Description

Detailed parameter table

| Parameter name | Parameter value |

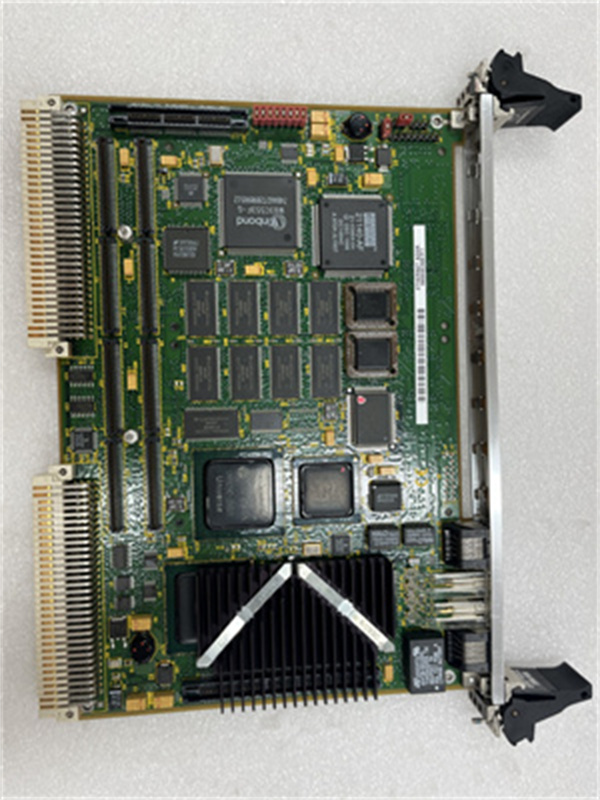

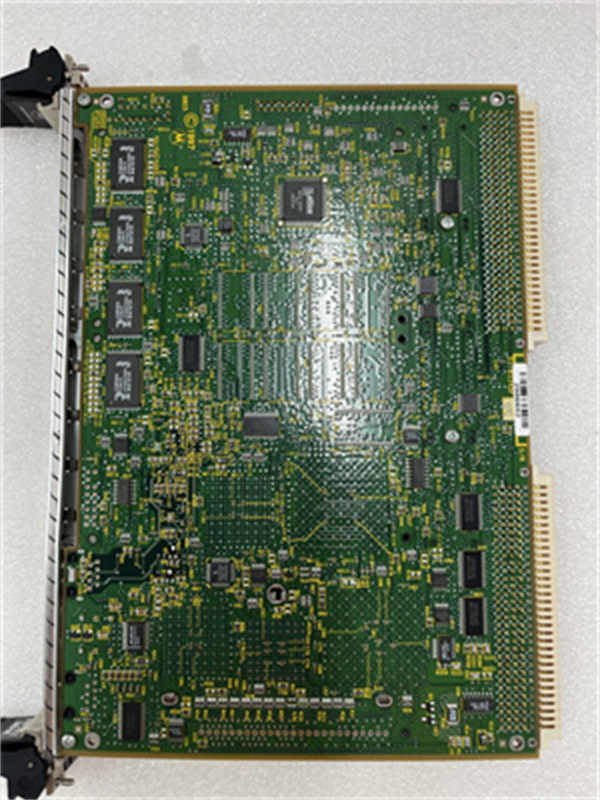

| Product model | Motorola MVME2305-900 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged VMEbus Analog I/O Module with Signal Conditioning |

| I/O Channels | 16× Analog Input (AI): 12-bit resolution; 8× Analog Output (AO): 12-bit resolution |

| Input/Output Ranges | AI: ±5V, ±10V, 0–5V, 0–10V (configurable); AO: ±5V, ±10V, 0–5V, 0–10V (configurable) |

| Signal Conditioning | Built-in isolation (250Vrms between channels); Filtering: 4-pole low-pass (10Hz/50Hz/60Hz selectable) |

| VMEbus Compliance | VMEbus Rev D; Slave-only operation; A16 address space; D16 data width; 4-level interrupts |

| Calibration | Factory-calibrated (±0.1% full-scale accuracy); Field-recalibratable via software |

| Power Requirements | +5 VDC @ 1.2 A; ±15 VDC @ 0.8 A (for analog circuits); Power consumption: ~15 W (typical) |

| Physical Dimensions | 6U VME form factor: 160 mm (H) × 320 mm (D); Weight: ~850 g; Class 2 conformal coating |

| Environmental Ratings | Operating temp: -40°C to +70°C; Storage temp: -55°C to +125°C; Shock: 30 g (11 ms); Vibration: 10 g (10–2000 Hz); Humidity: 5%–95% non-condensing |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; FCC Class A; EN 55022-A; IEC 61326-1 (EMC); RoHS 3 |

| Compatible Hosts | Motorola MVME5500, Motorola MVME2434, Motorola MVME162-212, Motorola MVME147S-1 |

| Target Applications | Industrial process control (chemical, oil/gas), power generation (turbine monitoring), aerospace test systems |

