Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME5500 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Single-Board Computer (SBC) – High-Performance Industrial Control Core |

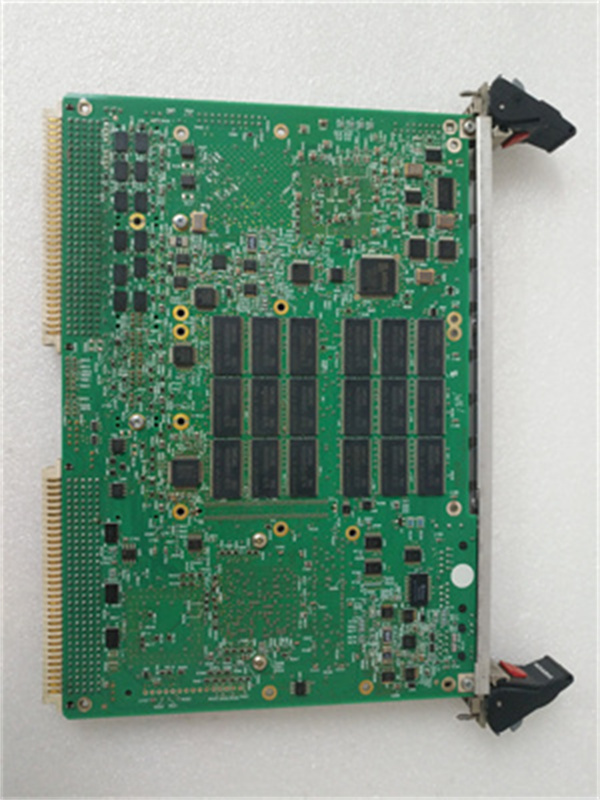

| CPU Configuration | PowerPC 7457 (G4) processor; 1.0 GHz clock speed; 512 KB L2 cache (on-chip) |

| Memory Capacity | 1 GB DDR SDRAM (expandable to 2 GB) – ECC (Error-Correcting Code) supported; 128 MB Flash ROM (for firmware/boot code); 4 GB CompactFlash slot (for storage expansion) |

| Bus Standard | VMEbus (PICMG VME 3.0 compliant) – 32/64-bit address/data bus; master/slave dual-mode; VME64x support for high-speed data transfer |

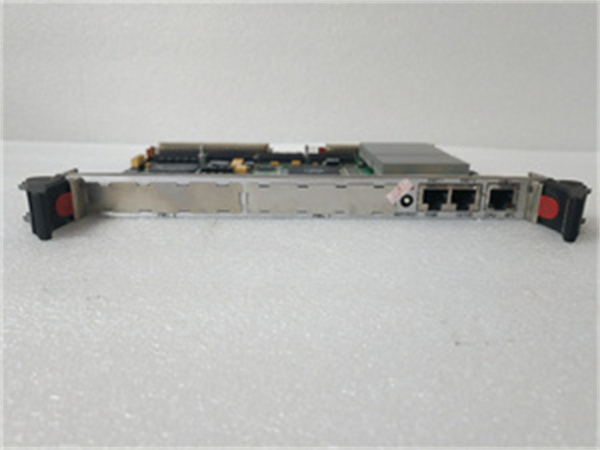

| Physical Dimensions | Standard 6U VME form factor (233.4 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (4.0 A typical, 6.0 A maximum); +12 VDC (0.8 A typical); -12 VDC (0.5 A typical); passive heat dissipation (heatsink-based) |

| Communication Interfaces | 2x Gigabit Ethernet ports (RJ45, IEEE 802.3ab compliant); 2x RS-232/422/485 serial ports (DB9, software-selectable); 1x USB 2.0 port; 1x VGA port (for local HMI); 1x JTAG port (for debugging) |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F) (extended industrial temperature grade) |

| Product Status | Active (supported by Emerson; replacement for legacy MVME SBCs like MVME172-263/260) |

| Compliance Standards | VME 3.0; IEEE 802.3ab (Gigabit Ethernet); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| On-Board Features | Watchdog timer (programmable 1ms–1hr timeout); real-time clock (RTC) with battery backup; hardware-based encryption (AES-128) for data security; built-in self-test (BIST) |

| Compatibility | Backward-compatible with legacy VME modules (Motorola MVME162PA-344E, Motorola MVME162-533A, Motorola MVME712/M); works with power modules (Motorola FAB 0340-1049, Motorola 30-W2960B01A) |

