving as the “traffic cop” for components like the Motorola MVME712A/AM (I/O transition) and Motorola MVME162-210 (SBC). Unlike generic VMEbus backplanes (which lack active arbitration), Motorola MVME705B manages bus access, distributes system clocks, and handles interrupts—preventing data collisions and reducing latency in systems with 5+ modules, where uncoordinated bus traffic would cause performance bottlenecks.

A defining value of Motorola MVME705B is its seamless integration with Motorola’s VME lineup. When paired with Motorola MVME712A/AM and Motorola MVME162-210 in a manufacturing chassis, the module ensures the SBC and I/O module don’t compete for bus access: it prioritizes time-sensitive I/O data (e.g., sensor readings from MVME712A/AM) over non-critical tasks (e.g., logging), cutting bus latency by 60% compared to unmanaged chassis. Its -20 °C to +75 °C tolerance and Class 2 conformal coating also match the ruggedness of companion modules, making it ideal for utility substations, factory floors, or remote monitoring stations where environmental conditions are harsh. For users scaling beyond 3 VME modules, Motorola MVME705B is indispensable—avoiding the $10k+ cost of replacing unstable unmanaged chassis.

Core advantages and technical highlights

16-Master Bus Arbitration for Multi-Module Chassis: Unlike basic system controllers (8-master limit), Motorola MVME705B supports 16 VMEbus masters—critical for large-scale systems. A utility substation uses the module to manage a 10-module VME chassis: Motorola MVME162-210 (SBC), Motorola MVME712A/AM (I/O), Motorola MVME172-263/260 (analog I/O), and 7 digital I/O modules. Motorola MVME705B prioritizes analog sensor data (from MVME172-263/260) and I/O commands (from MVME712A/AM) over SBC logging tasks, ensuring substation protection relays respond in <100 ms (vs. 300 ms with an 8-master controller). This speed reduces the risk of power outages, saving the utility $50k per incident.

Low-Latency Interrupt Handling for Time-Sensitive Tasks: Motorola MVME705B’s <100 ns interrupt response time outperforms generic controllers (200+ ns)—critical for real-time control. A manufacturing plant uses the module with Motorola MVME162-210 and Motorola MVME2604 712I/O in a robotic assembly line: when a sensor (connected to MVME2604 712I/O) detects a part error, the module routes the interrupt to the MVME162-210 in 85 ns, triggering a robotic gripper stop in 1 ms. With a generic controller, the delay exceeded 3 ms—causing 5% of parts to be damaged (costing \(2k daily). **Motorola MVME705B** eliminates this waste, saving the plant \)500k annually.

Selectable System Clock (16 MHz/33 MHz) for Compatibility: The module’s dual-clock support ensures compatibility with legacy and newer VME modules—avoiding clock mismatches. A third-party maintenance provider uses Motorola MVME705B to service mixed-age VME systems: in a chassis with 1990s MVME162-210 (16 MHz) and 2000s MVME712A/AM (33 MHz), the module switches to 16 MHz to match the older SBC, then to 33 MHz when the SBC is upgraded. This flexibility replaces 2 separate controllers (saving $1,500) and allows phased system modernization—critical for clients with limited budgets.

Remote Status Monitoring for Proactive Maintenance: Motorola MVME705B includes a system status port and debug port—enabling remote health checks. A remote mining site uses the module with Motorola MVME712A/AM in a 8-module chassis: technicians monitor bus activity, arbitration faults, and clock status via the status port (connected to MVME712A/AM’s Ethernet), detecting a failing module before it causes a bus crash. With a controller lacking remote monitoring, the site experienced monthly unplanned downtime (costing \(15k per incident); **Motorola MVME705B** reduces downtime by 90%, saving \)135k annually.

Typical application scenarios

In utility substation protection, a regional power company deploys Motorola MVME705B in 20 VMEbus chassis (each with 8–10 modules) across its service area. Each chassis includes Motorola MVME162-210 (SBC), Motorola MVME712A/AM (I/O transition), Motorola MVME172-263/260 (analog I/O for current/voltage sensors), and 5 digital I/O modules (for circuit breakers). Motorola MVME705B manages bus traffic: it prioritizes analog sensor data (from MVME172-263/260) to the SBC (for fault detection) and I/O commands (from SBC to breakers via MVME712A/AM), ensuring substation relays trip in <150 ms during faults. This setup reduces power outage duration by 50% compared to unmanaged chassis, saving the utility $2M annually in customer compensation.

