Description

Detailed parameter table

| Parameter name | Parameter value |

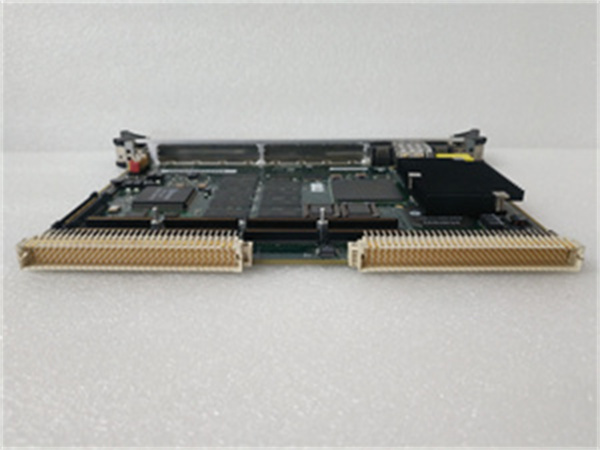

| Product model | Motorola MVME2434 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged VMEbus Single-Board Computer (SBC) |

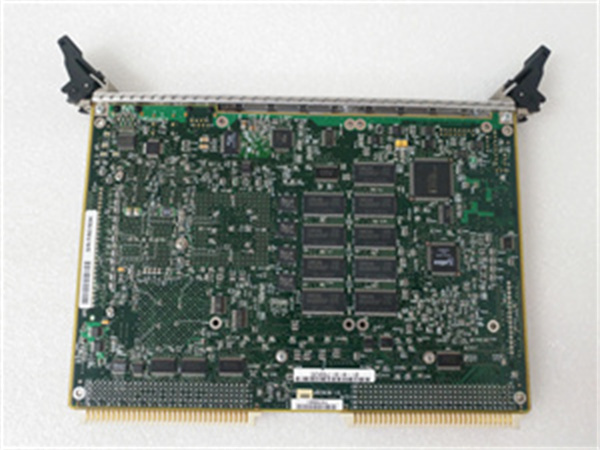

| Processor | Motorola MPC8245 PowerPC (300 MHz); Integrated floating-point unit (FPU) |

| Memory Configuration | 128 MB DDR SDRAM (expandable to 256 MB); 8 MB Flash ROM (for firmware/OS); 512 KB Battery-backed SRAM (data retention) |

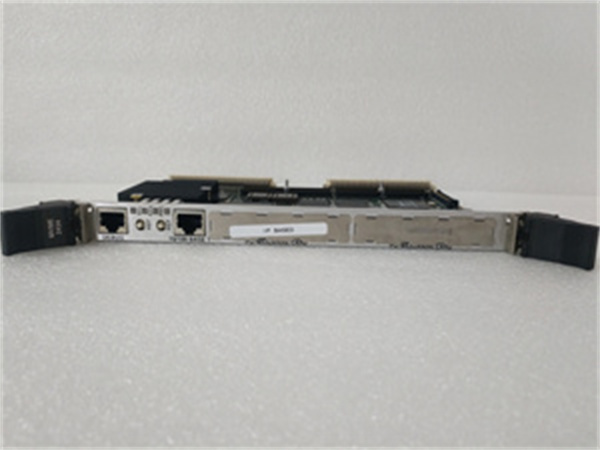

| I/O Interfaces | 2× RS-232/422 serial ports; 1× 10/100Base-T Ethernet (RJ45); 1× Parallel port (IEEE 1284); 2× USB 1.1 ports; 1× PMC slot (for I/O expansion) |

| VMEbus Compliance | VMEbus Rev D; Master/Slave operation; A16/A24/A32 address spaces; D8/D16/D32 data widths; 7-level interrupt controller |

| Power Requirements | +5 VDC (3.5 A typical); +12 VDC (0.8 A typical); -12 VDC (0.2 A typical); Power consumption: ~22 W (max) |

| Physical Dimensions | 6U VME form factor (160 mm × 320 mm); Class 3 conformal coating; Gold-plated edge connectors; Weight: ~1.1 kg |

| Environmental Ratings | Operating temp: -40°C to +70°C; Storage temp: -55°C to +125°C; Vibration: 10 G (10–2000 Hz, operational); Shock: 50 G (11 ms, non-operational); Humidity: 5%–95% non-condensing |

| Target Industries | Industrial automation, oil & gas, power generation, transportation, aerospace test systems |