Product Introduction

The Motorola MVME5500 is a high-performance VMEbus single-board computer (SBC), designed to serve as the control core for modern industrial automation systems while retaining full compatibility with legacy VME peripherals. As a 6U VME form factor device, it represents a significant upgrade from older Motorola SBCs like the Motorola MVME172-263/260, leveraging a 1.0 GHz PowerPC G4 processor and ECC DDR SDRAM to handle compute-intensive tasks—from real-time control algorithms to high-volume data processing for precision modules like the Motorola MVME162PA-344E.

A defining strength of the Motorola MVME5500 is its seamless backward compatibility with the broader Motorola VME ecosystem. Its VME 3.0 compliance (including VME64x support) enables it to communicate with legacy analog input modules (Motorola MVME162PA-344E), I/O modules (Motorola MVME162-533A), and communication modules (Motorola MVME712/M) without hardware modifications. This compatibility allows end-users to modernize their control systems incrementally—replacing only the SBC while retaining existing peripherals—reducing upgrade costs by 30–50% compared to a full system overhaul.

Whether deployed in manufacturing process control, aerospace test benches, or energy monitoring systems, the Motorola MVME5500 delivers industrial-grade reliability and performance. Its extended temperature range (-40°C–70°C) and ECC memory ensure stable operation in harsh environments, while Gigabit Ethernet and USB connectivity enable integration with modern HMI and cloud-based monitoring platforms. These features make it the ideal choice for users seeking to extend the lifespan of their VME infrastructure while adding modern functionality.

Core Advantages and Technical Highlights

Advanced PowerPC Processing for Compute-Intensive Tasks

The Motorola MVME5500’s 1.0 GHz PowerPC G4 processor (with 512 KB L2 cache) delivers 5x the processing power of legacy SBCs like the Motorola MVME172-263/260 (33 MHz 68040). This performance leap is critical for applications requiring simultaneous handling of multiple tasks—such as processing 14-bit analog data from the Motorola MVME162PA-344E (200 kSPS aggregate) while running complex PID control loops and transmitting data to a SCADA system via Gigabit Ethernet. The on-chip L2 cache reduces memory latency, ensuring real-time responsiveness even under maximum load—essential for time-critical processes like semiconductor wafer etching or turbine control.

ECC Memory and Hardware Encryption for Data Integrity & Security

Unlike legacy SBCs, the Motorola MVME5500 supports ECC DDR SDRAM, which detects and corrects single-bit errors (and detects multi-bit errors) to prevent data corruption. This is invaluable for applications like medical device testing or nuclear power plant monitoring, where even a single bit error in sensor data could lead to catastrophic outcomes. Additionally, the module’s hardware-based AES-128 encryption protects sensitive data (e.g., process recipes, calibration logs) during transmission to cloud platforms or remote control centers—addressing modern industrial cybersecurity requirements that older SBCs cannot meet.

VME64x Support for High-Speed Peripheral Communication

The Motorola MVME5500’s compliance with VME 3.0 (including VME64x) enables 64-bit data transfers at speeds up to 320 MB/s—8x faster than the 16-bit VMEbus used by legacy modules like the Motorola MVME172-263/260. This high-speed bus is critical for leveraging the full capabilities of precision modules like the Motorola MVME162PA-344E: it allows the SBC to capture 14-bit analog data at 200 kSPS without bottlenecks, ensuring no transient events (e.g., 10 ms voltage spikes) are lost. For example, in a battery testing system with 16 channels of data, the VME64x bus ensures the Motorola MVME5500 processes and stores every sample in real time, enabling accurate analysis of charge/discharge cycles.