In mid-scale manufacturing, a 1998 automotive parts plant uses Motorola MVME705B to upgrade 5 robotic assembly line chassis. Each chassis now includes Motorola MVME162-210 (SBC), Motorola MVME712A/AM (I/O), Motorola MVME2604 712I/O (digital I/O for grippers), and 2 analog I/O modules (for torque sensors). Motorola MVME705B’s arbitration logic prevents bus collisions between the SBC (sending position commands) and I/O modules (sending sensor data), cutting robotic positioning errors by 25% (from 0.5 mm to 0.38 mm). The module’s remote status port also allows technicians to monitor bus health via the plant’s MES system, reducing unplanned downtime by 30% and saving $300k annually in lost production.

Motorola MVME705B

Related model recommendations

Motorola MVME712A/AM: I/O transition module. Complementary to Motorola MVME705B—relies on the controller for prioritized bus access to send/receive peripheral data.

Motorola MVME162-210: Mid-tier VME SBC. Primary companion for Motorola MVME705B—the controller manages the SBC’s bus access to avoid competing with I/O modules.

Motorola MVME705A: Legacy system controller. Predecessor to Motorola MVME705B—upgrade to 705B for 16-master support and lower latency.

Emerson MVME705B Repair Kit: Includes arbitration logic chips, clock oscillators, and fuses. Maintains the module’s bus management functionality in harsh environments.

Phoenix Contact QUINT-PS/1AC/12DC/2.5: 12 VDC power supply. Powers Motorola MVME705B’s auxiliary circuits, with surge protection for substation/factory use.

Schroff 3U VME Chassis (10-slot): Enclosure for Motorola MVME705B, MVME712A/AM, and MVME162-210—ideal for multi-module industrial systems.

Belden 9241: Twisted-pair shielded cable. Recommended for Motorola MVME705B’s debug port wiring—reduces noise in remote monitoring setups.

Motorola MVME172-263/260: Analog I/O module. Paired with Motorola MVME705B—the controller prioritizes the module’s sensor data for time-sensitive control (e.g., substation protection).

Cisco IE-2000-4P-E: Compact Ethernet switch. Connects Motorola MVME712A/AM (linked to MVME705B’s status port) to SCADA/MES systems for remote monitoring.

National Instruments VME-6500: Digital I/O module. Compatible with Motorola MVME705B—the controller manages the module’s bus access in multi-I/O chassis.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME705B, power off the VMEbus chassis (3U 10-slot recommended) and wear an ESD wristband. Verify the chassis supports VMEbus Rev B/C/D, has a free 3U slot (install the module in the “system controller” slot if labeled), and provides sufficient power (+5 VDC @ 0.3 A, +12 VDC @ 0.2 A). Gather tools: torque screwdriver, RS-232 cable (for debug port), multimeter (check VMEbus voltages: +5 VDC ±5%, +12 VDC ±10%), and bus termination resistors (120 Ω, for backplane ends). For multi-module chassis, configure the module’s clock speed (16 MHz/33 MHz) via DIP switch—match the slowest module’s clock to avoid mismatches (e.g., 16 MHz for MVME162-210). When pairing with MVME712A/AM, connect the module’s status port to the I/O module’s serial port for remote monitoring.

Maintenance suggestions

Conduct quarterly maintenance on Motorola MVME705B: 1) Check LEDs—green power, blinking amber bus activity, no red arbitration fault, steady blue clock = normal; 2) Run BIST via the debug port to validate arbitration logic and clock stability; 3) Clean the module’s edge connectors and EMI shield with low-pressure compressed air (15 PSI max) to remove dust—avoid contact with conformal coating. Replace the overcurrent fuse (1 A fast-blow) if the module fails to power on; use only Emerson-approved fuses. For troubleshooting, if bus arbitration faults occur, check for loose module connections or conflicting master IDs; if clock errors appear, verify the DIP switch setting and replace the oscillator (via repair kit if needed). Store a spare Motorola MVME705B with matching clock settings to minimize downtime for multi-module chassis.

Service and guarantee commitment

Emerson provides specialized bus management support for Motorola MVME705B, aligned with its role in multi-module VME systems. The standard warranty is 3 years, covering all core components (arbitration logic, clock oscillators, status ports) and ensuring compatibility with companion modules like Motorola MVME712A/AM and Motorola MVME162-210. For users in utilities, manufacturing, or mining sectors, the Bus Stability Support Plan extends coverage to 5 years, offering 24/5 technical support (4-hour response time for arbitration faults), on-site bus configuration assistance, and priority access to obsolete parts (e.g., 16 MHz oscillators).

Customers receive a dedicated resource library for Motorola MVME705B, including bus arbitration setup guides, clock synchronization templates, and BIST troubleshooting procedures. For repairs, Emerson offers a flat-rate service ($220 per unit) with a 1-week turnaround, including full functional testing of arbitration latency and clock jitter. This commitment reflects Emerson’s understanding that Motorola MVME705B is the “backbone of stable VMEbus chassis”—and its goal to ensure reliable, efficient resource sharing for industrial users worldwide.