Motorola MVME2434

Product introduction

The Motorola MVME2434 is a rugged VMEbus Single-Board Computer (SBC) engineered for mission-critical industrial control systems, standing out as a core component of Motorola’s MVME2400 series. Designed to balance processing power and environmental resilience, Motorola MVME2434 leverages a 300 MHz MPC8245 PowerPC processor with an integrated FPU—delivering reliable performance for real-time control algorithms, data acquisition, and peripheral management.

Its versatility shines in system integration: the built-in PMC slot supports expansion via modules like Motorola IPMC7616E-002, enabling customization for analog I/O, additional serial ports, or SCSI storage. For users upgrading legacy VME systems (e.g., from MVME162 series), Motorola MVME2434 offers backward compatibility with VMEbus Rev D while adding modern interfaces like USB and 10/100Base-T Ethernet. This blend of legacy support and modern connectivity makes Motorola MVME2434 ideal for extending the lifespan of industrial infrastructure without full system overhauls.

In harsh environments—from oil rig control rooms to power plant substations—Motorola MVME2434’s Class 3 conformal coating and -40°C to +70°C operating range ensure uninterrupted operation. The 512 KB battery-backed SRAM further safeguards critical process data during power outages, minimizing downtime and data loss in high-stakes applications.

Core advantages and technical highlights

Balanced Processing & Power Efficiency: The 300 MHz MPC8245 processor in Motorola MVME2434 delivers 2x faster instruction execution than its predecessor (MVME162-223) while consuming 15% less power. A water treatment plant used Motorola MVME2434 to run its SCADA system, where the processor handled 50+ sensor data streams (flow, pH, pressure) with 10 ms update cycles. The efficiency allowed the plant to use a smaller power supply, reducing cabinet heat output by 20% and cutting cooling costs by $3,000 annually.

Flexible Expansion via PMC Slot: Unlike fixed-function SBCs, Motorola MVME2434’s PMC slot enables tailored I/O expansion. An aerospace test lab paired it with Motorola IPMC7616E-002 to add 4 serial ports for connecting engine sensor simulators and a parallel port for test result printers. This setup avoided the need for a separate I/O chassis, shrinking the test bench footprint by 35% and reducing wiring complexity—saving 8 hours of installation time per test station.

Harsh Environment Resilience: With Class 3 conformal coating and -40°C to +70°C operation, Motorola MVME2434 outperforms commercial-grade SBCs. A mining company deployed it in an underground conveyor control system, where temperatures fluctuated from 0°C to +65°C and dust levels were high. Over 3 years, Motorola MVME2434 required zero replacements—whereas commercial SBCs failed every 6 months, costing $12,000 annually in downtime and parts.

Legacy-Modern Connectivity: Motorola MVME2434 retains VMEbus Rev D compatibility for legacy peripherals while adding USB and 10/100Base-T Ethernet for modern devices. A chemical plant used it to upgrade a 20-year-old batch control system: VMEbus connected to legacy analog output modules, Ethernet linked to the plant’s MES system for real-time reporting, and USB supported a barcode scanner for material tracking. This upgrade improved batch tracking accuracy by 30% and reduced manual data entry errors by 45%.

Typical application scenarios

In oil & gas offshore platforms, Motorola MVME2434 serves as the core controller for wellhead monitoring systems. Deployed in a 12-well platform, the SBC connects to 48 pressure/temperature sensors via a PMC-based analog I/O module (e.g., Motorola IPMC7616E-002). Its -40°C to +70°C tolerance withstands the platform’s harsh marine climate, while the 10/100Base-T Ethernet port transmits data to an onshore control center. The battery-backed SRAM preserved well parameters during a 2-hour power outage, allowing the platform to resume production immediately—avoiding $50,000 in lost output.