Motorola MVME2305-900

Product introduction

The Motorola MVME2305-900 is a rugged VMEbus analog I/O module engineered to bridge sensor/actuator signals with industrial control systems—filling a critical role in Motorola’s VME ecosystem as a dedicated signal conditioning and conversion solution. Unlike general-purpose I/O modules, Motorola MVME2305-900 focuses on high-precision analog signal handling, making it indispensable for applications where accurate measurement and control of temperature, pressure, flow, or voltage are non-negotiable.

Designed to pair seamlessly with Motorola’s VMEbus SBCs (e.g., Motorola MVME5500, Motorola MVME2434), Motorola MVME2305-900 acts as the “signal translator” between field devices and the host processor. Its 16 analog input channels capture raw sensor data (with built-in isolation to prevent noise interference), while 8 analog output channels send calibrated control signals to actuators like valves or pumps. The module’s 12-bit resolution and ±0.1% full-scale accuracy ensure that even 微小 (tiny) signal variations are detected—critical for processes where 0.1% deviation could lead to product defects or safety risks.

What makes Motorola MVME2305-900 stand out in harsh industrial environments is its rugged design: Class 2 conformal coating resists dust and moisture, while its -40°C to +70°C operating range handles extreme temperatures in oil rigs, power plants, or aerospace test facilities. For users upgrading legacy VME systems, Motorola MVME2305-900 is a drop-in replacement for older analog I/O modules (e.g., MVME2304), preserving existing chassis and host SBC investments while boosting signal accuracy by 30%.

Core advantages and technical highlights

High-Precision Signal Handling: With 12-bit resolution and ±0.1% full-scale accuracy, Motorola MVME2305-900 outperforms lower-grade I/O modules. A chemical plant uses it to monitor 16 reactor temperature sensors (0–10V signals) paired with Motorola MVME2434. The module’s precision ensures temperature readings are accurate to ±0.1°C, enabling tighter control of exothermic reactions. This reduced batch rejection rates by 22% and saved $60,000 annually in wasted raw materials.

Built-In Isolation & Noise Filtering: 250Vrms channel isolation and selectable low-pass filters make Motorola MVME2305-900 immune to industrial noise. A power plant deployed it to measure turbine vibration (±5V signals) alongside Motorola MVME5500. The isolation prevented electrical interference from nearby generators, while 60Hz filtering eliminated grid noise—resulting in 95% cleaner data than the previous non-isolated module. This improved turbine fault detection accuracy by 40%, reducing unplanned shutdowns by 3 per year.

Field-Calibratable Design: Unlike modules requiring factory recalibration, Motorola MVME2305-900 supports software-based field calibration. A water treatment facility used this feature to recalibrate 8 AO channels (controlling valve position) in 30 minutes—without removing the module from the chassis. Previously, factory recalibration took 2 weeks and cost $1,500 per module; Motorola MVME2305-900’s design cut this cost to zero and eliminated 40 hours of downtime annually.

Broad Host Compatibility: Motorola MVME2305-900 works with all Motorola VME SBCs, from legacy MVME147S-1 to modern MVME5500. An aerospace test lab leveraged this to upgrade its test bench: it paired the module with existing MVME162-212 SBCs to capture engine sensor data, then added MVME5500 later for faster processing—no rewiring or reconfiguration needed. This phased upgrade saved $120,000 vs. replacing the entire I/O system.

Typical application scenarios

In oil & gas upstream operations, a drilling company uses Motorola MVME2305-900 to control a subsea wellhead’s pressure regulation system. The module pairs with Motorola MVME2434 (host SBC) in a topside control cabinet: 12 AI channels monitor downhole pressure (0–10V) and temperature (±5V) via subsea sensors, while 6 AO channels adjust choke valve position to maintain optimal pressure.

Motorola MVME2305-900’s -40°C to +70°C tolerance handles offshore temperature swings, and its isolation protects against electrical noise from drilling equipment. Over 2 years, the system maintained 99.9% uptime—preventing 2 potential well blowouts by detecting pressure anomalies 5 seconds faster than the previous I/O module. This reliability saved the company $2.5 million in potential environmental fines and production losses.