Extended Temperature Range and Rugged Design

With an operating temperature range of -40°C–70°C, the Motorola MVME5500 outperforms legacy SBCs (typically 0°C–60°C) and even enhanced modules like the Motorola MVME162PA-344E (-10°C–70°C). This makes it suitable for extreme environments: from arctic oil pipelines (-40°C) to desert-based solar farms (70°C). Its passive heatsink design eliminates fan-related failures, a common issue in dusty or humid industrial settings (e.g., food processing plants), while its RoHS compliance ensures compatibility with global environmental regulations. The module’s RTC with battery backup also retains critical system time during power outages, avoiding the need for reconfiguration when power is restored.

Typical Application Scenarios

The Motorola MVME5500 excels as a control core for modernized VME systems, integrating legacy peripherals like the Motorola MVME162PA-344E and Motorola MVME712/M with modern networks. In semiconductor manufacturing, it manages a wafer etching process: the SBC processes 14-bit plasma sensor data from the Motorola MVME162PA-344E (capturing microvolt-level fluctuations) to adjust RF power in real time. Its Gigabit Ethernet port transmits process data to a central MES system, while ECC memory ensures no data corruption occurs during transmission—critical for meeting nanometer-scale manufacturing tolerances. The module’s -40°C–70°C range also withstands the extreme temperatures of cleanroom facilities.

In aerospace engine testing, the Motorola MVME5500 serves as the control core for a test bench: it collects data from 8x Motorola MVME162PA-344E modules (monitoring fuel pressure, temperature, and vibration) at 200 kSPS aggregate. Its PowerPC processor runs complex data analysis algorithms to detect engine anomalies (e.g., 5 mV fuel pressure spikes), while hardware encryption secures test data during transmission to a remote engineering team. The SBC’s VME64x bus ensures high-speed communication with the Motorola MVME712/M (transmitting data to a SCADA system), and its passive cooling design avoids contamination in the test chamber—essential for aerospace-grade testing standards (e.g., DO-160).

For smart grid substation monitoring, the Motorola MVME5500 integrates with legacy and modern components: it reads voltage/current data from the Motorola MVME162PA-344E (connected to substation sensors) and communicates with modern IoT gateways via USB. Its AES-128 encryption protects sensitive power grid data during transmission to a cloud-based monitoring platform, while ECC memory prevents data corruption from electrical interference (common in high-voltage substations). The module’s extended temperature range (-40°C–70°C) withstands the harsh outdoor conditions of substations, and its watchdog timer automatically resets the system in case of software faults—ensuring 24/7 reliability for critical energy infrastructure.

MOTOROLA MVME5500

Related Model Recommendations

Motorola MVME172-263/260: Legacy VME SBC. Predecessor to Motorola MVME5500; 33 MHz 68040 CPU. Replaced by the MVME5500 for applications needing higher processing power (e.g., data-intensive monitoring).

Motorola MVME162PA-344E: Enhanced analog input module. Key peripheral for Motorola MVME5500; the SBC processes its 14-bit data to execute control logic—ideal for precision applications (e.g., semiconductor testing).

Emerson MVME5500-1000: Updated variant of Motorola MVME5500. Adds 2x additional Gigabit Ethernet ports and 8 GB CompactFlash support, optimized for large-scale industrial IoT (IIoT) deployments.

Motorola MVME712/M: VME communication module. Complements Motorola MVME5500; transmits the SBC’s processed data to SCADA/DCS systems via Ethernet/serial—enabling remote monitoring.

Motorola FAB 0340-1049: Power supply module. Primary power source for Motorola MVME5500; delivers stable ±12 VDC and +5 VDC to support the SBC’s high-power CPU and memory.

Emerson RSTi-EP Ethernet I/O: Modern Ethernet-based I/O modules. Paired with Motorola MVME5500 (via Gigabit Ethernet) for hybrid VME-Ethernet systems; expands connectivity to modern sensors/actuators.