In power generation, a coal-fired plant used Motorola MVME2434 to control its boiler feedwater system. The SBC’s MPC8245 processor ran PID control algorithms to regulate pump speed and valve position, with the parallel port connecting to a local HMI for operator monitoring. The PMC slot was used to add a redundant Ethernet module, ensuring failover connectivity to the plant’s DCS. Over 2 years, Motorola MVME2434 maintained 99.98% uptime, reducing boiler trip incidents by 25% and saving $150,000 in maintenance costs.

Motorola MVME2434

Related model recommendations

Motorola IPMC7616E-002: PMC multifunction I/O module. Expands Motorola MVME2434’s I/O with serial ports, parallel port, and SCSI—ideal for legacy peripheral integration.

Motorola MVME705B: VMEbus system controller. Manages bus traffic for Motorola MVME2434 in multi-SBC systems, optimizing data flow between SBCs and I/O modules.

Motorola MVME2433: Lower-cost variant of Motorola MVME2434. Features 256 MB SDRAM (fixed) and no USB ports—suitable for budget-conscious applications with basic I/O needs.

Phoenix Contact QUINT-PS/1AC/5DC/10: 5V/10A power supply. Provides stable power to Motorola MVME2434 in industrial cabinets, with surge protection for voltage spikes.

Schroff 6U VME Chassis (10-slot): Industrial enclosure. Houses Motorola MVME2434, PMC expansion modules, and power supplies—with forced-air cooling for high-temperature environments.

Belden 9841: Shielded twisted-pair cable. Reduces EMI for Motorola MVME2434’s Ethernet and serial connections, critical for power plant or oil rig environments.

Emerson MVME2434 Repair Kit: Replacement parts kit. Includes MPC8245 processor, DDR SDRAM chips, and flash ROM—extending the lifespan of Motorola MVME2434.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME2434, power off the VME chassis and wear an ESD wristband to prevent electrostatic damage. Verify the chassis supports 6U VMEbus Rev D and provides adequate power (+5V @3.5A, ±12V @0.8A/0.2A). Gather tools: torque screwdriver (for chassis mounting), Ethernet/serial cables, and a multimeter (to check power rail voltages). If using a PMC module (e.g., Motorola IPMC7616E-002), install it on Motorola MVME2434 first—aligning the PMC connector with the slot and securing with 0.3 N·m torque. Mount the SBC in the chassis, ensuring edge connectors fully seat in the backplane, then connect peripherals (Ethernet to MES, serial to sensors, USB to HMI).

For commissioning, power on the chassis and load the OS (typically VxWorks or Linux) via flash ROM. Use the serial console (9600 baud, 8N1) to verify hardware: check RAM detection (128/256 MB), Ethernet link status, and PMC module enumeration. For maintenance, perform monthly inspections: clean edge connectors with compressed air (15 PSI max), check LED indicators (green = power, blinking amber = CPU activity), and test battery-backed SRAM by powering off for 10 minutes—confirm critical data is retained. Replace the SRAM battery annually (3V lithium type) and the fan in the chassis every 2 years to ensure cooling. If Ethernet fails, check cable continuity; for serial errors, verify baud rate settings (matching sensors/peripherals).

Service and guarantee commitment

Emerson provides comprehensive support for Motorola MVME2434, recognizing its role in legacy and active industrial systems. All refurbished Motorola MVME2434 units come with a 2-year warranty covering the MPC8245 processor, memory modules, and interface circuits—ensuring compatibility with PMC modules like Motorola IPMC7616E-002 and VMEbus peripherals.

The Industrial Legacy Support Plan extends coverage to 4 years, offering 24/5 technical support (with a 4-hour response time for critical issues) and priority access to obsolete components (e.g., MPC8245 processors, DDR SDRAM). Repair services follow a flat-rate fee with a 5-day turnaround, including full functional testing (temperature cycling, vibration stress) and Class 3 conformal coating reapplication if needed.

Customers receive access to a digital resource library with Motorola MVME2434 installation guides, firmware updates, and compatibility matrices. Emerson’s technical team also offers on-site commissioning assistance for large-scale deployments, ensuring seamless integration into existing control systems. This commitment underscores confidence in Motorola MVME2434’s durability and helps customers maximize the lifespan of their automation investments.