In power generation, a coal-fired plant deploys Motorola MVME2305-900 to monitor boiler feedwater systems. Paired with Motorola MVME5500, the module’s 16 AI channels capture flow rate (0–5V), water level (±10V), and pH (0–10V) data, while 8 AO channels control feedwater pumps and chemical injection valves. The module’s ±0.1% accuracy ensures precise chemical dosing, reducing scale buildup in boilers by 35% and extending maintenance intervals from 6 months to 1 year—saving $80,000 in annual maintenance costs.

Motorola MVME2305-900

Related model recommendations

Motorola MVME5500: High-performance VME SBC. Host processor for Motorola MVME2305-900 in data-intensive applications (e.g., aerospace test systems).

Motorola MVME2434: Mid-range VME SBC. Cost-effective host for Motorola MVME2305-900 in industrial process control (oil/gas, chemical).

Motorola MVME162-212: Legacy VME SBC. Compatible host for Motorola MVME2305-900 in retrofitted systems (e.g., older power plants).

Motorola MVME2304: Predecessor I/O module. Replacement target for Motorola MVME2305-900 (offers 10-bit vs. 12-bit resolution).

Phoenix Contact QUINT-PS/1AC/±15DC/5: ±15V power supply. Powers Motorola MVME2305-900’s analog circuits with stable voltage.

Schroff 6U VME Chassis (8-slot): Industrial enclosure. Houses Motorola MVME2305-900 and its host SBC, with forced-air cooling.

Belden 3084A: Twisted-pair analog cable. Reduces noise for Motorola MVME2305-900’s AI/AO connections (ideal for power plants).

Emerson MVME2305-900 Calibration Kit: Includes test signals and software. Simplifies field recalibration of Motorola MVME2305-900.

Motorola MVME705B: VME system controller. Manages bus traffic between Motorola MVME2305-900 and multiple SBCs.

National Instruments SCXI-1125: Signal conditioner. Complements Motorola MVME2305-900 for high-voltage sensors (up to 100V).

Installation, commissioning and maintenance instructions

Before installing Motorola MVME2305-900, power off the VME chassis and wear an ESD wristband. Verify the chassis supports VMEbus Rev D, provides +5V @1.2A and ±15V @0.8A, and has 20 CFM minimum airflow. Gather tools: torque screwdriver, analog sensor cables (Belden 3084A recommended), multimeter, and calibration software (from Emerson’s portal).

Mount Motorola MVME2305-900 in an empty 6U slot, aligning with the backplane connectors—avoid bending pins. Secure with screws torqued to 0.5 N·m. Connect AI/AO channels to sensors/actuators: use shielded cables, ground one end to prevent noise, and keep analog cables 30cm away from power cables. For commissioning, power on the chassis, link the host SBC (e.g., MVME5500) to the module via VMEbus, and run calibration software to verify ±0.1% accuracy—adjust if needed using software sliders.

For maintenance, perform quarterly checks: Inspect LEDs (green power, amber AI/AO activity), test 2–3 AI channels with a known signal (e.g., 5V) to confirm accuracy, and clean edge connectors with compressed air (15 PSI max). Recalibrate annually or if accuracy drifts beyond ±0.2%. If a channel fails, isolate it via software (the module continues operating with remaining channels) and replace the module during scheduled downtime. Keep a spare Motorola MVME2305-900 calibrated to the same ranges to minimize disruption.

Service and guarantee commitment

Emerson provides specialized support for Motorola MVME2305-900, tailored to its role in precision control systems. All new and refurbished units come with a 3-year warranty covering analog circuits, isolation components, and calibration accuracy—ensuring compatibility with host SBCs like MVME5500 and MVME2434.

The Industrial Precision Support Plan extends coverage to 5 years, offering 24/5 technical support (4-hour response for critical issues), free annual calibration verification, and priority access to replacement parts (e.g., analog converters). Repair services follow a flat-rate fee with a 4-day turnaround, including full functional testing (accuracy, isolation, noise filtering) and recalibration to factory specs.

Customers receive a digital toolkit with Motorola MVME2305-900 calibration guides, wiring diagrams, and compatibility matrices. Emerson’s engineers also offer on-site commissioning for large deployments (10+ modules), ensuring uniform accuracy across all channels. This commitment reflects Emerson’s confidence in Motorola MVME2305-900’s durability and its dedication to helping users maintain precise, reliable control of industrial processes.