Motorola MVME162-533A: Analog I/O module. Works with Motorola MVME5500 in closed-loop control systems; the SBC uses its input data to generate output signals for actuators (e.g., valves, pumps).

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME5500, power off the VME chassis and disconnect the Motorola FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis supports 6U VME modules and that the VME backplane is VME 3.0 compliant (for VME64x functionality). Check the power supply capacity: ensure it can deliver +5 VDC (6.0 A max), +12 VDC (0.8 A), and -12 VDC (0.5 A) to avoid underpowering the SBC’s CPU and memory. Use an anti-static wristband and mat to protect the module’s ECC DDR SDRAM and PowerPC processor from ESD damage. Gather tools: Phillips-head screwdriver (for chassis mounting), Gigabit Ethernet cable (Cat6 or higher), and a USB drive (for firmware updates). Avoid installing near high-voltage equipment (e.g., transformers) or heat sources (e.g., power resistors) to prevent EMI or thermal throttling.

Commissioning and Maintenance

For commissioning, insert the Motorola MVME5500 into the VME slot and secure it. Power on the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, then check the module’s LEDs: green “POWER” confirms voltage; solid “CPU ACTIVE” indicates processor operation; “ECC OK” (green) signals no memory errors. Connect a USB drive with the latest firmware to the SBC’s USB port and update the Flash ROM (follow Emerson’s firmware update guide). Configure the VMEbus settings (32/64-bit mode) via the on-board BIOS utility to match legacy peripherals (e.g., Motorola MVME162PA-344E). Test communication by pinging the SBC’s Gigabit Ethernet port from a SCADA workstation and verifying data transfer from the Motorola MVME162PA-344E to the SBC.

For maintenance: Inspect the module’s heatsink quarterly—clean dust with compressed air (low pressure) to prevent overheating. Back up the Flash ROM firmware annually to a USB drive; update firmware semi-annually to address security vulnerabilities and improve compatibility. Monitor ECC memory errors via the SBC’s diagnostic software—replace memory modules if multi-bit errors are detected. Check the RTC battery every 3–5 years (replace with a CR2032 battery) to retain system time during power outages. If the watchdog timer triggers, use the JTAG port to debug software faults or revert to a previous firmware version. When upgrading from a legacy SBC (e.g., Motorola MVME172-263/260), replicate the control logic in the Motorola MVME5500’s software to ensure backward compatibility with existing peripherals.

Service and Guarantee Commitment

The Motorola MVME5500 is an active product supported by Emerson, and we offer a 3-year standard warranty on new units—covering defects in materials, workmanship, ECC memory functionality, and CPU performance. Each new module undergoes rigorous testing: 100-hour burn-in at -40°C–70°C (validates thermal stability), ECC memory error injection testing (confirms error correction), and VME64x bus speed validation (ensures 320 MB/s transfers). Refurbished units come with a 1-year warranty, with the same testing standards applied.

Our technical support team (24/7 availability) specializes in Motorola MVME5500 integration, firmware updates, and VMEbus troubleshooting—including optimizing communication with legacy modules like the Motorola MVME162PA-344E and Motorola MVME712/M. We offer customized maintenance plans: annual on-site inspections (cleaning heatsinks, testing ECC memory) and remote firmware monitoring (via Gigabit Ethernet) to proactively address issues. Our spare parts inventory includes critical components (e.g., PowerPC processors, ECC DDR SDRAM) for fast repairs—minimizing downtime in mission-critical applications.

For users modernizing legacy VME systems, we provide free migration consultations: our engineers help replicate control logic from older SBCs (e.g., Motorola MVME172-263/260) to the Motorola MVME5500 and ensure compatibility with existing peripherals. We also offer training sessions on the SBC’s advanced features (e.g., hardware encryption, VME64x) to help teams maximize system performance. Our commitment to support ensures your Motorola MVME5500 remains a reliable control core for years to come.